Convenient treading type yellow peach pit removing equipment and using method thereof

A stepping-type, nuclear equipment technology, applied in fruit pitting devices, applications, food science, etc., can solve the problems of lowering the production quality of yellow peaches, reducing economic benefits, and easily damaging peach flesh, so as to increase practicability and increase economy benefit, the effect of increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

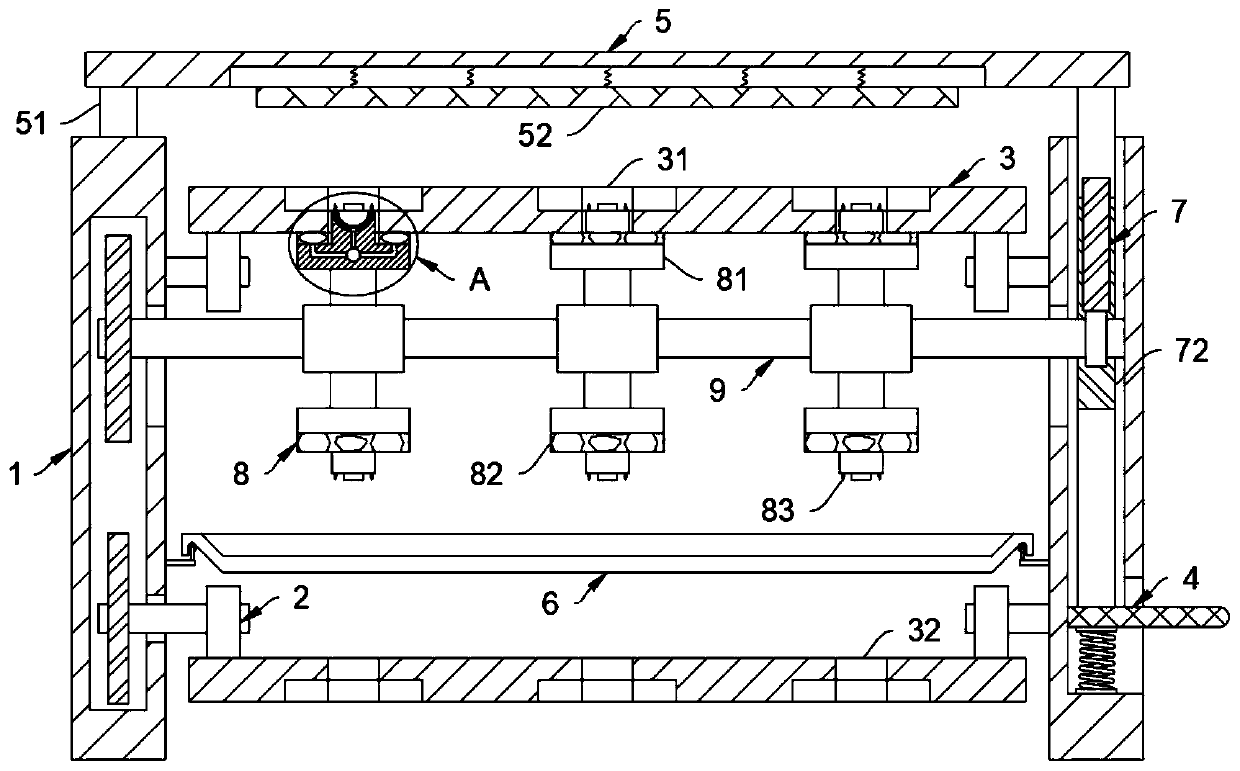

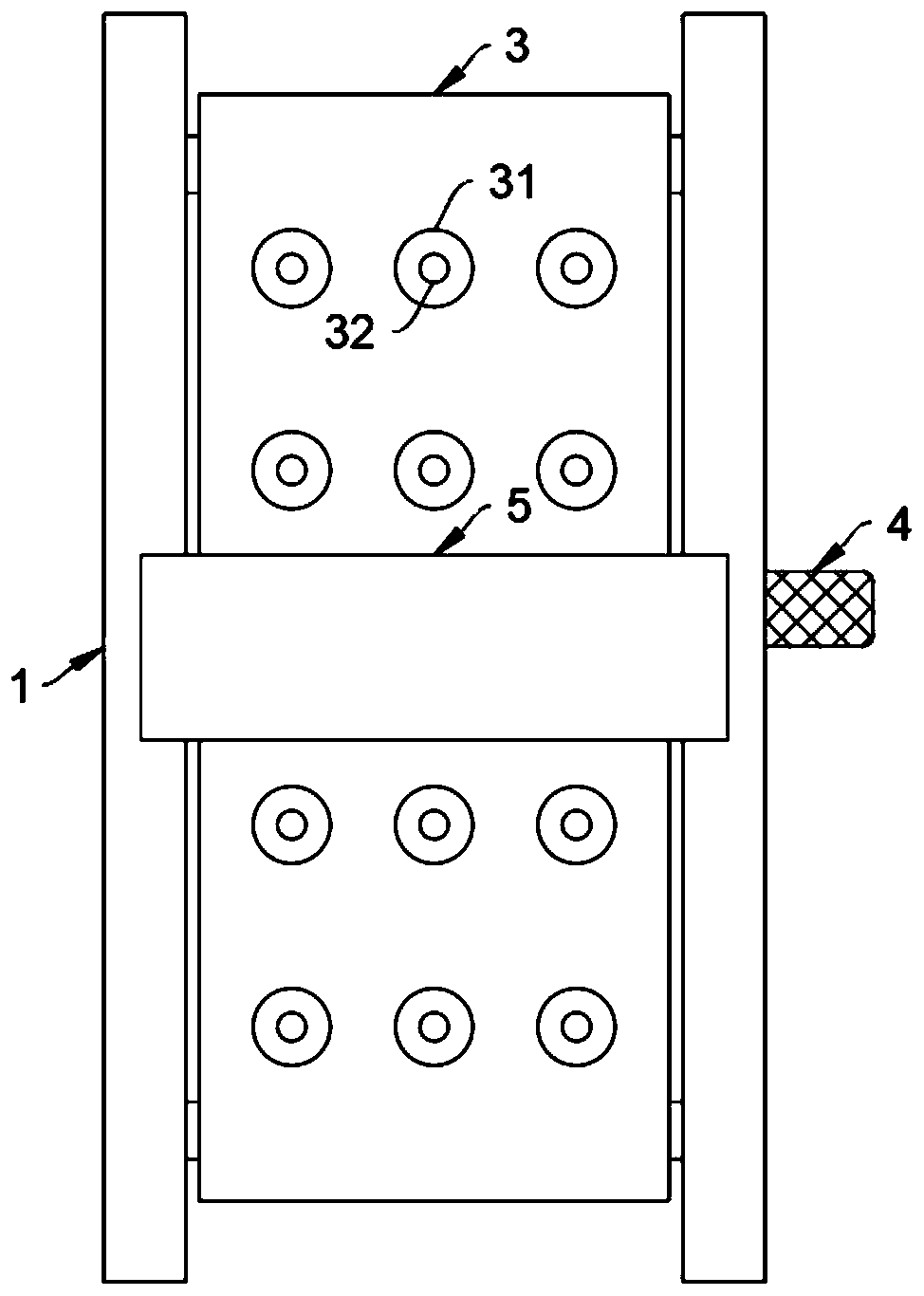

[0035] Such as Figure 1-4 As shown, a convenient stepping type yellow peach pitting equipment and its use method include a support 1, and the support 1 is connected to the conveyor belt 3 through the rotation of the idler 2. It should be noted that the support 1 and the conveyor belt 3 Adjust the working length according to the use requirements, which is convenient for the device to carry out the denuclearization work. The conveyor belt 3 adopts a trapezoidal conveying method, which is convenient for the connection and use of the denuclearization mechanism 8. The end of the conveyor belt 3 close to the idler 2 is meshed through the toothed structure. The rollers 2 are rotatably connected to the support 1 through bearings, and one set of idler rollers 2 is connected with the driving mechanism to control the stop and start of the conveyor belt 3 .

[0036] Concretely, the conveyer belt 3 is provided with a plurality of sets of placement grooves 31, and the placement grooves 31 ...

