Pouring forming device applied to building material

A construction material and construction technology, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve problems affecting product quality, air bubble residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The purpose of the present invention is to provide a pouring molding device applied to building materials, aiming at solving the problem that during the pouring and molding process of concrete products, although the stirring structure and the vibration structure used can eliminate part of the air bubbles in the concrete, there will be some air bubbles. It will flow with the flow of concrete, causing air bubbles to remain, which will affect the quality of the product. To achieve the above object, the present invention provides the following technical solutions:

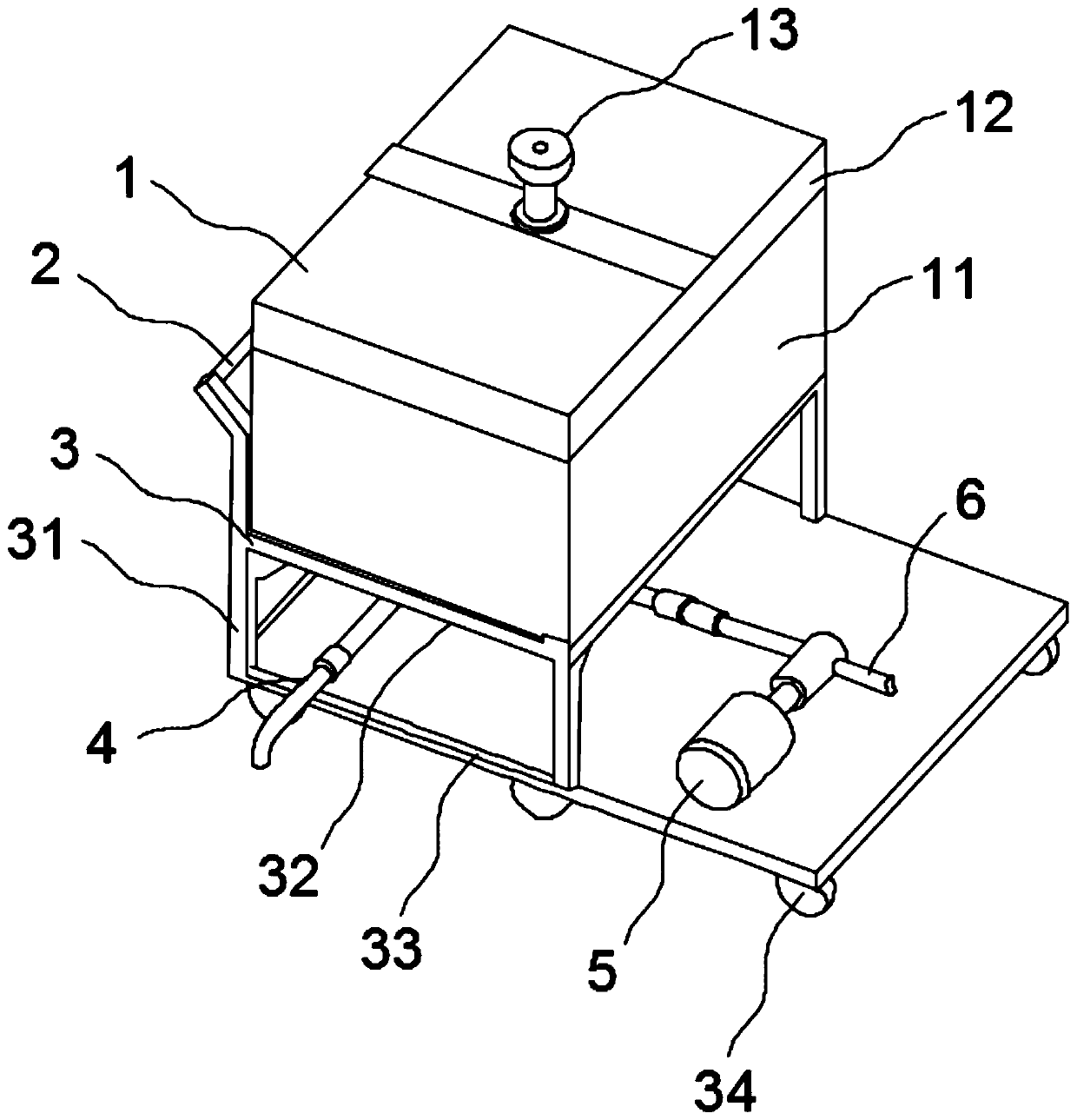

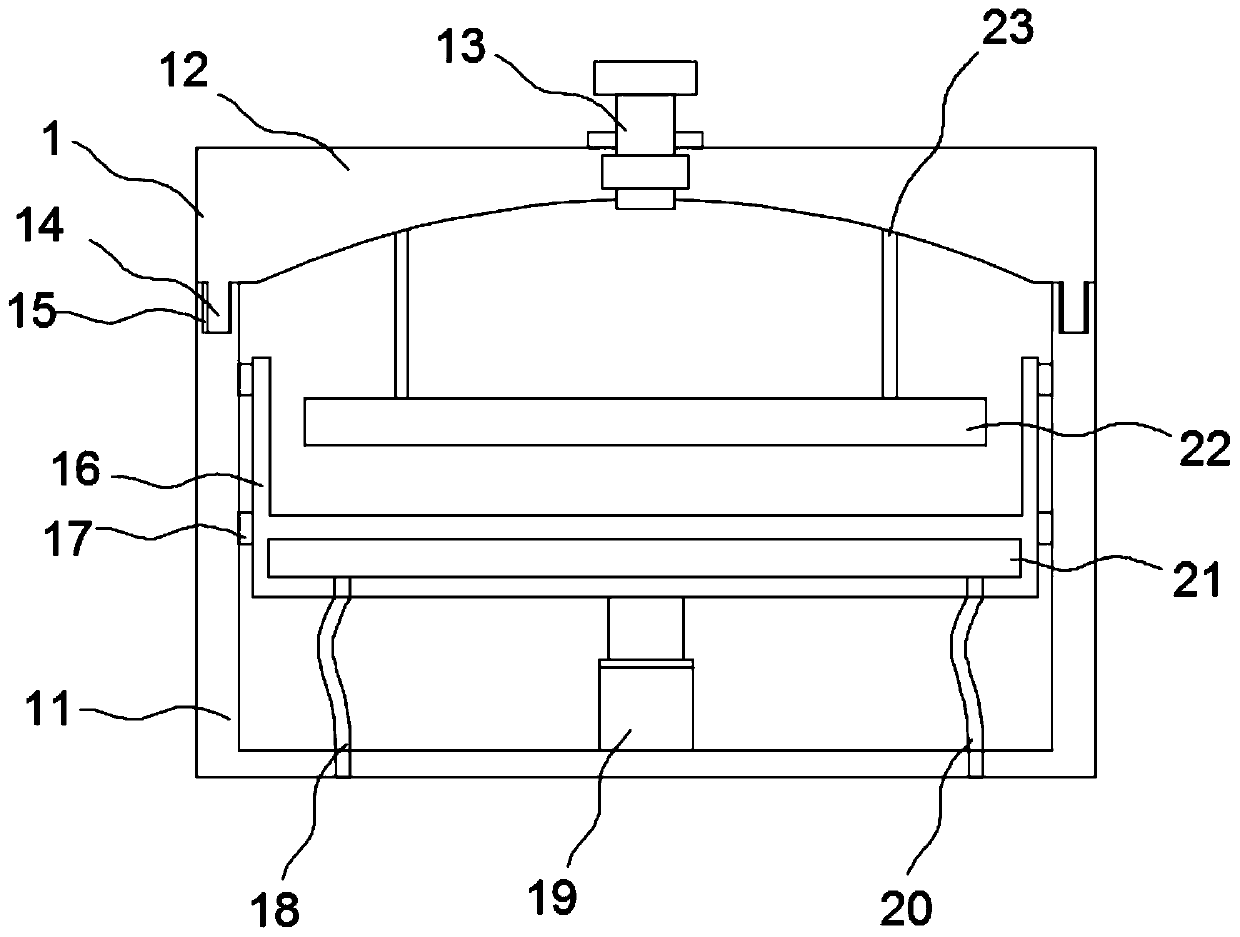

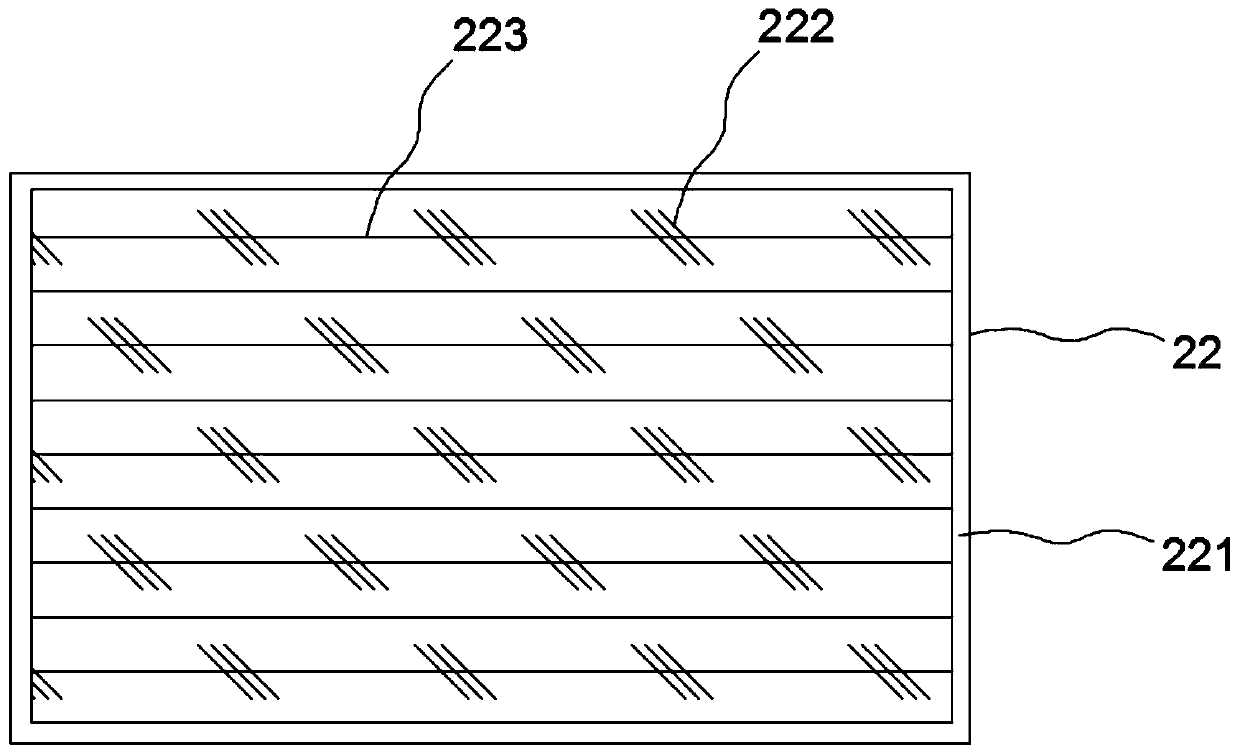

[0032] In the embodiment of the present invention, please refer to Figure 1-3 , a pouring molding device applied to building materials, including a forming box 1 supported by a support frame 3, the forming box 1 is composed of a detachably installed bottom box 11 and a cover body 12; wherein,

[0033] The cover 12 is equipped with an air extraction device 13 that can perform air extraction to form a negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com