Anti-damage bionic manipulator for mushroom picking

An anti-damage and manipulator technology, applied in mushroom cultivation, application, gardening, etc., can solve the problems of high labor intensity and immature technology in picking, and achieve the effects of damage-free picking, quality assurance, and high picking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

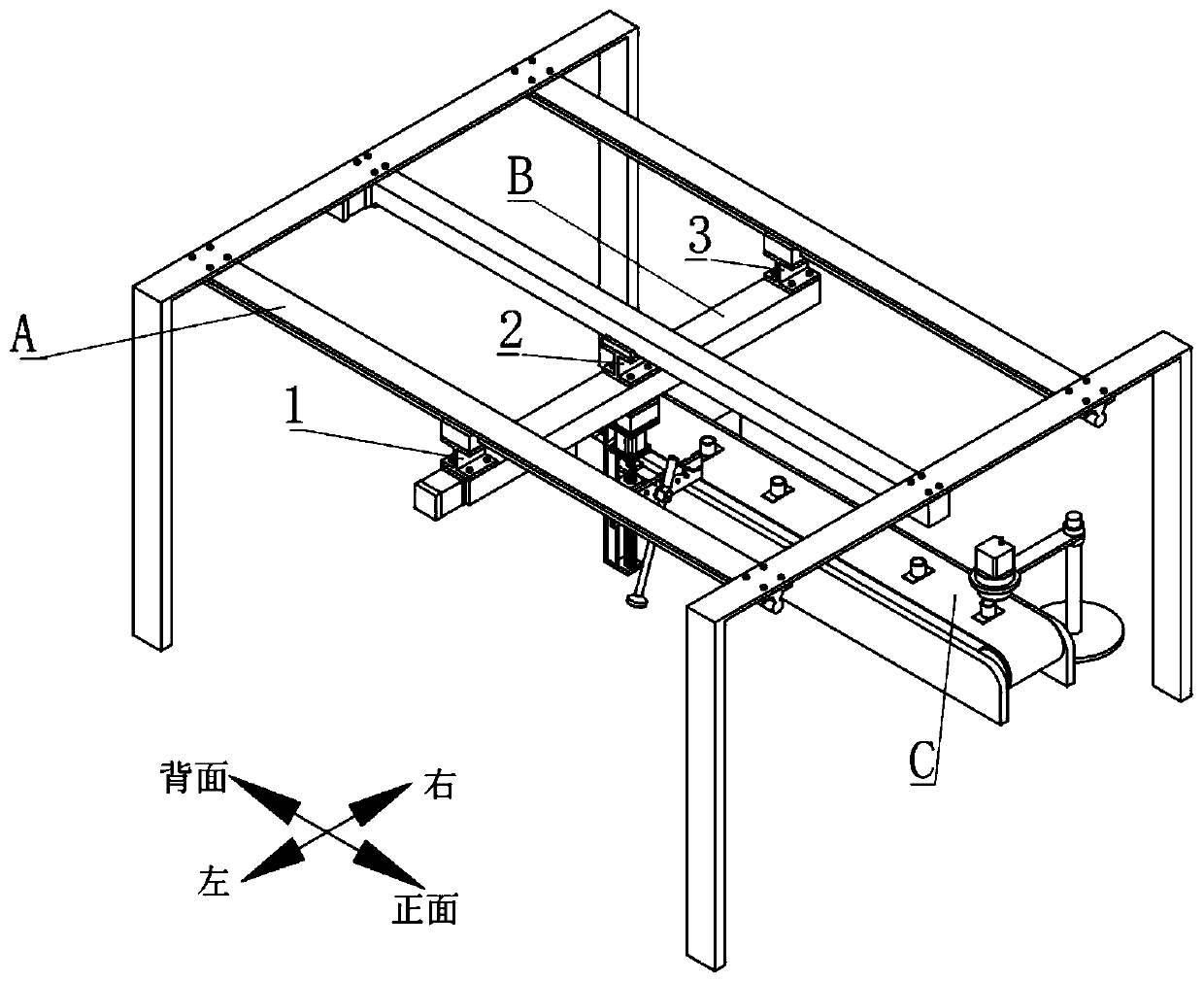

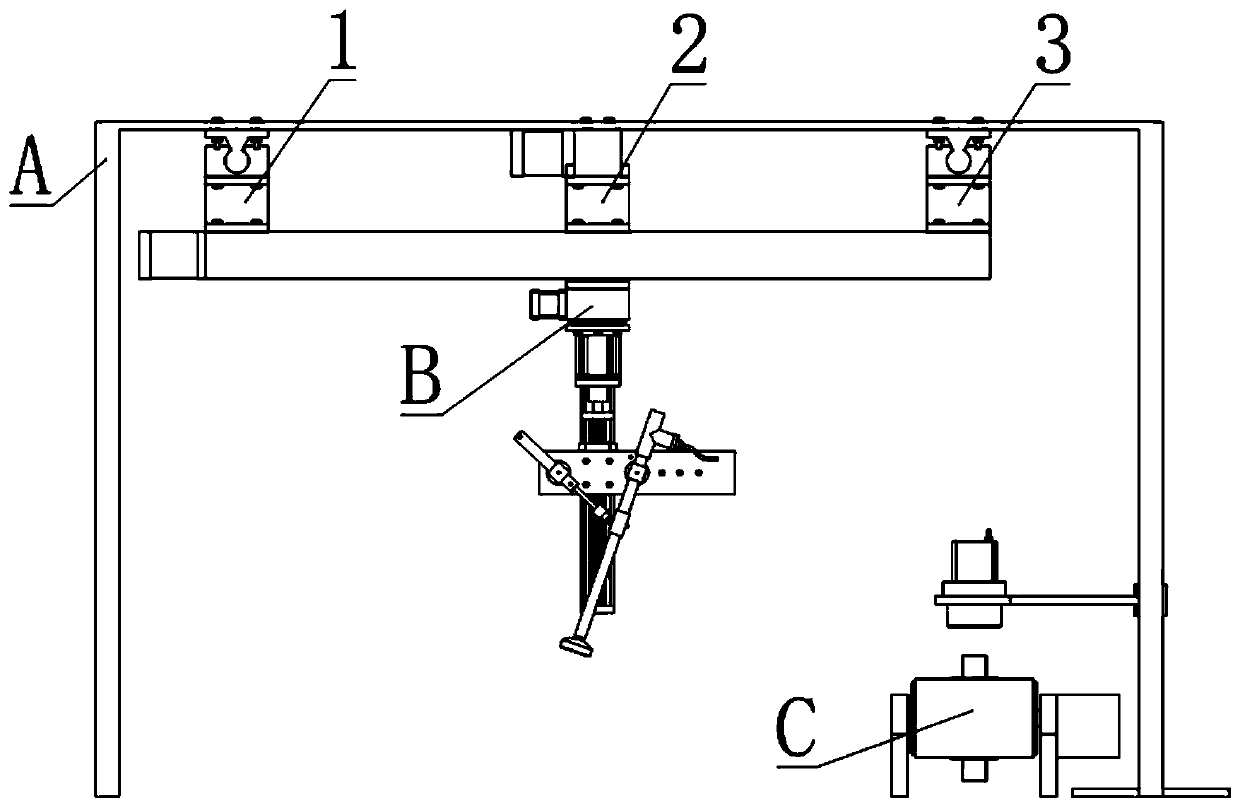

