Telescopic tunnel steel arch frame

A technology for steel arches and tunnels, applied in the field of steel arches, can solve the problems of load release and adjustment of the surrounding rock that cannot be used, and achieve the effects of convenient operation and improved sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

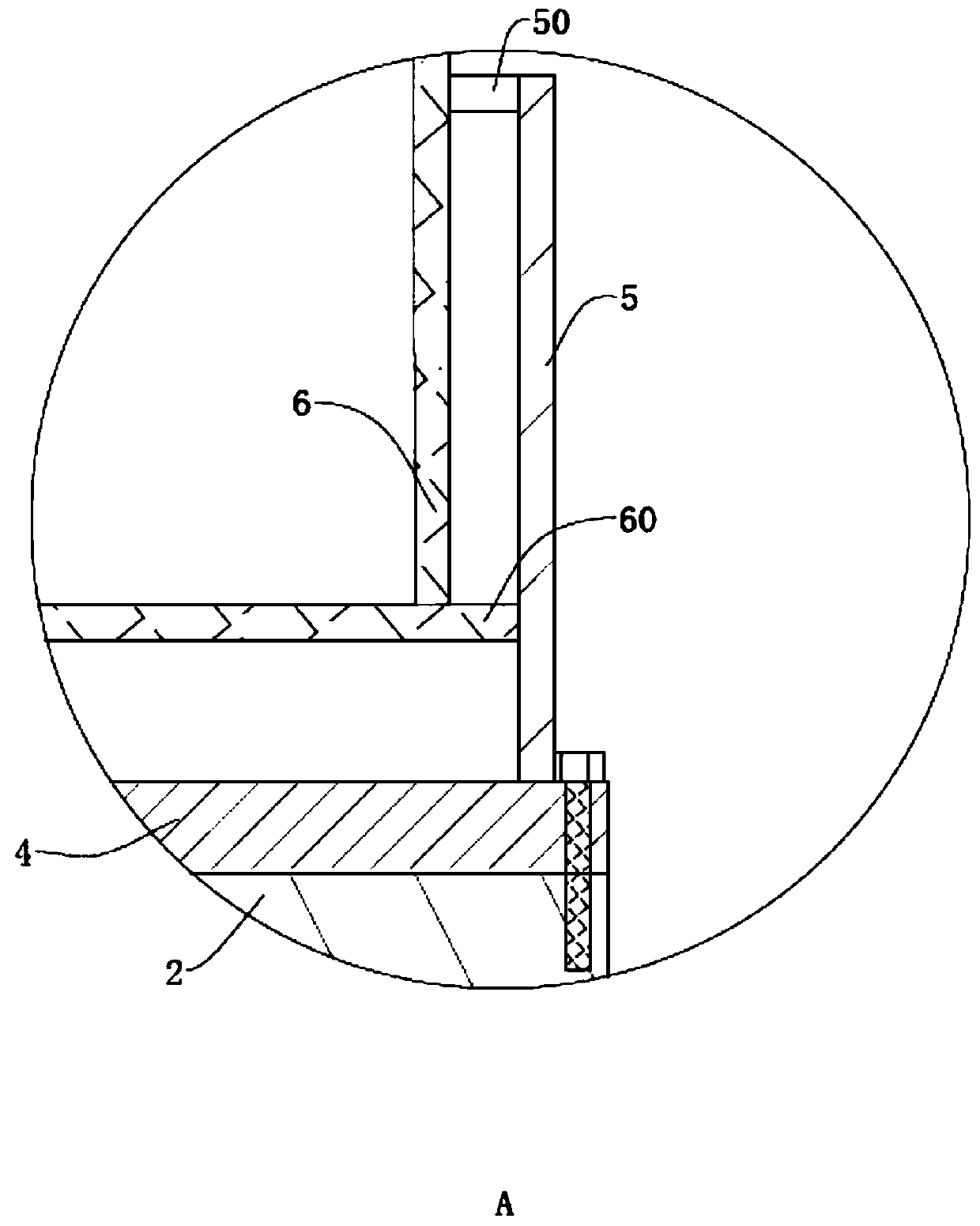

[0049] Embodiment 2, a telescopic tunnel steel arch frame, the difference between this embodiment and Embodiment 1 is: combining Figure 4 , the telescopic member includes a hydraulic cylinder 8 fixedly connected to the lower connection base plate 4, the output end of the hydraulic cylinder 8 is fixedly connected with a screw 80, and the screw 80 is threaded with an internally threaded pipe, and the end of the internally threaded pipe away from the hydraulic cylinder 8 is fixedly connected to the On connecting bottom plate 3.

[0050] The screw rod 80 is driven to rotate by the hydraulic oil cylinder 8, and the internally threaded tube and the screw rod 80 are relatively displaced by the screw rod 80, which is convenient for adjustment.

[0051] Working process and principle, by starting the hydraulic cylinder 8, the screw rod 80 and the inner threaded pipe can be adjusted up and down, and prestress application, deformation size control, load size control, etc. can be realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com