Shot blasting machine

A technology of shot blasting machine and high-pressure fan, which is applied in the direction of used abrasive processing devices, combined devices, abrasives, etc., can solve the problems of damaging the air environment of the factory building, affecting physical and mental health, and easily causing danger, so as to improve air quality, Improve the effect of back blowing and dust removal and reduce the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

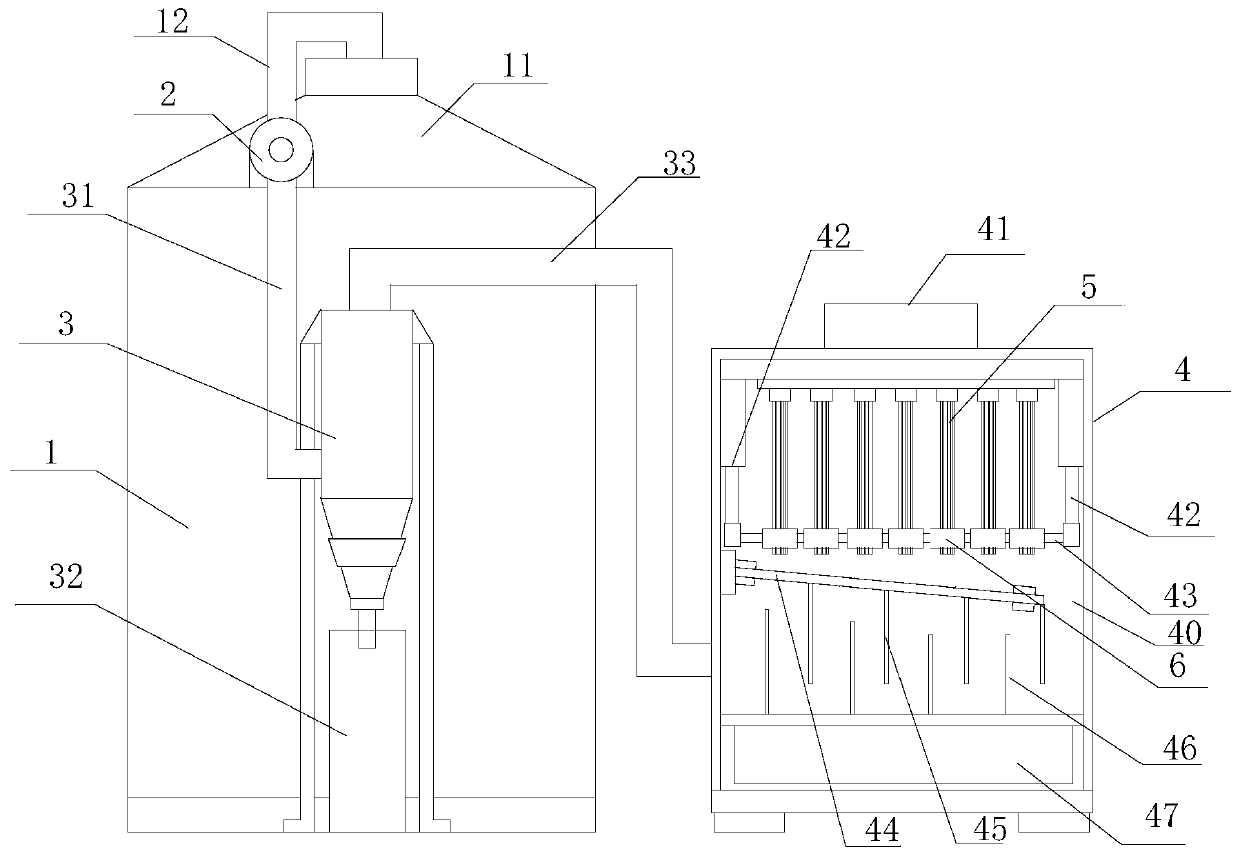

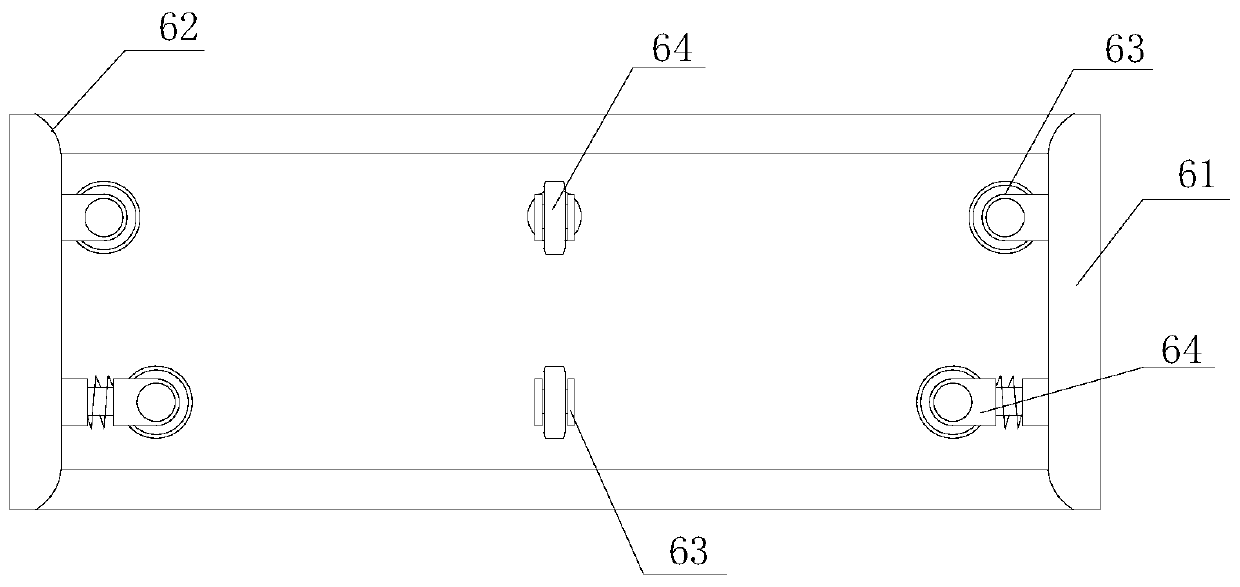

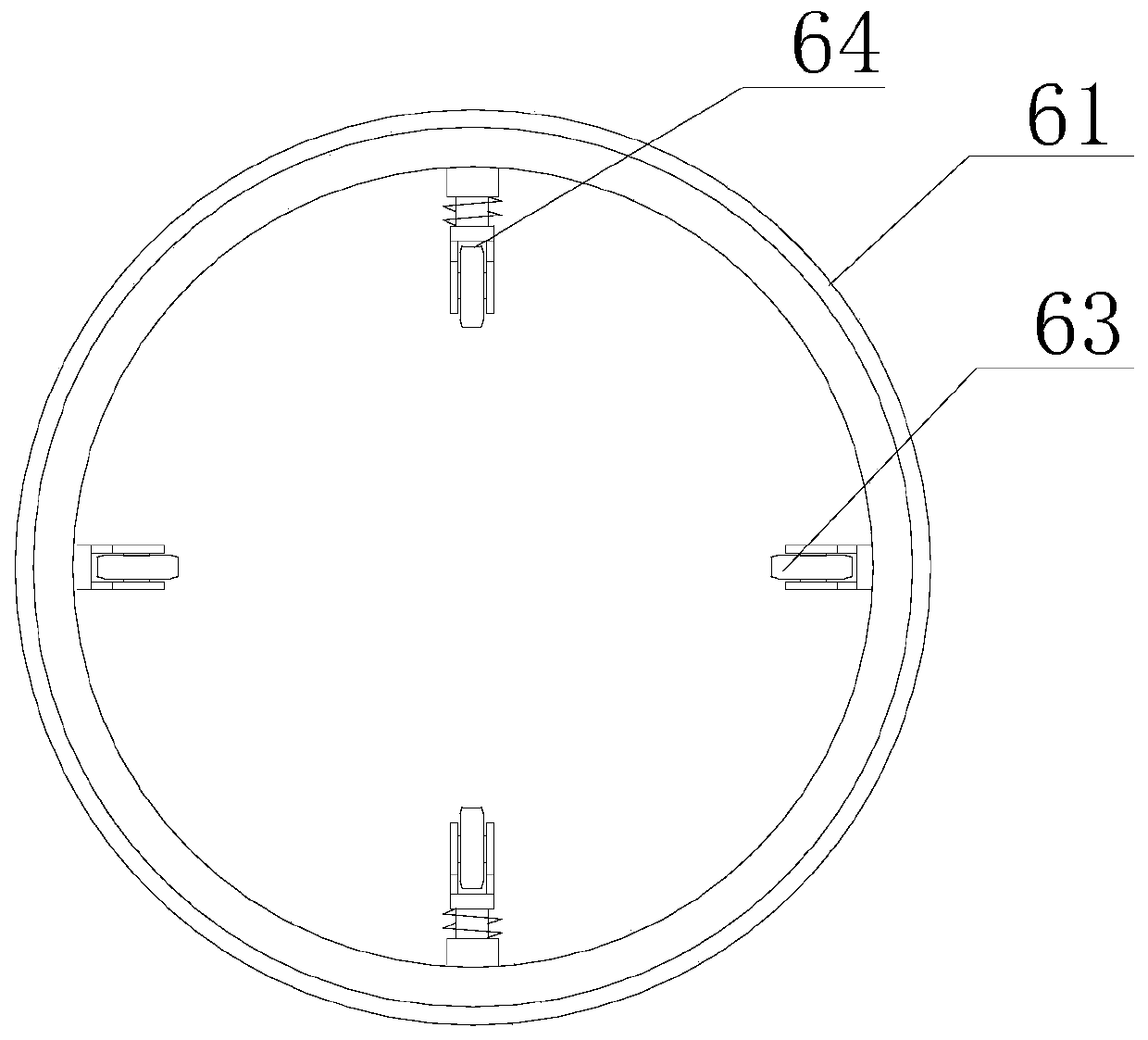

[0018] refer to Figure 1 to Figure 5 A shot blasting machine of the present invention comprises a shot blasting machine 1, a high-pressure fan 2, a cyclone separator 3, a bag dust removal box 4, a dust removal bag 5 and a shaking bag assembly 6, and the top of the shot blasting machine 1 is provided with a dust collection cover 11. The top of the dust collection hood 11 is connected to the high-pressure fan 2 through the first air duct 12, and the high-pressure fan 2 is connected to the side wall of the cyclone separator 3 through the second air duct 31, and the cyclone separator 3 The top communicates with the lower part of the bag dust removal box 4 through the third air pipe 33. The inner cavity of the bag dust removal box 4 is respectively provided with a first dust removal room and a second dust removal room from bottom to top. An installation support plate 44 is arranged between the two dust removal chambers, a plurality of upper partitions 45 are arranged at intervals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com