A method for electrochemical recovery of hexavalent chromium with cus modified carbon cloth electrode

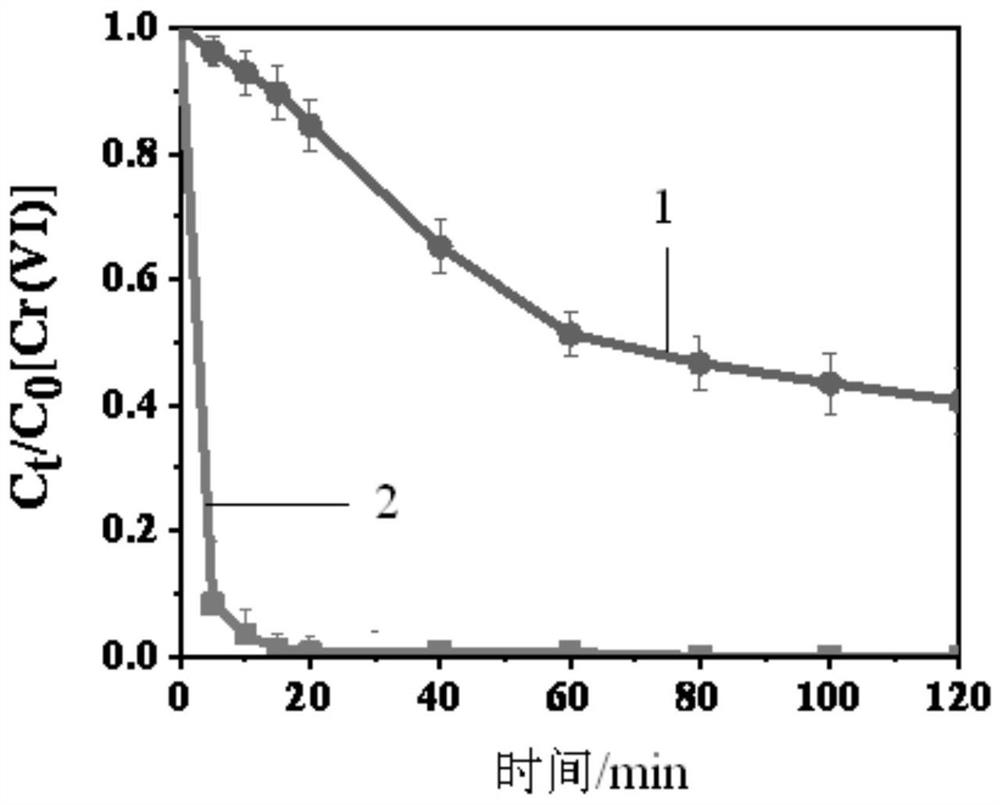

A modified carbon and hexavalent chromium technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of slow removal rate and low removal rate of hexavalent chromium, Achieve the effects of accelerating efficiency, increasing electrochemical active area, and simple electrochemical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: this embodiment is a method for electrochemically reclaiming hexavalent chromium with a CuS modified carbon cloth electrode, specifically as follows:

