Suspension bridge main cable structure utilizing ventilation steel pipes for dehumidification

A suspension bridge and steel pipe technology, which is used in bridges, bridge parts, bridge construction and other directions to achieve reliable dehumidification effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1 main cable of standard suspension bridge based on the present invention

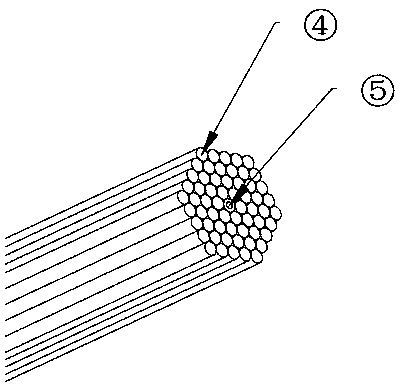

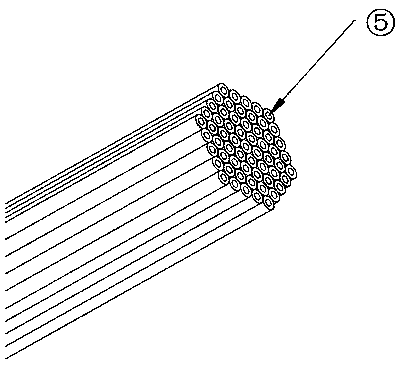

[0042] Due to certain differences in the length specifications of the main cables of suspension bridges, the number of parallel steel wires in the cable strands can be divided into 61, 91, and 127 according to the needs. In this example, 61 standard cable strands are used for illustration.

[0043] 1.1 Main cable specification

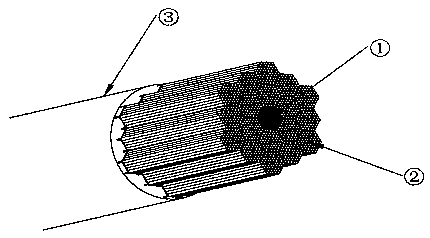

[0044] In this example, the number of strands used for the main cable is 19, of which, except for the central strand, the rest of the strands are force-bearing strands, a total of 18, see figure 1 .

[0045] 1.2 Stressed cable strand structure

[0046] The tensioned strands are all parallel steel wires except for a ventilation steel pipe in the center. The length of the parallel steel wire and the ventilation steel pipe is the same, usually related to the size of the applied bridge. The example of the present invention selects the parallel steel wire as φ5mm level. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com