A compressed oxygen self-rescuer for easy escape in coal mine

An oxygen self-rescuer and self-rescuer technology, applied in the field of compressed oxygen self-rescuers, can solve the problems of restricting escape, unable to judge the escape path, unable to see clearly, etc., to achieve the effect of improving comfort and precious survival time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

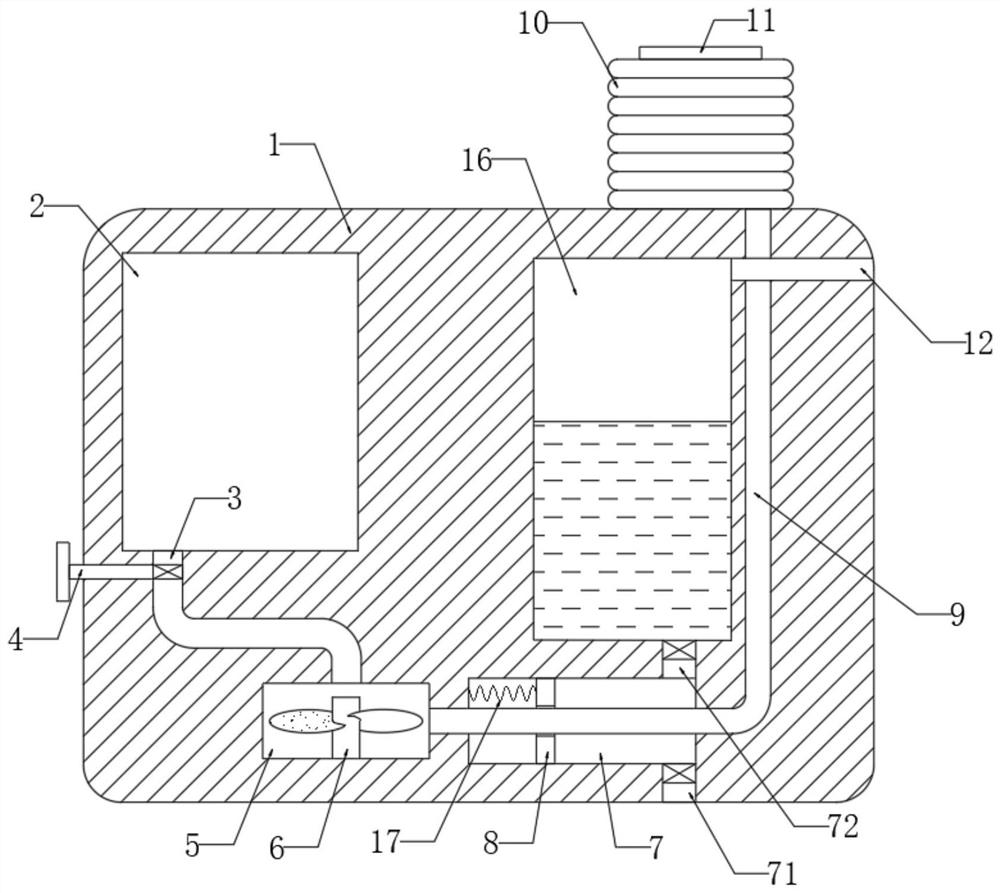

[0020] refer to figure 1 , a compressed oxygen self-rescuer that is easy to escape underground in a coal mine, comprising a self-rescuer body 1, an oxygen storage chamber 2 is opened on the side wall of the self-rescuer body 1, an airbag 10 is fixedly connected to the upper end of the self-rescuer body 1, and the upper end of the airbag 10 is installed There is a breathing mask 11 communicating with it.

[0021] The side wall of the self-rescuer body 1 is provided with a circular groove 5, the inner bottom of the circular groove 5 is rotatably connected with a centrifugal fan 6, and an air intake pipe 3 is communicated between the circular groove 5 and the oxygen storage chamber 2, and the air intake pipe 3 A control valve 4 is installed, an air outlet pipe 9 is communicated between the circular groove 5 and the air bag 10, and a bar-shaped groove 7 is opened on the side wall of the self-rescuer body 1, and an iron sliding plug 8 is sealed and slidably connected in the bar-sha...

