A double-valve type fuel oil radiator for lubricating oil filter

An oil-burning and valve-type technology, which is applied in the directions of engine lubrication, turbine/propulsion device lubrication, turbine/propulsion device cooling, etc., can solve the difficulty of engine maintenance, system oil loss, and cycle oil waste To reduce the difficulty of daily maintenance and scientific research management, avoid disassembly and connection, and avoid the loss of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

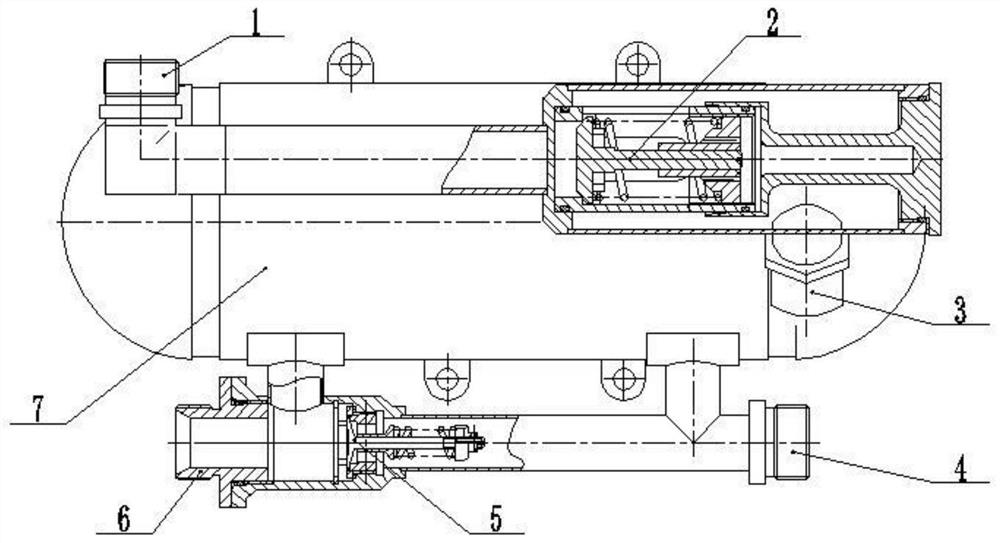

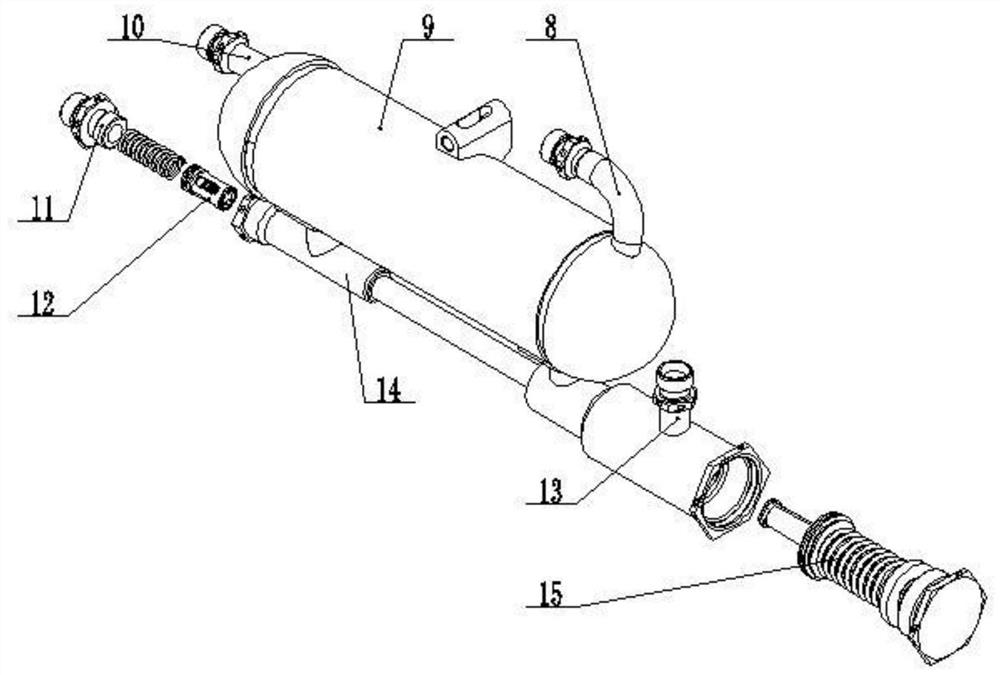

[0039] Such as Figure 4 , Image 6 As shown, the fuel oil radiator b9 may be blocked by foreign objects during use. There is a lubricating oil safety valve 12 at the lubricating oil inlet. If the device b9 is blocked, the lubricating oil will enter the lubricating oil control assembly 14 from the lubricating oil inlet b11, directly open the lubricating oil safety valve 12, and then flow into the next component.

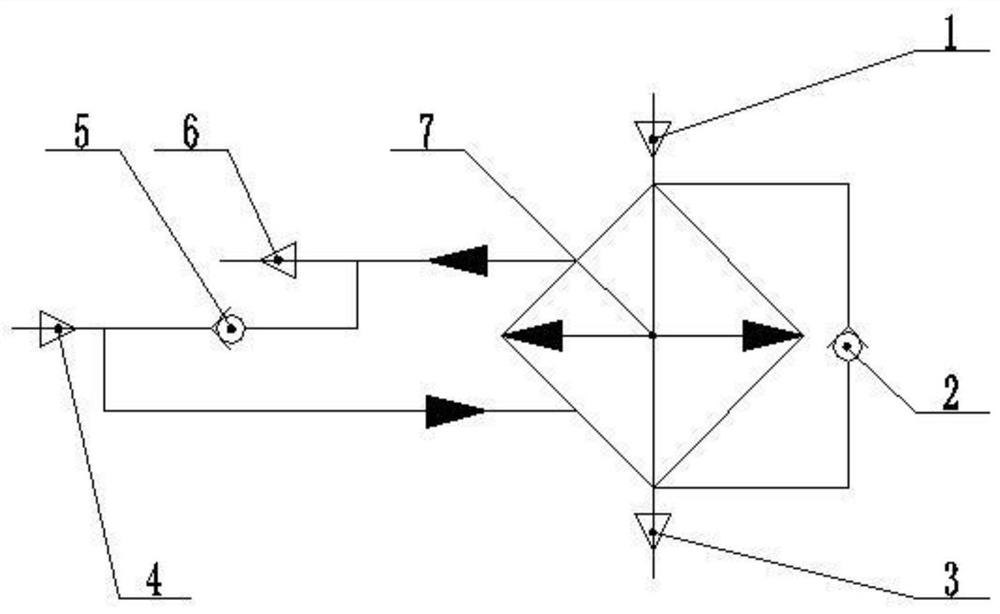

[0040] At the outlet of the lubricating oil control assembly 14, there is a lubricating oil filter double valve assembly 15. Adjust the lubricating oil filter safety valve adjustment seat 1510 and the lubricating oil blocking cover 1512 to make the anti-siphon valve 1504 reach the set opening pressure. Below the set lubricating oil pressure, the anti-siphon safety valve 1504 is in a normally closed state. When the lubricating oil pressure reaches the set pressure, the anti-siphon safety valve 1504 opens and the lubricating oil flows out normally; when the engine sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com