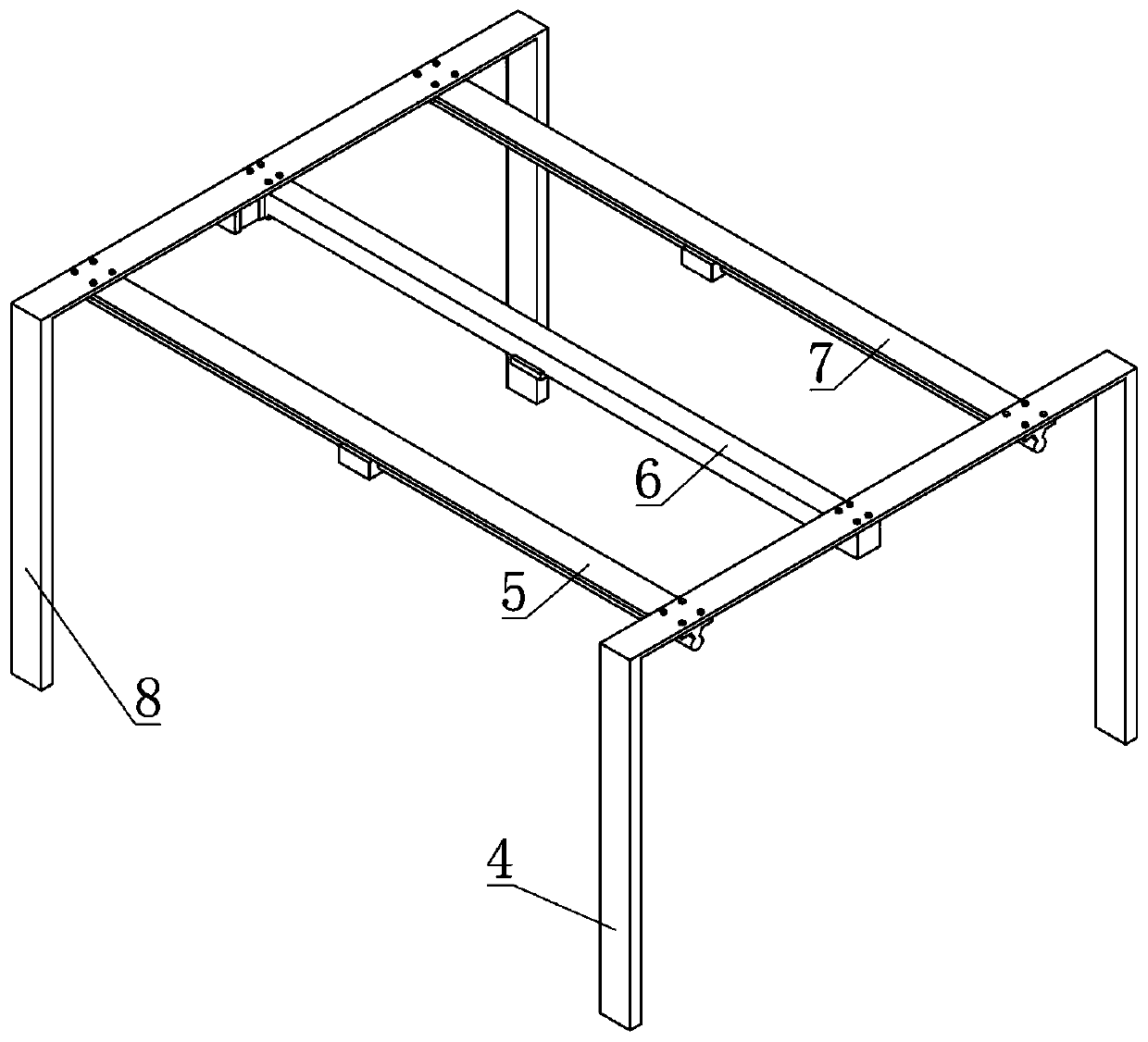

[0036] like figure 1 , figure 2 , image 3 As shown, an anti-damage bionic manipulator for mushroom picking in the present invention is composed of a forward and backward moving part A, a vertical, left, right and posture adjustment part B, and a transmission and information recording part C. The up, down, left, right, and attitude adjustment part B is slidably connected with the front and rear moving part A through a sliding connection assembly, so that the up, down, left, right, and attitude adjustment part B can slide forward and backward along the front and rear moving part A; To work, the mushrooms are picked and transported to the transmission and information recording unit C; the transmission and information recording unit C is installed on the ground, located on the right side of the whole mechanism, and the transmission and information recording unit C sprays in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com