Power module with moisture-proof and dehumidifying function, and moisture-proof and dehumidifying method of the same

A technology for power modules and functions, applied to power modules with moisture-proof and dehumidification functions and their moisture-proof and dehumidification fields, can solve the problems of inability to discharge condensed water from chips, unable to form cabinets, and long heating and dehumidification time, so as to achieve efficient treatment of condensation. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

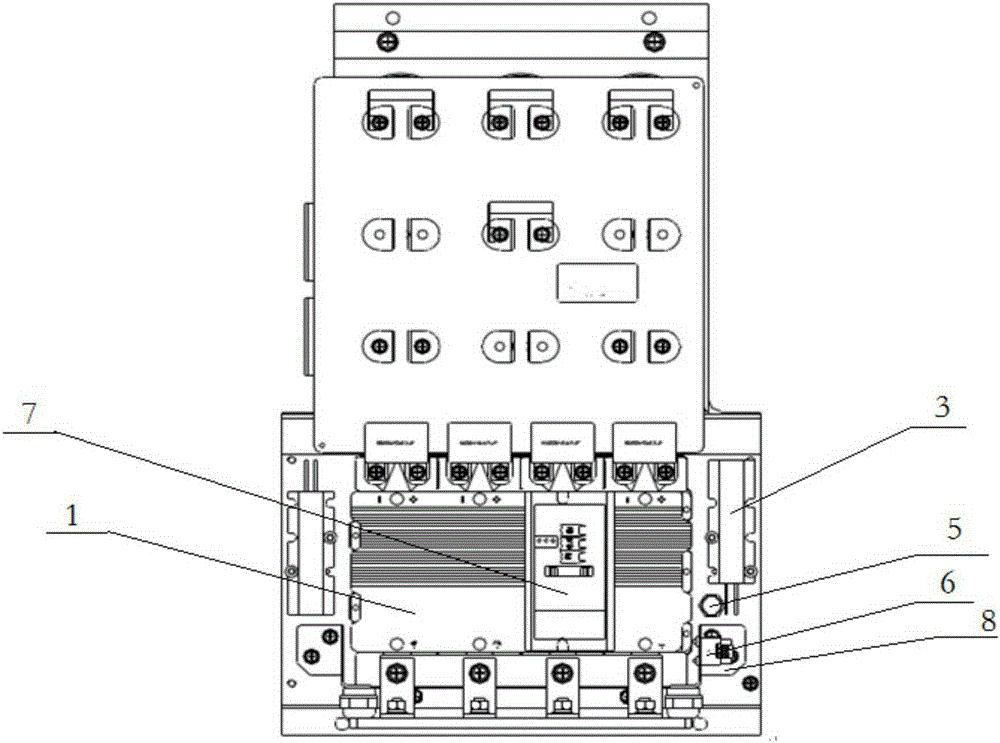

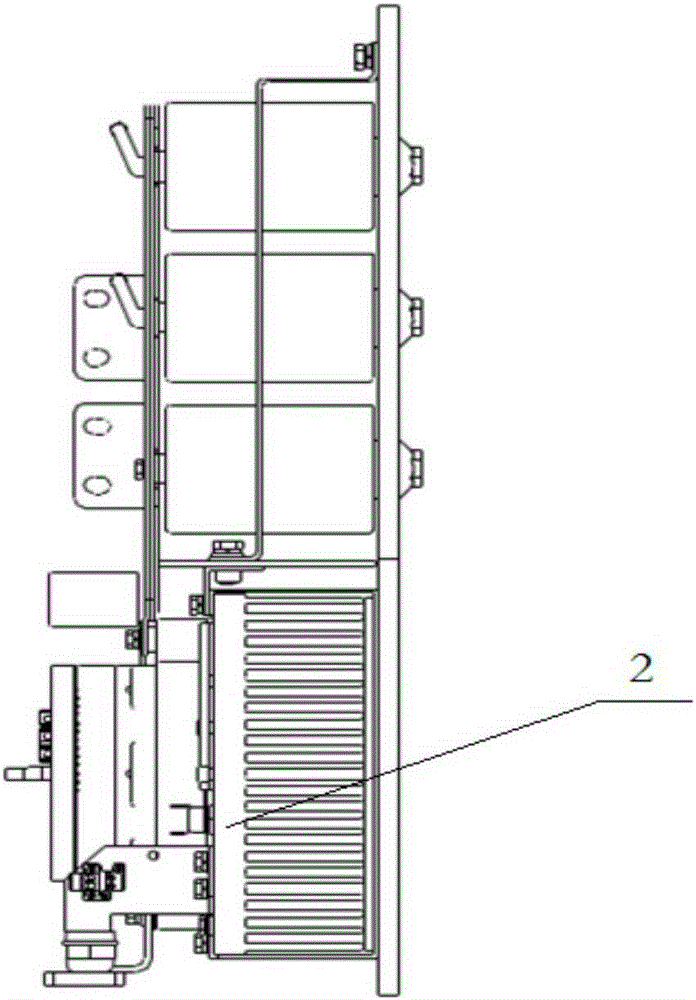

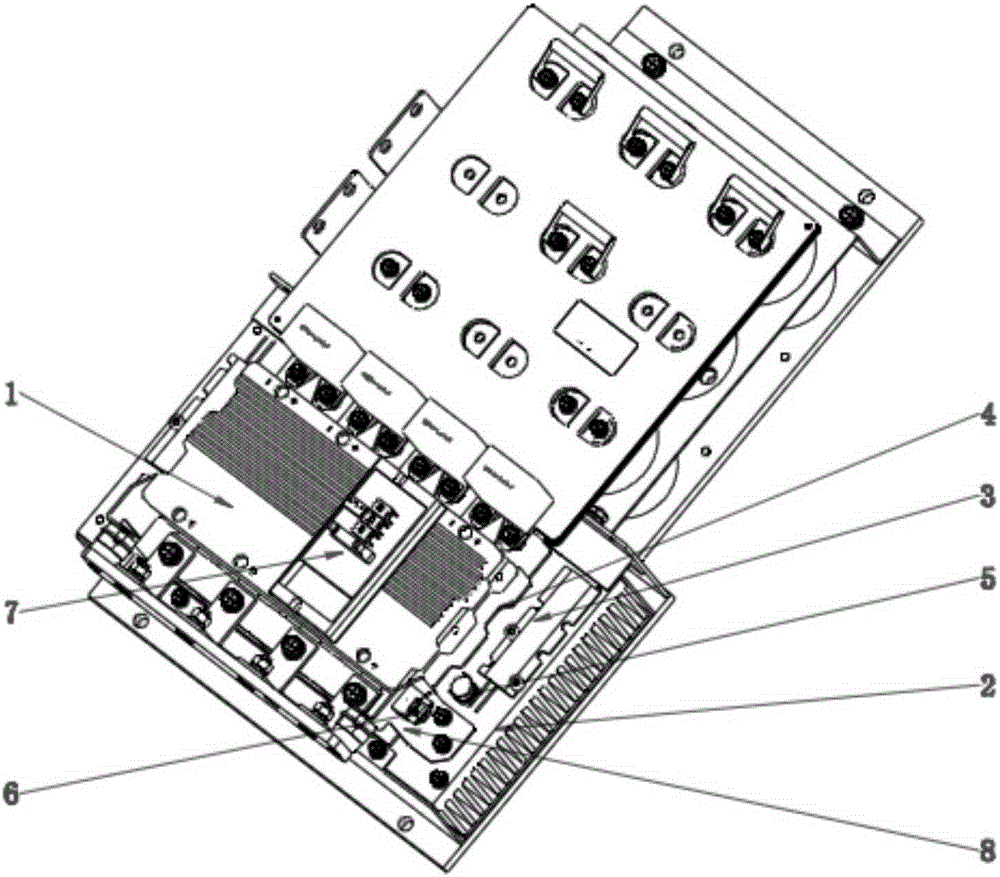

[0024] like Figures 1 to 3 As shown, a power module with moisture-proof and dehumidification function, including IGBT1, radiator 2, drive board 7, PTC heating resistor 3, sealant 4, temperature control switch 5, conformal paint and terminal 6, in the heat dissipation The IGBT1 is installed in the middle of the device 2, the sealant 4 is coated on the junction of the ceramic bottom plate of the IGBT1 and the radiator 2, and the PTC heating resistor 3 is installed on the radiator for cooling the IGBT1 2 and located on both sides of the IGBT1, the mounting surface of the PTC heating resistor 3 is coated with heat-conducting silicone grease, and the PTC heating resistor 3 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com