Horizontal centrifugal patting kernel removal device and production line

A kind of nuclear device and horizontal technology, which is applied in the field of betel nut removal device and production line, can solve the problems of high operating cost, large damage to the surface of betel nut, and high damage rate of betel nut edge, so as to improve the effect of nuclear removal, reduce the damage of betel nut, Reduce the effect of slapping damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

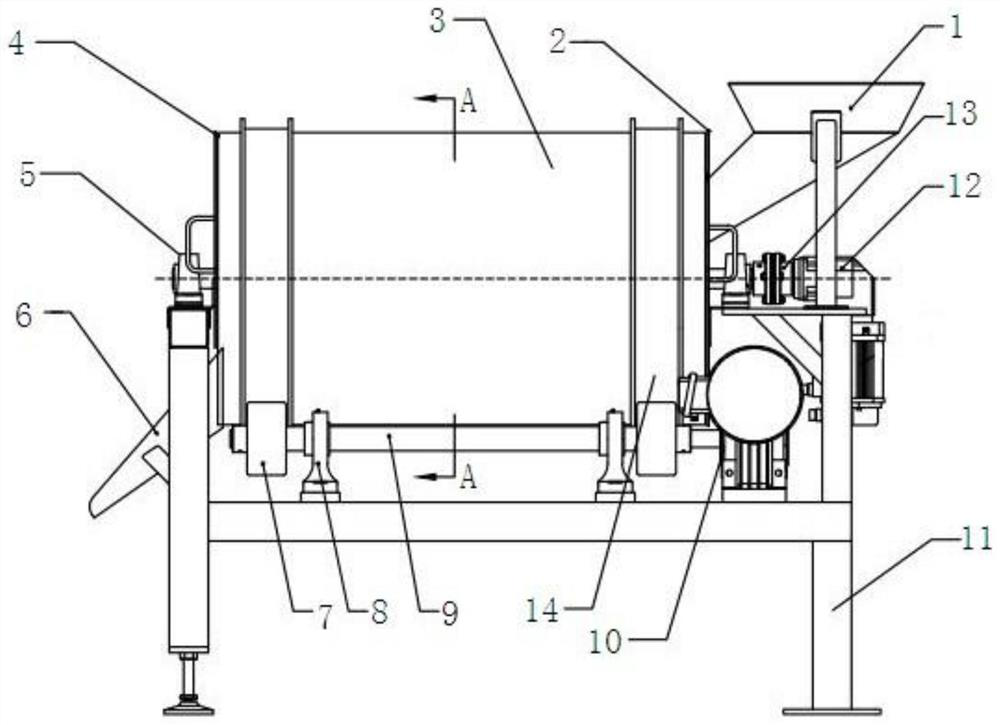

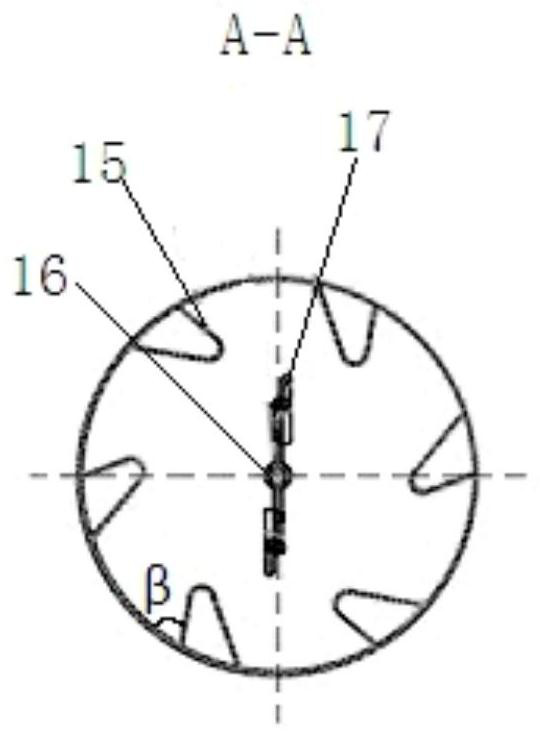

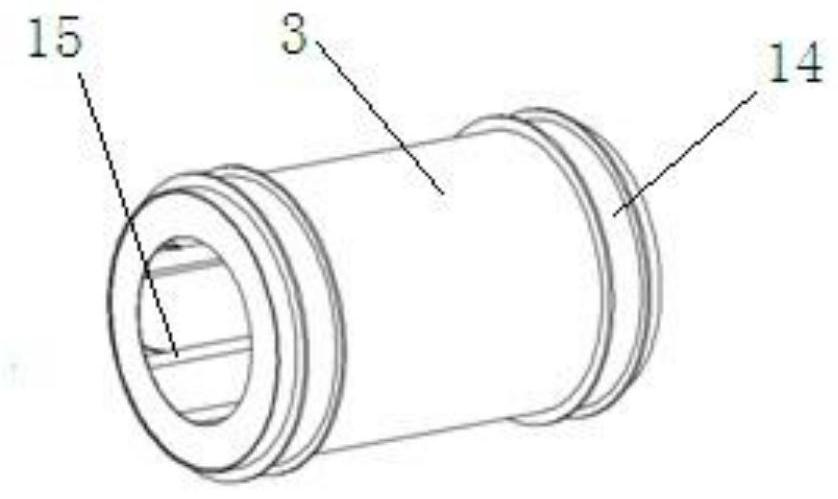

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, be the inventor's first generation machine, a kind of horizontal centrifugal beating nuclear device, a kind of horizontal centrifugal beating nuclear device, comprise frame 11, be placed on the cylinder 3 above frame 11 and run through The central rotating shaft 16 that is provided with in the cylinder 3 also includes a plurality of tape troughs 15 that are located on the inner wall of the cylinder 3 and a beating plate 17 that is located on the central rotating shaft 16; A bent plate at a certain angle, the beating plate 17 is a plate-shaped body, and the length direction of the beating plate 17 is arranged parallel to the axial direction of the central rotating shaft 16 .

[0049] Cylinder 3 is made of 304 stainless steel, with a length of 1 meter. The inner surface is smooth and clean, without edges and sharp corners. All sharp corners are made into arc transitions, which can reduce the damage of betel nuts ...

Embodiment 2

