Destroying device for used syringes

A technology for destroying devices and syringes, which is applied to hypodermic injection devices, devices introduced into the body, waste collection and transfer, etc. It can solve the problems of low work efficiency, troublesome operation, inconvenient collection, etc., and achieve high work efficiency and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

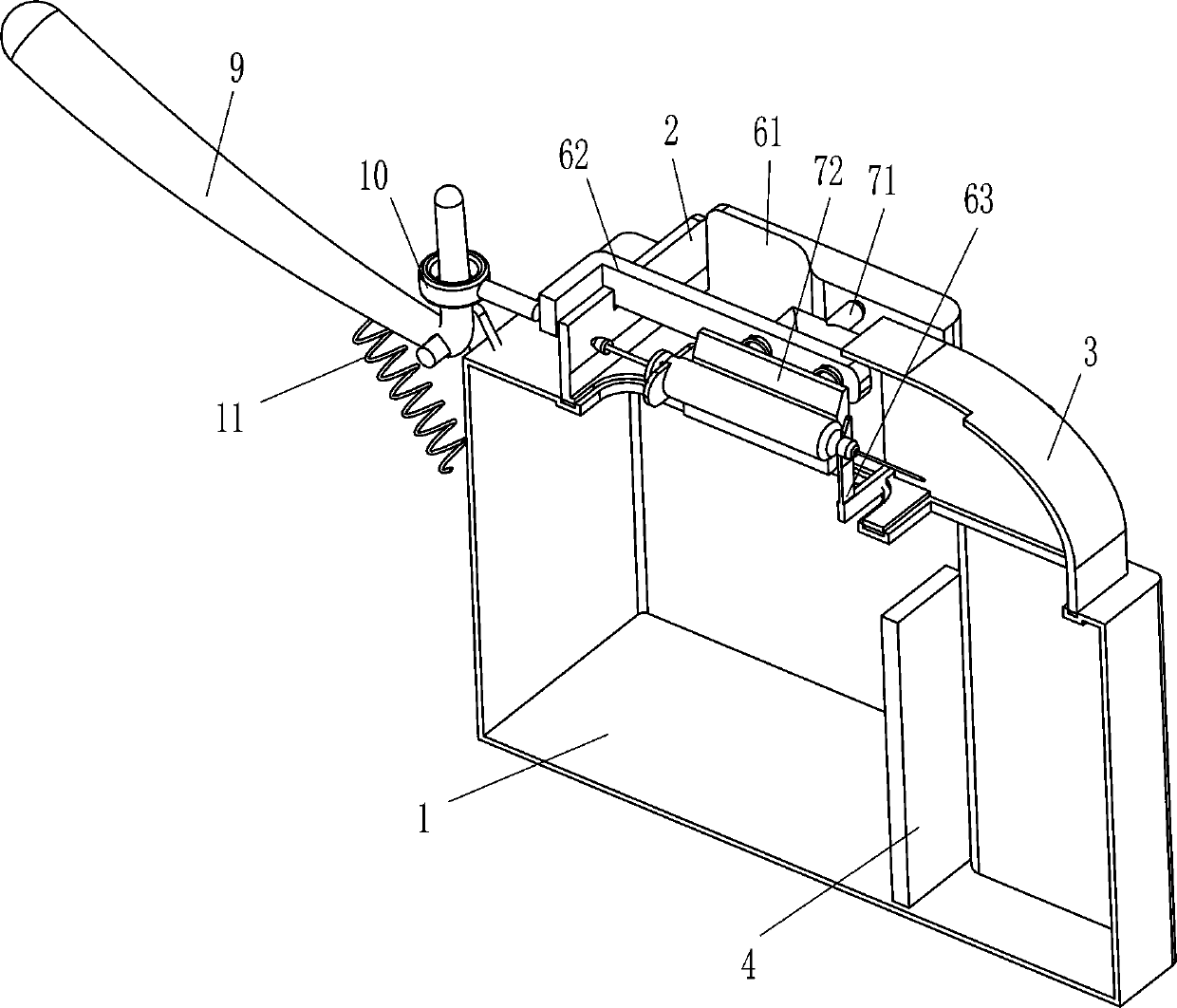

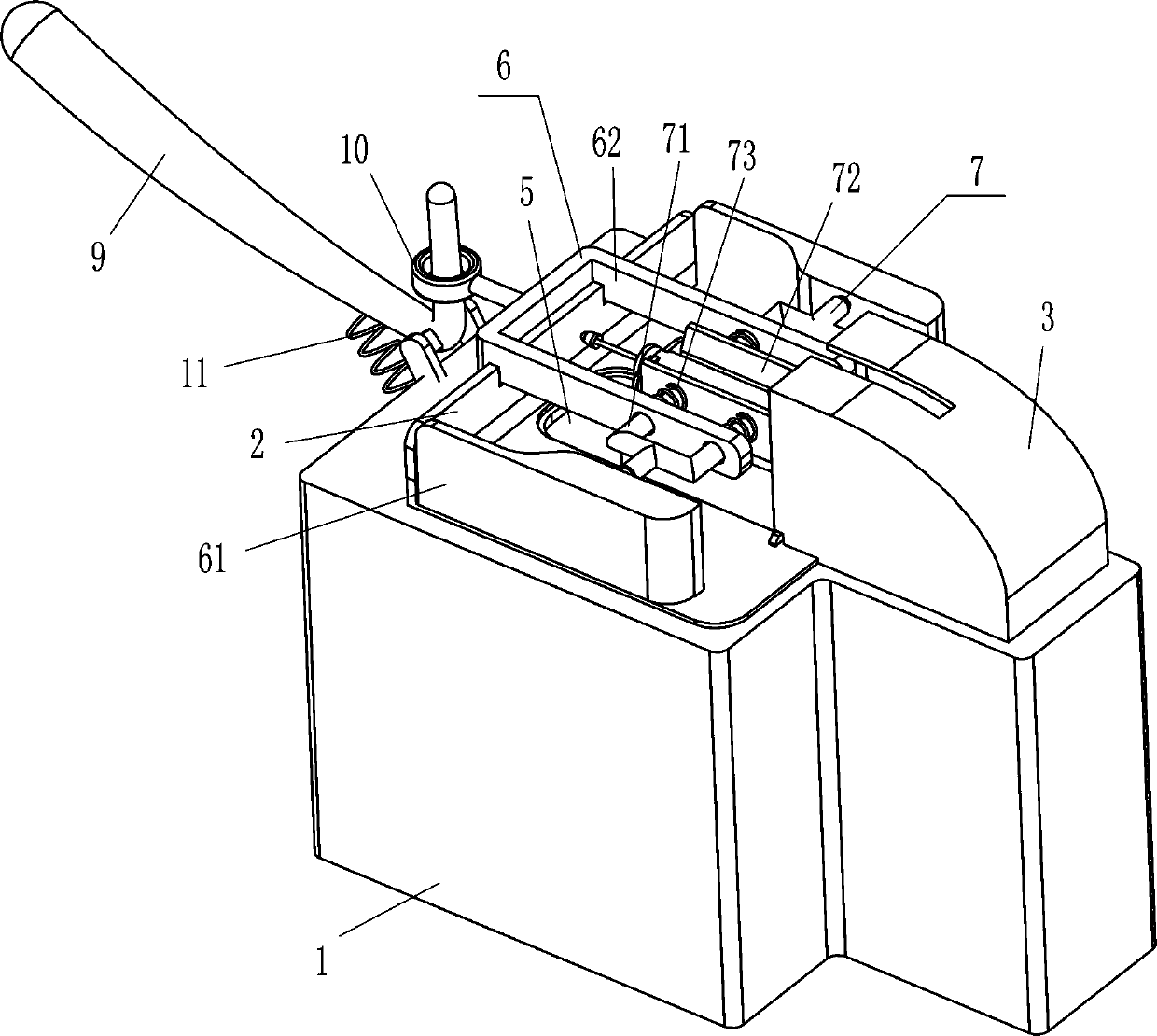

[0021] see figure 1 and figure 2 , a device for destroying syringes after use, including a box body 1, an L-shaped clamping plate 2, a housing 3, a partition plate 4, a driving mechanism 6 and a pressing mechanism 7, and the outer top of the box body 1 is clamped with an L-shaped clamping plate 2. A housing 3 is firmly connected to the middle of the inner bottom right side of the L-shaped card board 2, and the housing 3 is snap-connected with the outer top right side of the box body 1, and a partition plate 4 is fixedly connected to the right middle of the inner bottom of the box body 1, Type clamp 2 is provided with drive mechanism 6, and drive mechanism 6 is provided with compression mechanism 7 that can make syringe place, and compression mechanism 7 cooperates with drive mechanism 6, and L-shaped clamp 2 inner bottom middle is opened to make needle The through hole 5 through which the barrel passes, and the through hole 5 communicates with the inside of the box body 1 . ...