Embodiment 2

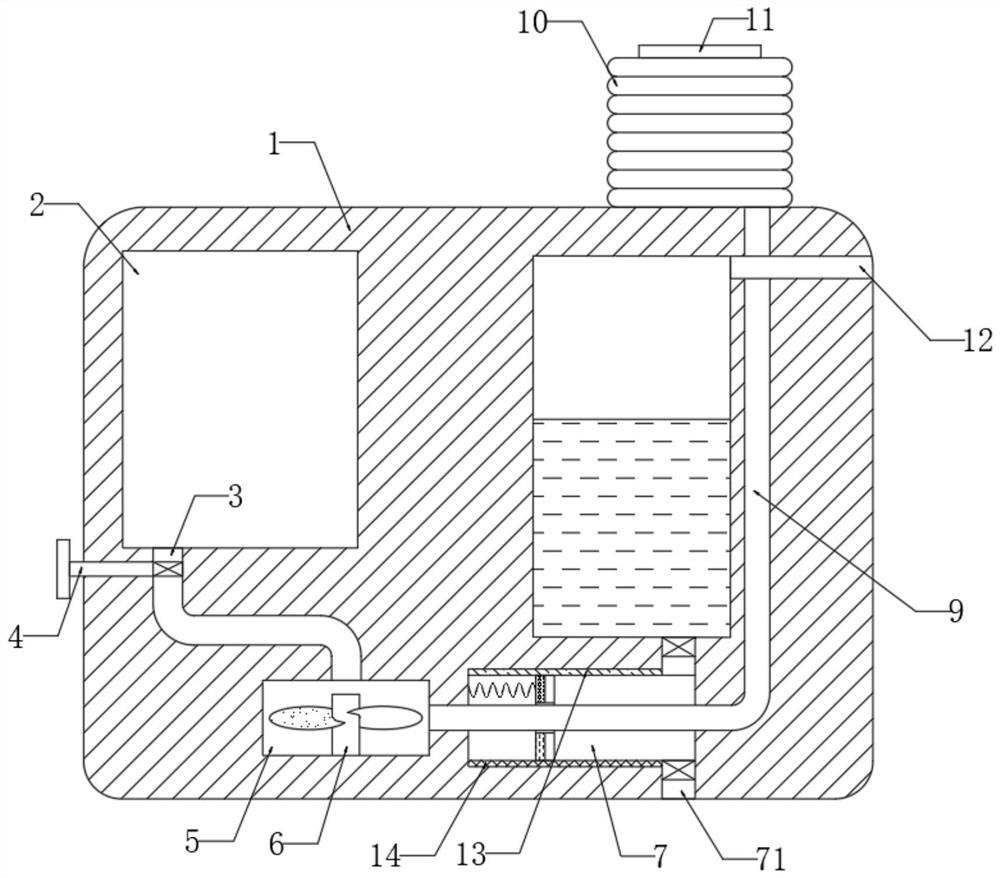

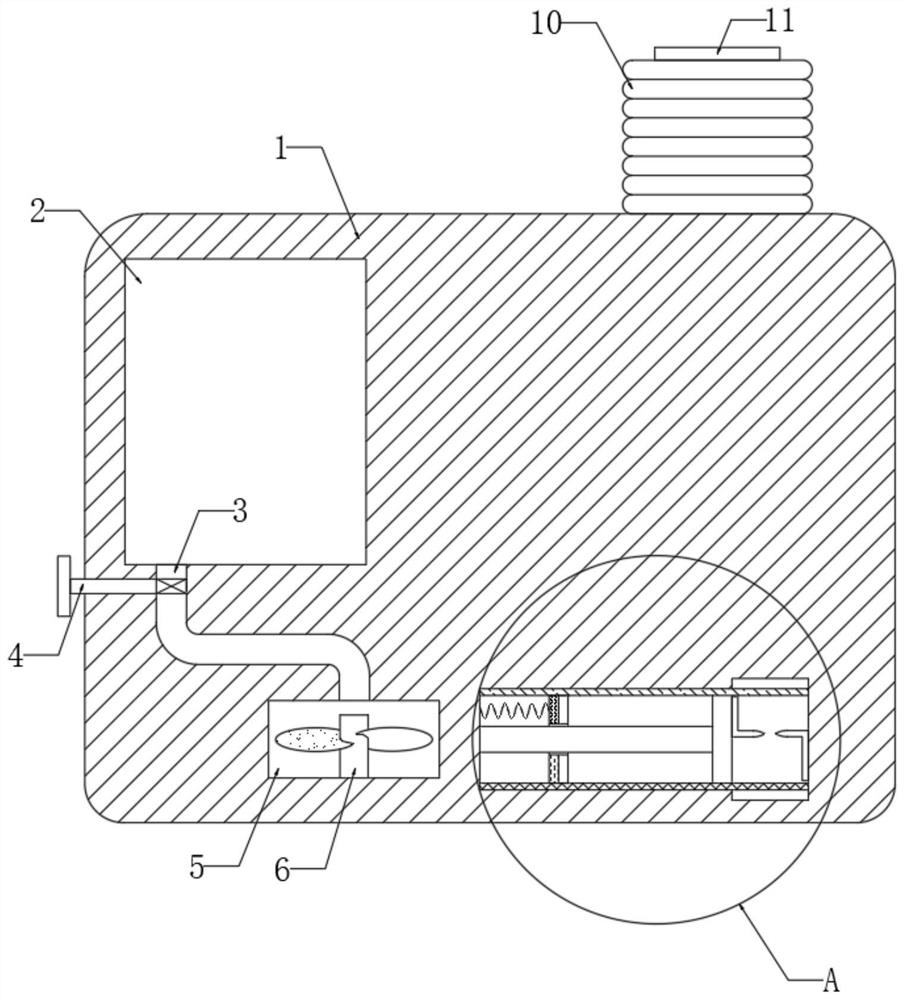

[0031] refer to Figure 2-4 , the difference from the first embodiment is that the inner top of the strip groove 7 is fixedly connected with a rubber plate 13, the inner bottom of the strip groove 7 is fixedly connected with a glass plate 14, and the side walls of the slide plug 8 are fixedly connected from top to bottom. There is a fur layer 82 and a silk layer 81 , and a hollow cavity 15 is opened on the side wall of the self-rescuer body 1 .

[0032] It should be noted that the fur layer 82 and the silk layer 81 are only provided on a part of the left side of the sliding plug 8 , for details, please refer to the manufacture Figure 4 , so that the fur layer 82 and the silk layer 81 can be rubbed against the rubber plate 13 and the glass plate 14 , and the side wall of the slide plug 8 and the inner wall of the strip groove 7 have good air tightness.

[0033] And the rubber plate 13 and the glass plate 14 both extend into the hollow cavity 15 , the two opposite inner walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com