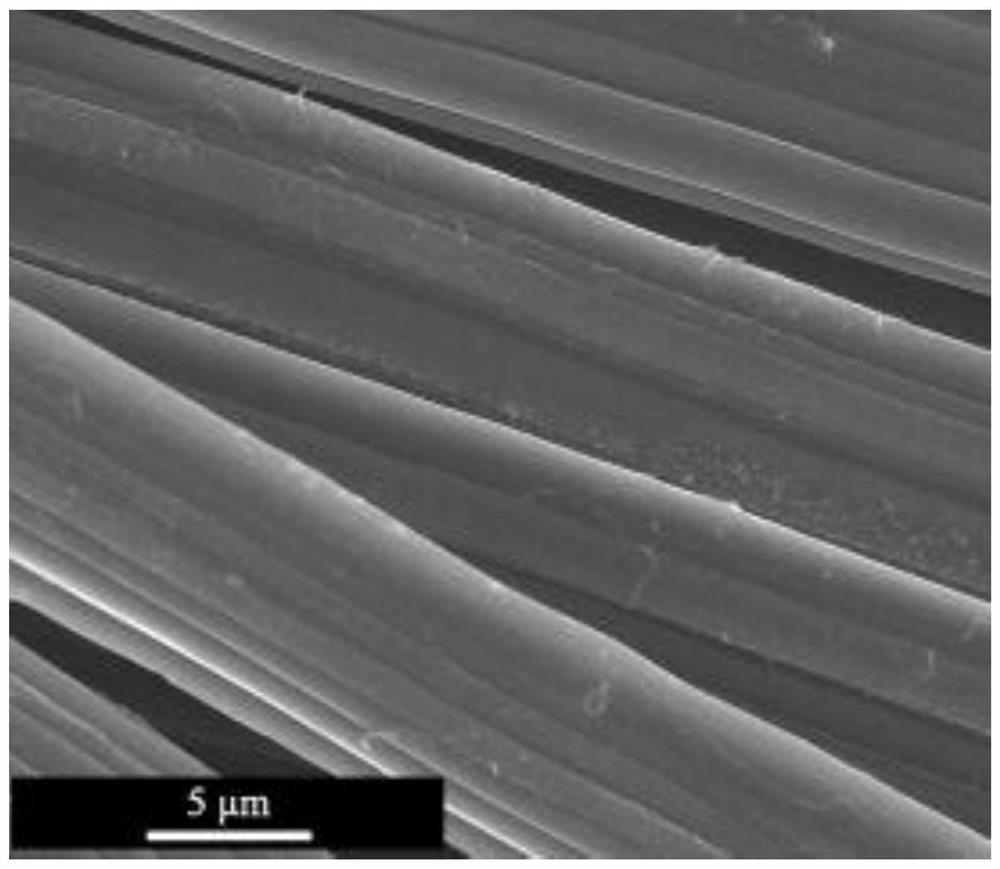

[0027] 1. Soak the carbon cloth in concentrated nitric acid aqueous solution for 24h to 25h, then rinse it with deionized water until it becomes neutral, and then dry it at 80°C to 85°C for 2h to 2.5h to obtain acidic carbon cloth;

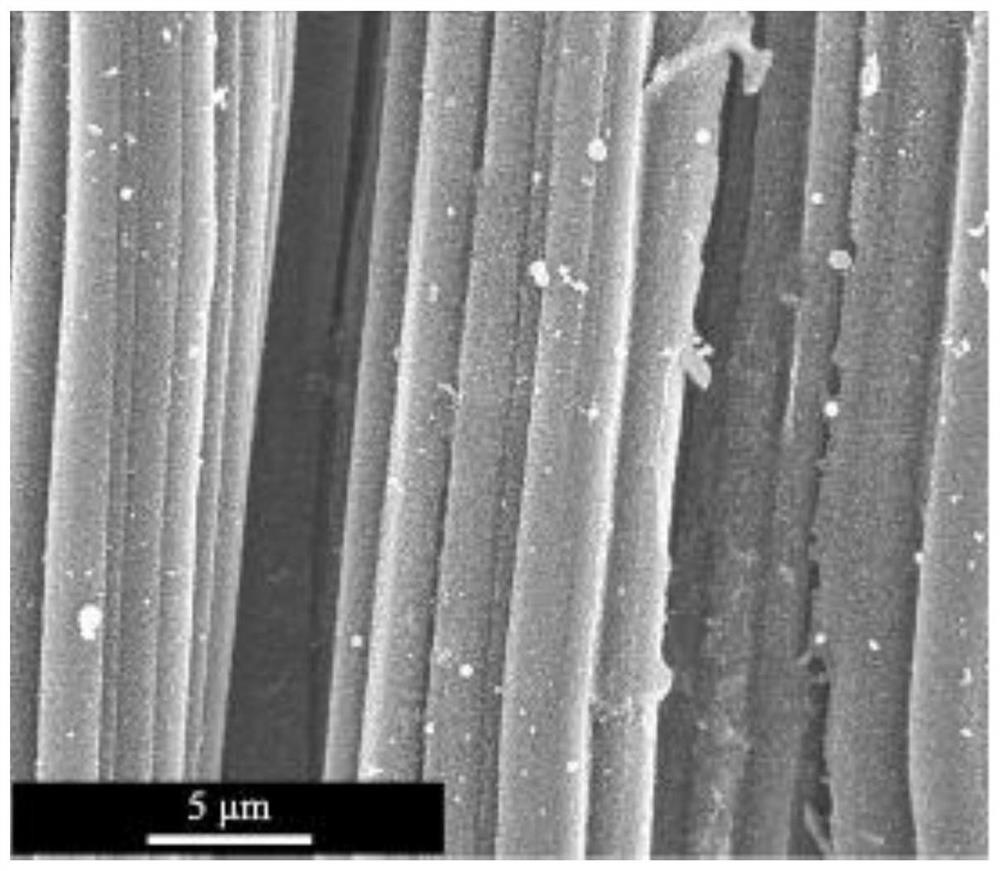

[0028] 2. Dissolve copper sulfate pentahydrate and thioacetamide together in deionized water and stir for 30-40 minutes to obtain a mixed solution, then put it into a polytetrafluoroethylene autoclave, and then put the acidic carbon cloth prepared in step 1 completely Immerse in the mixed solution, react at 180°C to 190°C for 12h to 13h, then take out the carbon cloth and wash it with deionized water, and then dry it at 80°C to 90°C for 3h to 4h to obtain a CuS modified carbon cloth electrode;

[0029] The mass ratio of described copper sulfate pentahydrate and thioa...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carbon cloth model described in step 1 is HCP331N. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass fraction of the concentrated nitric acid aqueous solution described in step one is 69%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com