Embodiment 2

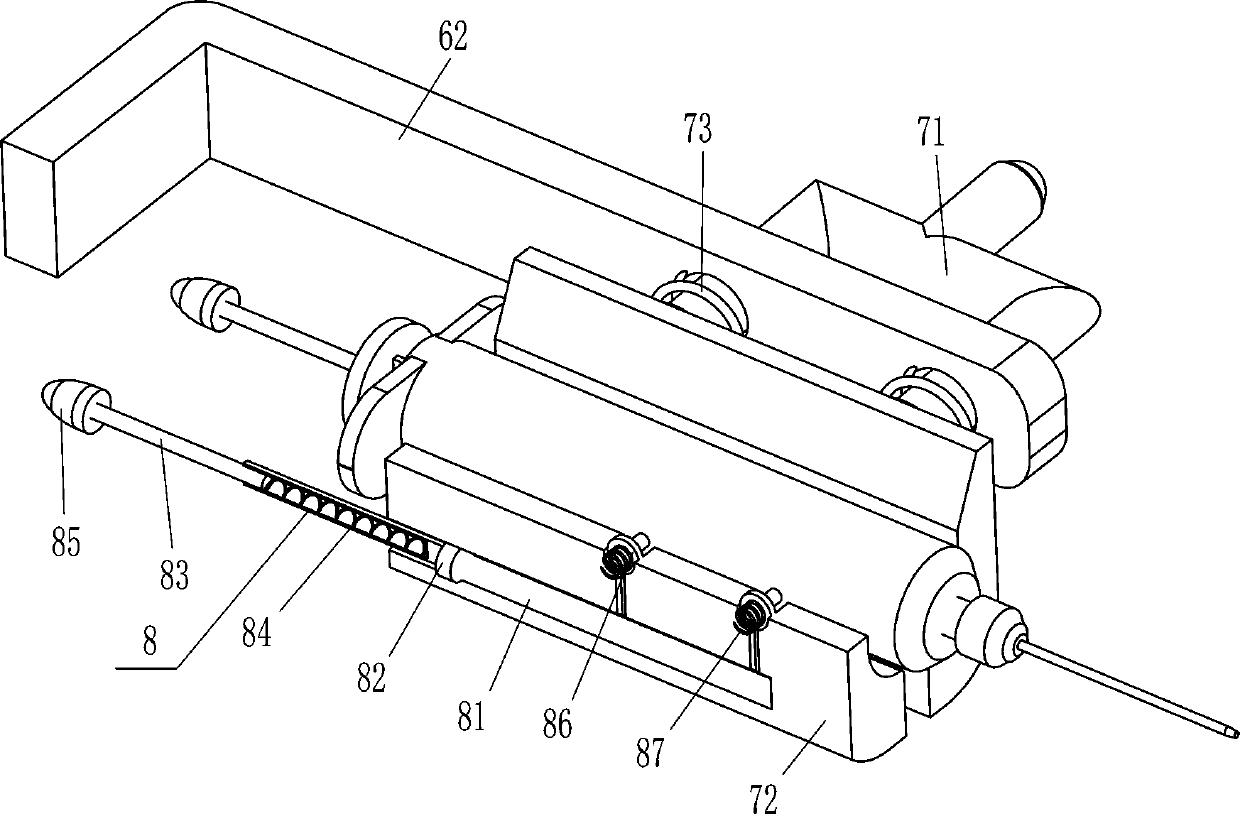

[0028] see image 3 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a destroying mechanism 8 is also included, and the destroying mechanism 8 includes a piston sleeve 82, a movable rod 83, a second spring 84, a ball seat 85, a piston Taper head 86 and the 3rd spring 87, special-shaped pressure plate 72 bottoms of front and back sides have special-shaped groove 81, and special-shaped groove 81 bottom left sliding type is provided with piston sleeve 82, and piston sleeve 82 inner sliding type is provided with Movable bar 83, movable bar 83 left ends are affixed with rolling ball seat 85, and rolling ball seat 85 cooperates with L-shaped clamping plate 2, and second spring 84 is connected between movable bar 83 right-hand sides and the inner right side of piston sleeve 82, The left and right sides of special-shaped groove 81 top are slidingly provided with the piston cone 86 that can destroy the syringe, and the third spring 87 is co...

Embodiment 3

[0031] see figure 1 and figure 2 The main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, it also includes an L-shaped pull rod 9, a hanging ring 10 and a fourth spring 11, and the middle of the upper left side surface of the outer box body 1 is hinged with a L-shaped pull rod 9, a fourth spring 11 is connected between the right side of the inner bottom of the L-shaped pull rod 9 and the top of the outer left side of the box body 1, and a hanging ring 10 is fixedly connected to the middle of the outer left side of the u-shaped plate 62, and the hanging ring 10 Be enclosed within L-shaped tie rod 9 tops and cooperate with it.

[0032] After the syringe is placed, the left part of the L-shaped pull rod 9 is pulled to swing downward, the fourth spring 11 is compressed, the left part of the L-shaped pull rod 9 swings downward to make the upper part swing to the left, and the upper part of the L-shaped pull rod 9 swings to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com