Embodiment 2

[0048] Such as Figure 5 Shown, the difference between this embodiment and embodiment 1 is:

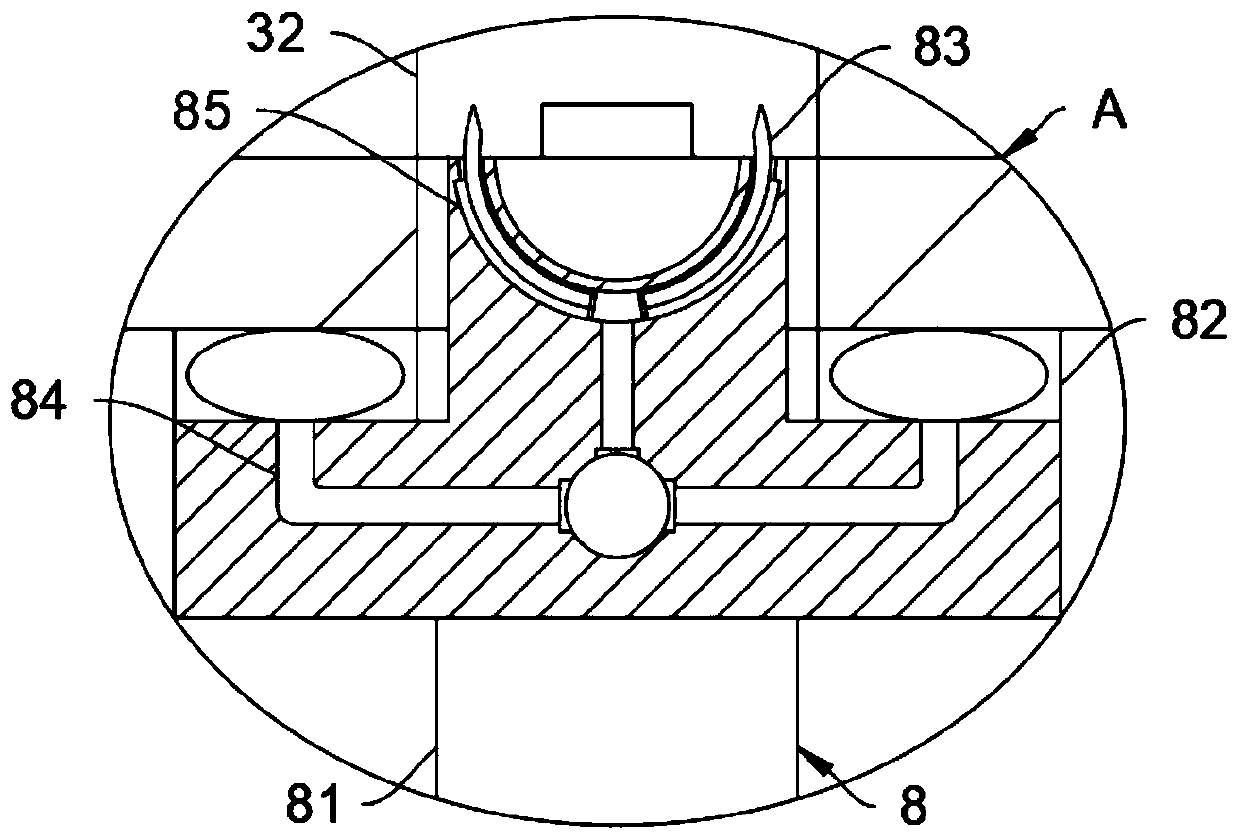

[0049] The turret 81 includes a positioning sleeve 811 and a core removal part 812. The positioning sleeve 811 is symmetrically provided with a sleeve 813, and the core removal part 812 is slidably connected with the sleeve 813 through a telescopic rod 814. It is worth mentioning that the core removal blade 83 is During the process of pitting work, since the walnut itself carries part of the peach flesh, it is easy to stick to the pit groove. By sliding the telescopic rod 814 and the sleeve 813 on the turret 81, the pitting part 812 can be rotated and dropped. Under the action of its own gravity, it will shake and shake the peach pits in the pit to improve the pitting effect of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com