A rectangular molding device for cement pavement embossing

A cement pavement, rectangular technology, applied in the field of embossing molding devices, can solve the problems of poor control of embossing depth, easy to leave footprints, etc., and achieve the effect of convenient embossing, rapid embossing, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

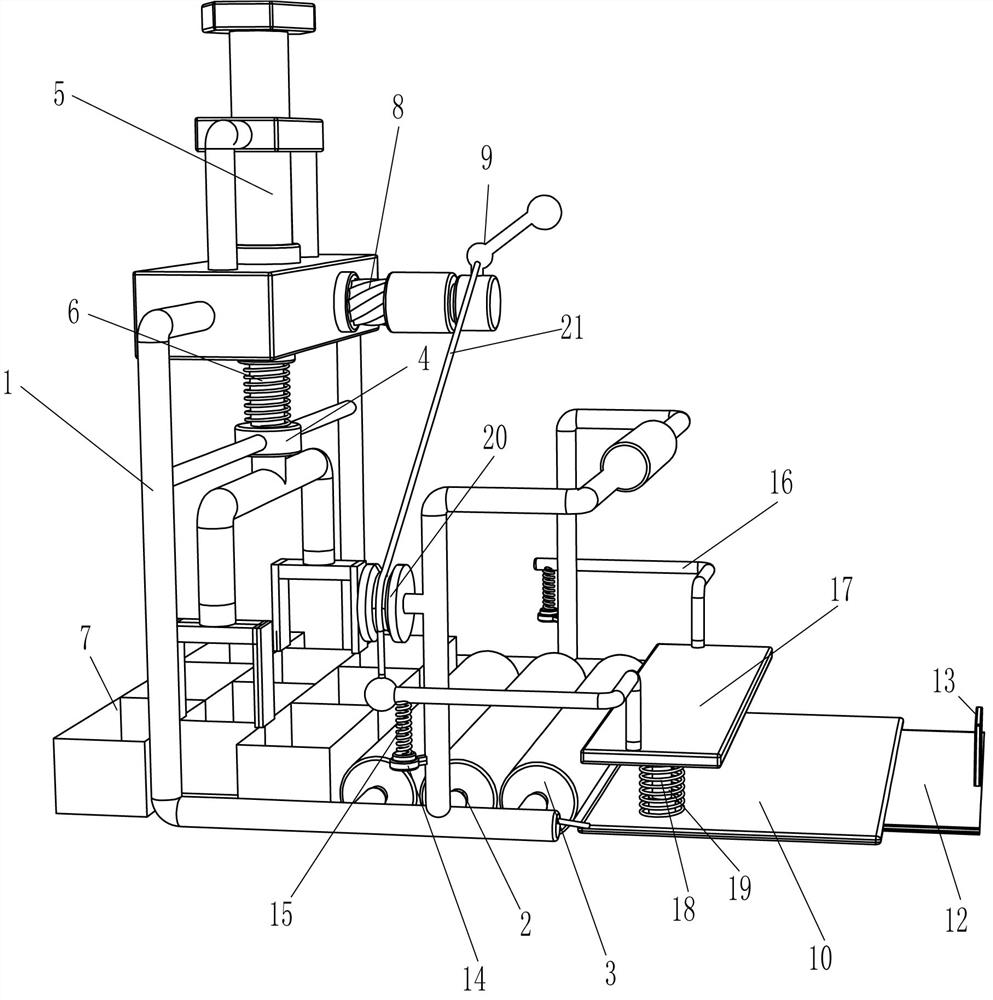

[0018] A cement pavement embossing rectangular molding device, such as figure 1 with 2 As shown, it includes a frame 1, a flattening assembly, an embossing assembly and a bottom plate 10. The middle part of the frame 1 is provided with a flattening assembly for flattening by rotation. The embossing assembly printed, the right part of the frame 1 is fixed with a bottom plate 10 by bolts.

[0019] Such as figure 1 As shown, the flattening assembly includes a connecting rod 2 and a rotating cylinder 3, three connecting rods 2 are rotatably arranged in the middle of the frame 1, and a rotating drum 3 is uniformly arranged on the connecting rod 2.

