Pipeline cleaning tool and pipeline cleaning process

A technology for cleaners and pipelines, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cloth stuck in the pipeline, pipeline cleaning is not in place, etc., so that it is not easy to stick , Guaranteed cleanliness and high industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

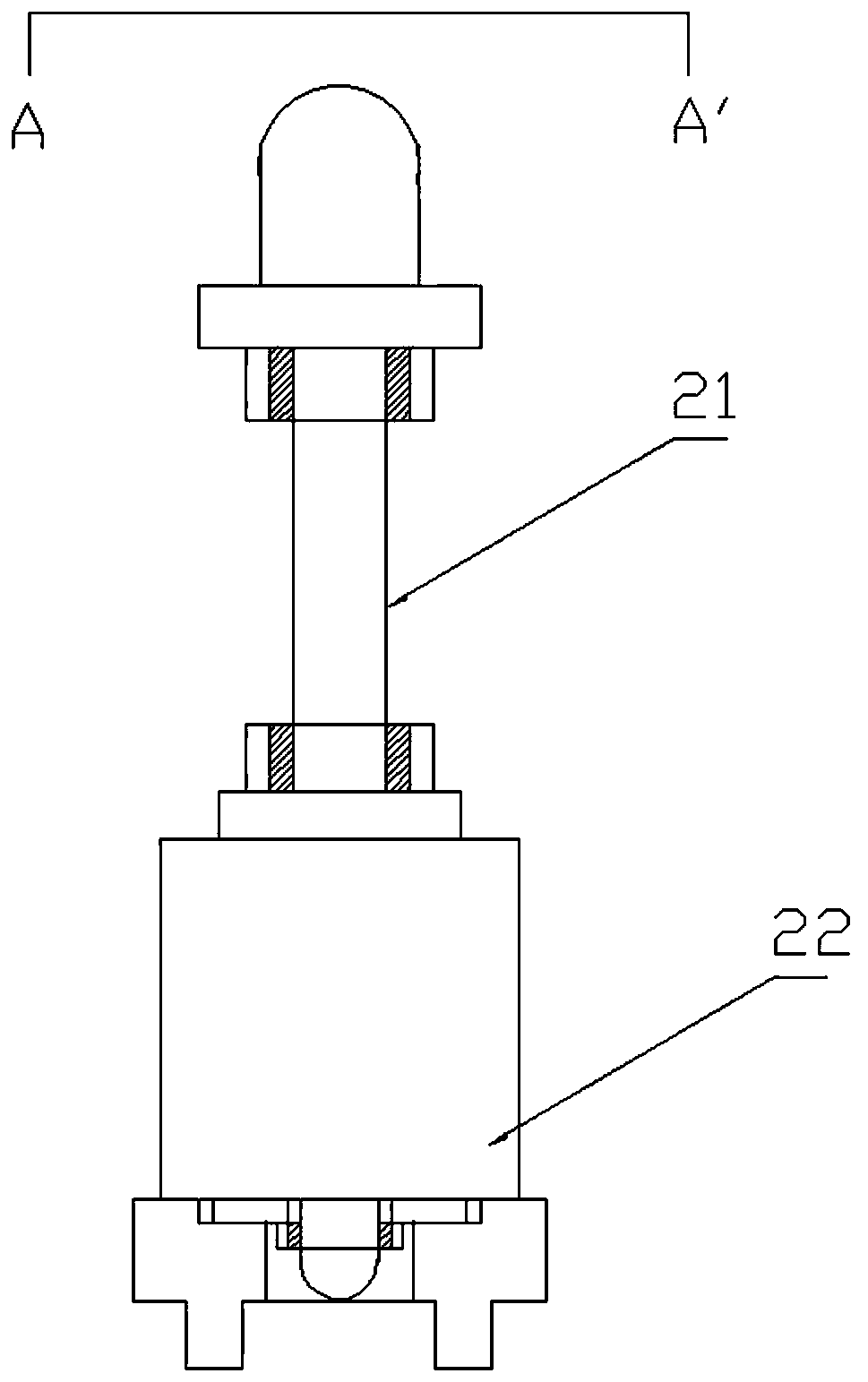

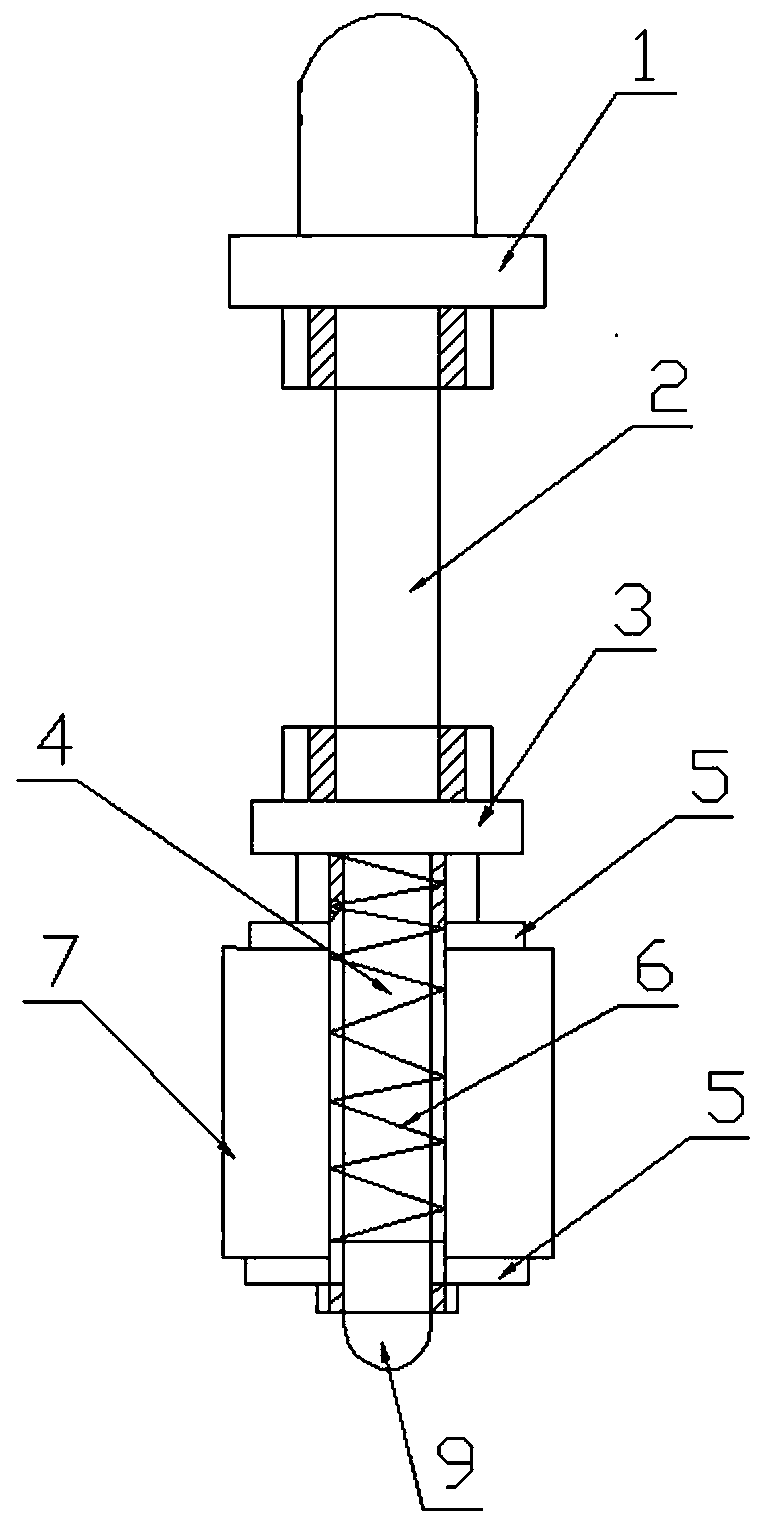

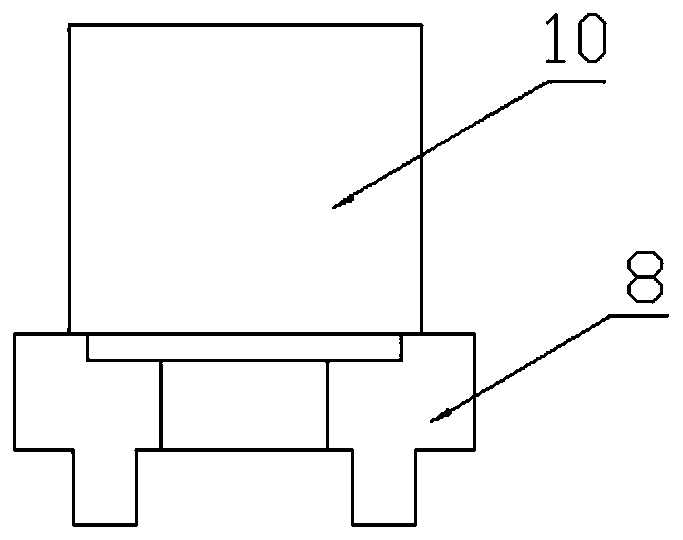

[0043] Such as Figure 1 ~ Figure 4 As shown, this embodiment provides a pipeline cleaning tool, which includes a decontamination device 21 and a cleaning storage device 22. The decontamination device 21 includes a handle 1, a universal pipe 2, a connecting screw 4 and a sponge 7. The handle 1 is located in the universal To the top of the pipe 2, the connecting screw 4 is located below the universal pipe 2, and the universal pipe 2 is connected to the handle 1 and the connecting screw 4 respectively; the sponge 7 is a hollow structure, and the sponge 7 is set on the connecting screw 4; the cleaning storage device 22 It includes a fixed base 8 and a protective cover 10, the fixed base 8 is connected to the protective cover 10, and the upper end surface of the fixed base 8 is provided with a slot for placing the sponge 7; the inside of the fixed base 8 is a hollow structure.

[0044] Further, if Figure 4 with Image 6 As shown, the upper part of the handle 1 is arc-shaped, an...

Embodiment 2

[0051] This embodiment provides a pipeline cleaning process, the pipeline cleaning process adopts the pipeline cleaning tool in the first embodiment, such as Figure 11 As shown, the pipeline cleaning process includes the following steps:

[0052] According to the inner diameter of the pipeline 11, the connecting screw 4 of the corresponding size is selected, and the transition joint 3 and the nut 9 matched with the connecting screw 4; the sponge 7 is selected, and in the present embodiment, the selection standard of the sponge 7 is: a little force Half of the sponge 7 can be pushed into the pipeline 11, and the sponge 7 that has entered the pipeline 11 is slightly deformed and can be pulled out with a little force.

[0053] Assembling the decontamination device 21; specifically, the steps of assembling the decontamination device 21 include: connecting the handle 1 with the universal pipe 2; connecting one end of the transition joint 3 with the universal pipe 2, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com