[0059] Such as Image 6 Shown, be the inventor's second-generation machine, a kind of horizontal centrifugal beating denucleating device, concrete structure is the same as embodiment 1, and difference is that described belt trough 15 is made up of three parts along the lengthwise direction, from feeding From the end to the discharge end, there are feeding guide plate 22 , belt material plate 24 and discharge guide plate 23 in sequence.

[0060] The feed guide plate 22 is arc-shaped, and the feed guide plate 22 forms an angle θ of 100°-165° with the belt material plate 24. Degree-255 degree included angle θ', this design makes the betel nut be cushioned when feeding and discharging, reducing the damage caused by the impact during the falling process.

Embodiment 3

[0062] Such as Figure 7-9 As shown, it is the inventor's third-generation machine, a horizontal centrifugal beating and denucleating device, which includes a cylinder 3 and a central rotating shaft 16 that runs through the cylinder 3, and also includes a cylinder that is located on the inner wall of the cylinder 3. A plurality of tape troughs 15, and the beating plate 17 that is located on the central rotating shaft 16; the length direction of the tape plate 24 is arranged parallel to the axis of the cylinder or at an acute angle; the beating plate 17 is arranged along the length direction of plates.

[0063] The belt trough 15 is composed of three parts along the length direction, and from the feed end to the discharge end, it is a feed guide plate 22, a belt material plate 24 and a discharge guide plate 23. The feed guide plate 22 is arc-shaped, and The material guide plate 22 forms an included angle θ of 100°-165° with the belt material plate 24, the discharge guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com