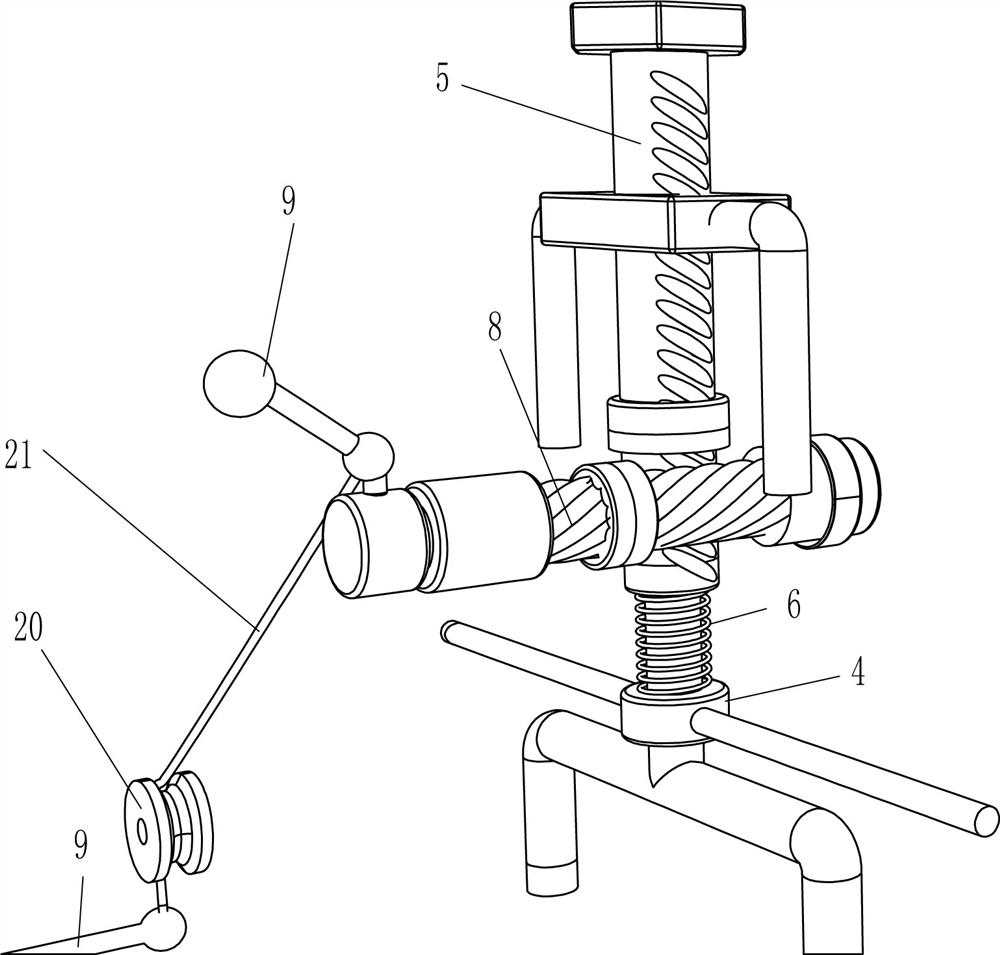

[0020] Such as figure 1 with 2 As shown, the embossing assembly includes a guide sleeve 4, a helical rack 5, a first spring 6, a printing template 7, a helical gear 8 and a handle 9, a guide sleeve 4 is welded in the middle of the left part of the frame 1, and the inside of the guide sleeve 4 The sliding type is equipped with a hel...

Embodiment 2

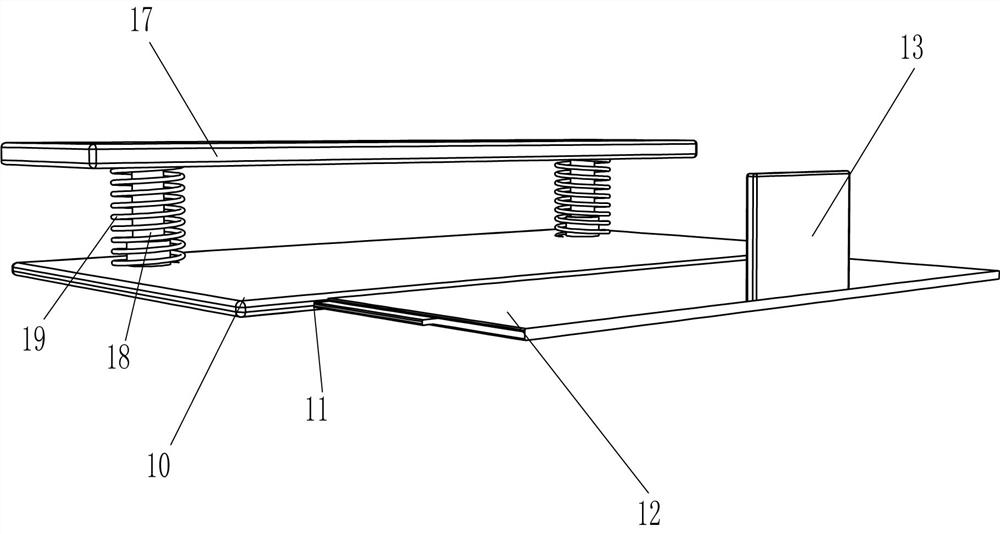

[0025] On the basis of Example 1, such as figure 1 with 3 Shown, also include mobile plate 12 and push plate 13, base plate 10 bottom right side has chute 11, sliding type is provided with mobile plate 12 in chute 11, and mobile plate 12 top right side is provided with push plate 13.

[0026] Such as figure 1 with 2 As shown, it also includes a connection block 14, a second spring 15, a special-shaped connecting rod 16, a pressing plate 17, a lifting and shrinking rod 18, a third spring 19, a fixed pulley 20 and a backguy 21, and the top of the bottom plate 10 is symmetrically provided with a lifting and shrinking rod. 18. There is a pressure plate 17 between the tops of the lifting and retracting rods 18, a third spring 19 is connected between the pressure plate 17 and the bottom plate 10, the top of the pressure plate 17 is symmetrically provided with special-shaped connecting rods 16, and the middle part of the frame 1 is symmetrically provided with connecting blocks 14....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com