Material receiving buffer mechanism

A buffer mechanism and technology for incoming materials, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of safety impact of material quality operators, large impact force, flying out, etc., to avoid shock damage or flying out. , the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

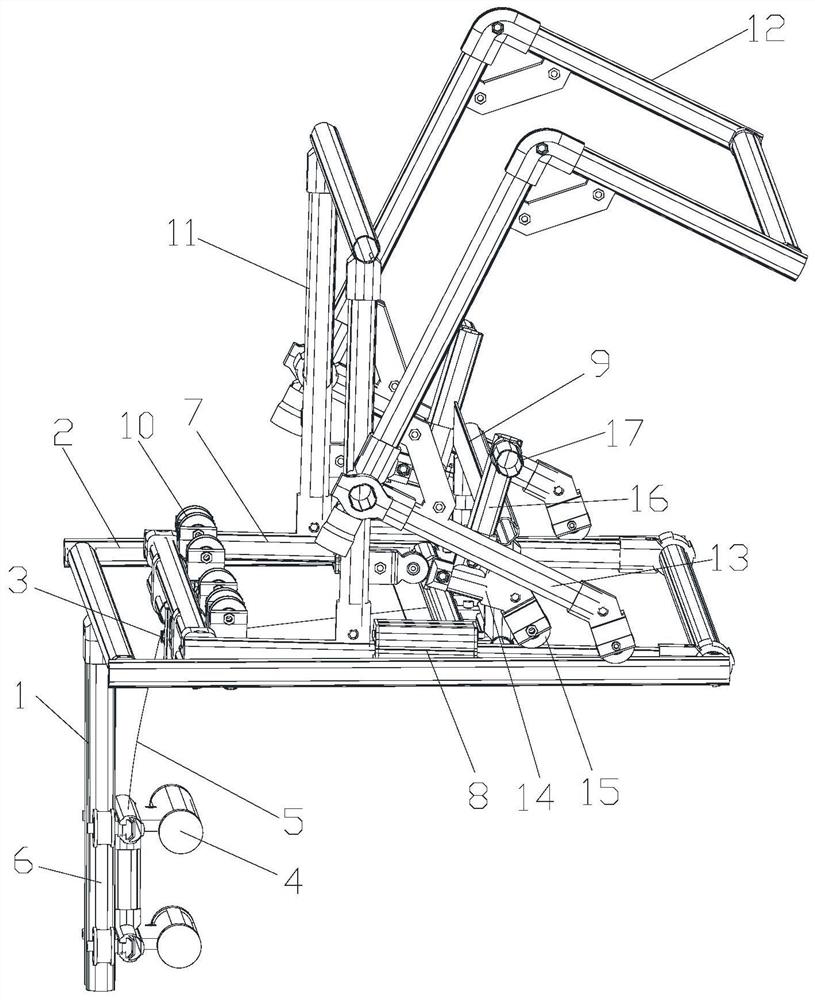

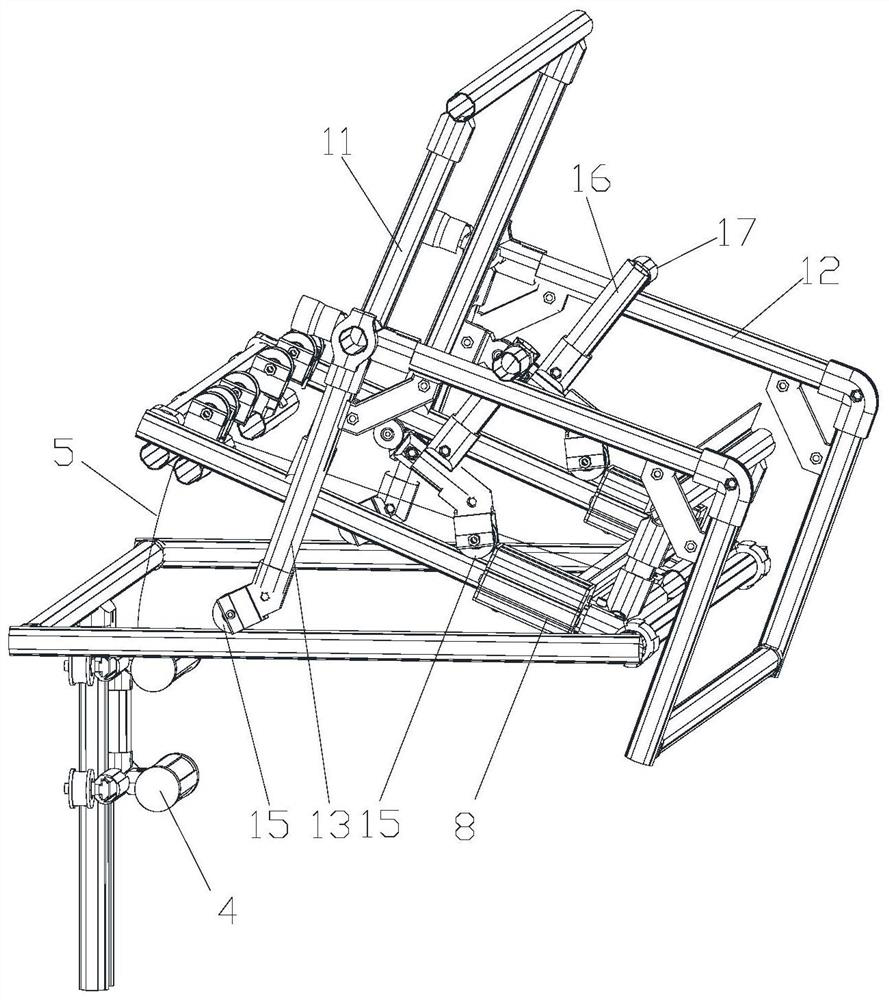

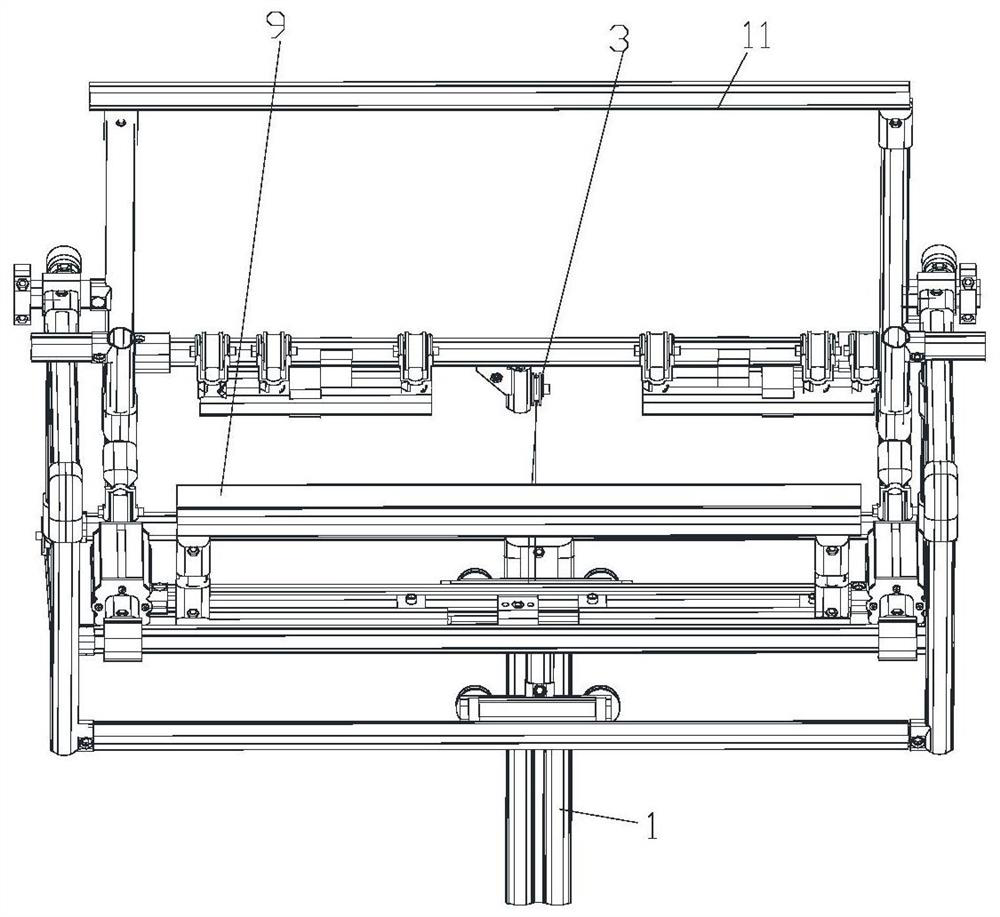

[0027] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present application, the material receiving buffer mechanism includes a material receiving part, a blocking part and a reaction unit, the material receiving part is used to accept incoming materials, and the blocking part is slidably arranged on the material receiving part for carrying The impact force forms a barrier to the incoming material, and the reaction unit is connected to the blocking part, and provides a reaction force opposite to the impact force of the incoming material to the blocking part.

[0028] The material-receiving buffer mechanism uses the material-receiving part to receive the material, and uses the blocking part slidingly arranged on the material-receiving part to block the material, so that after the incoming material reaches the material-receiving part, it can drive the blocking part to slide under the action of inertia, Since the blocking part is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com