Device for screening and cutting short of long tobacco shreds

A technology of long and shredded tobacco, which is applied in the fields of filtering, chemical instruments and methods, solid separation, etc., and can solve the problems of broken tobacco exceeding 35 mm and unfavorable rolling of thin cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

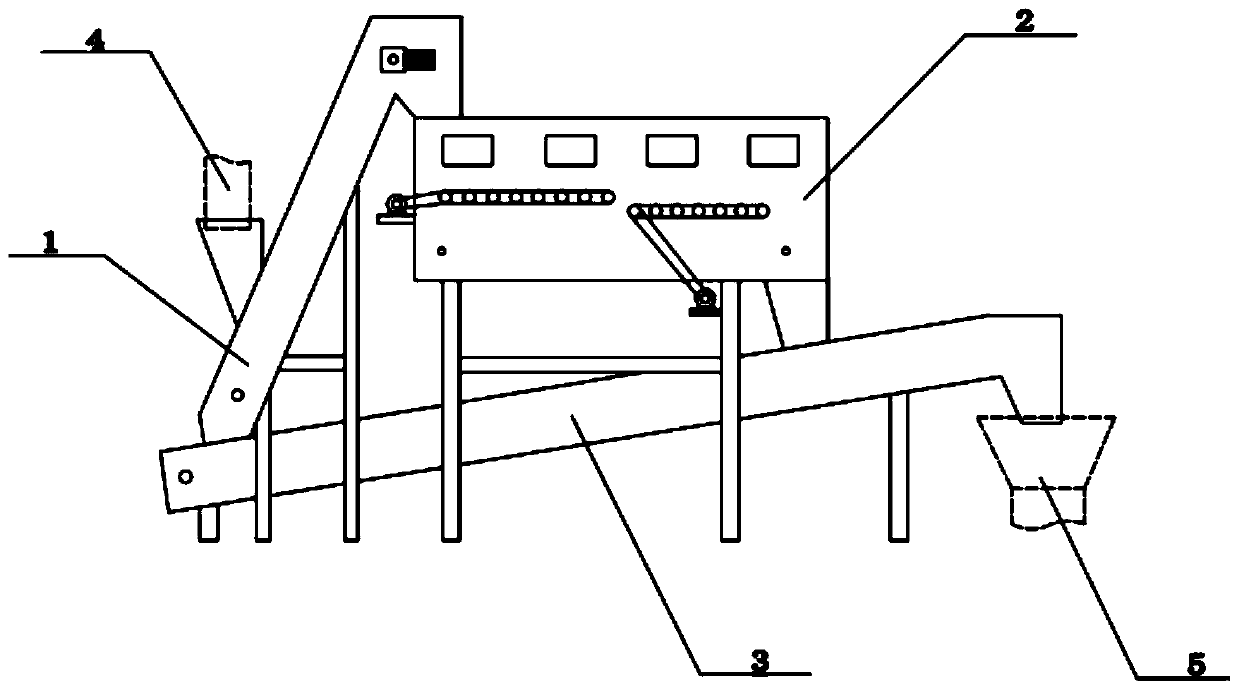

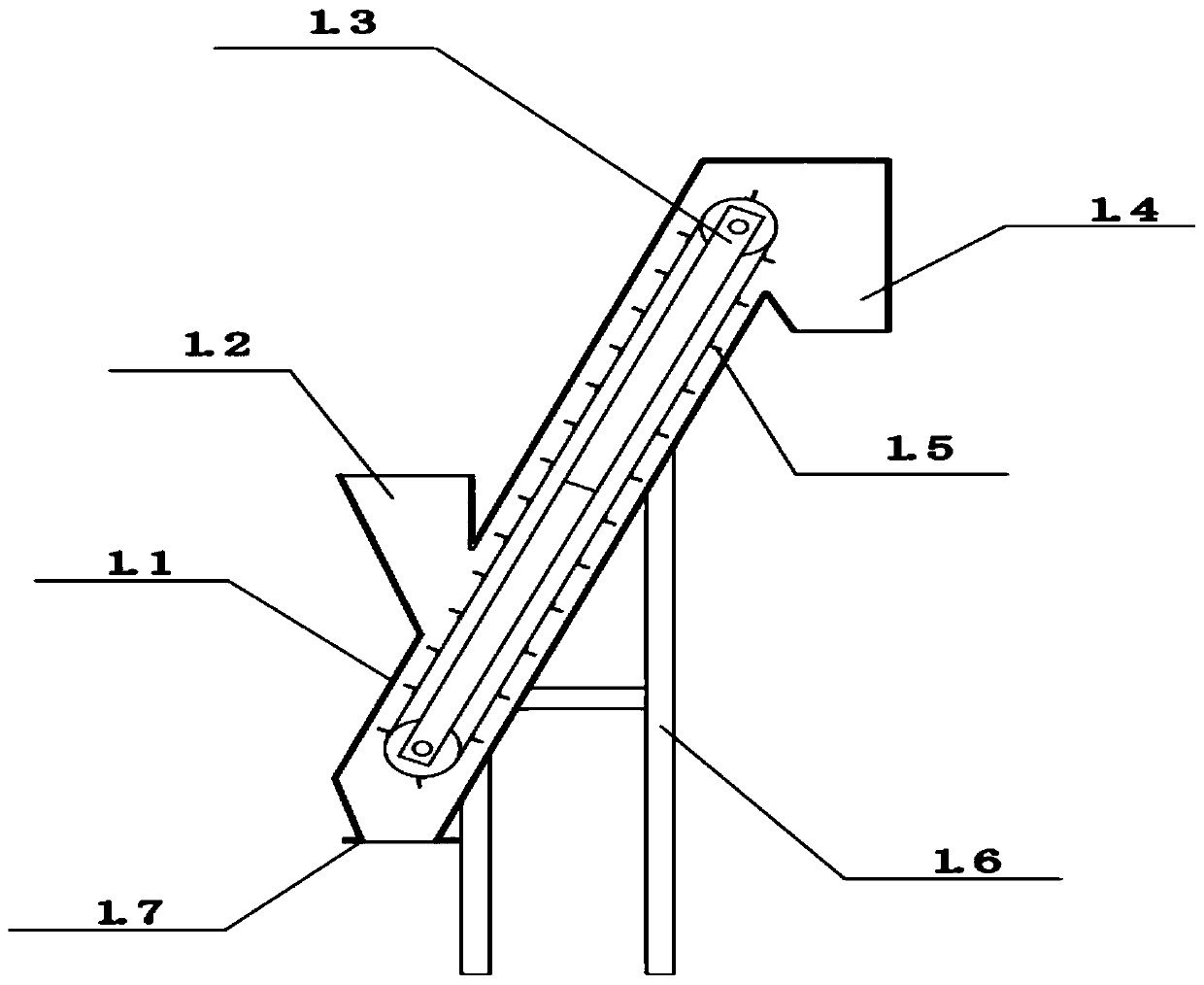

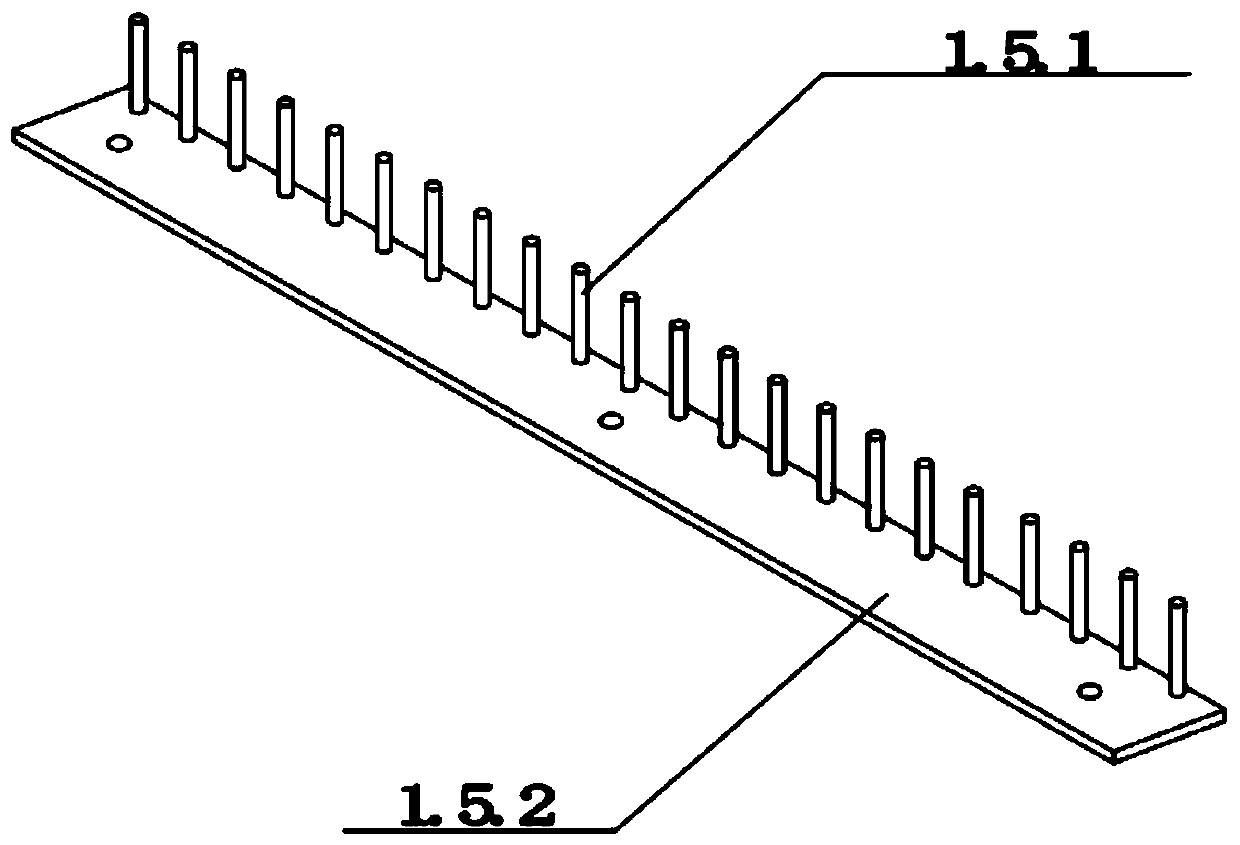

[0027] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a long shredded tobacco screening and cutting device, which includes a rake tooth sorter 1, a shredded sorter 2, and a lower conveyor 3, and the rake tooth sorter 1 is arranged at The lower part of the discharge pipe 4 of the mixed silk equipment, the shredded sorter 2 is arranged on the right side of the rake tooth sorter; the lower conveyor 3 is arranged at the bottom of the rake tooth sorter and the shredded sorter; the rake The tooth sorting machine is used to lift the long shredded tobacco in the blended shredded tobacco. The rake tooth sorting machine 1 is inclined to the left and the right is high. The main feed pipe 1.2 connected with the discharge pipe, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com