Concrete form supporting device for constructional engineering

A technology of concrete formwork and construction engineering, applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems of heavy workload, time-consuming and laborious, difficult to guarantee the quality of support, etc., and achieve the effect of heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

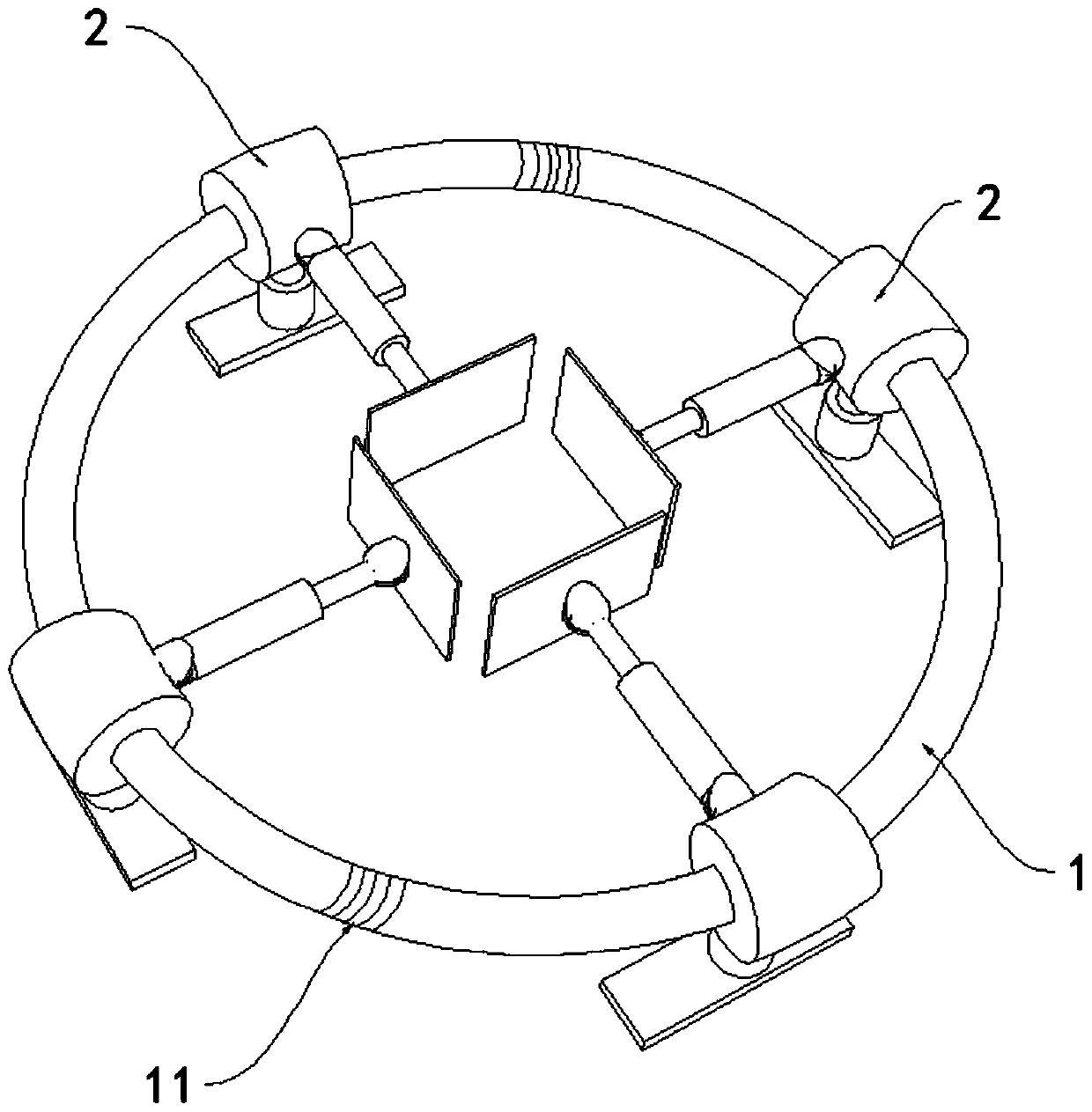

[0033] A concrete formwork support device for construction engineering provided by a preferred embodiment of the present invention includes a guide ring 1 and four adjustable support assemblies 2 for supporting concrete in cooperation with each other, and the adjustable support assemblies 2 are installed on the guide ring 1 on;

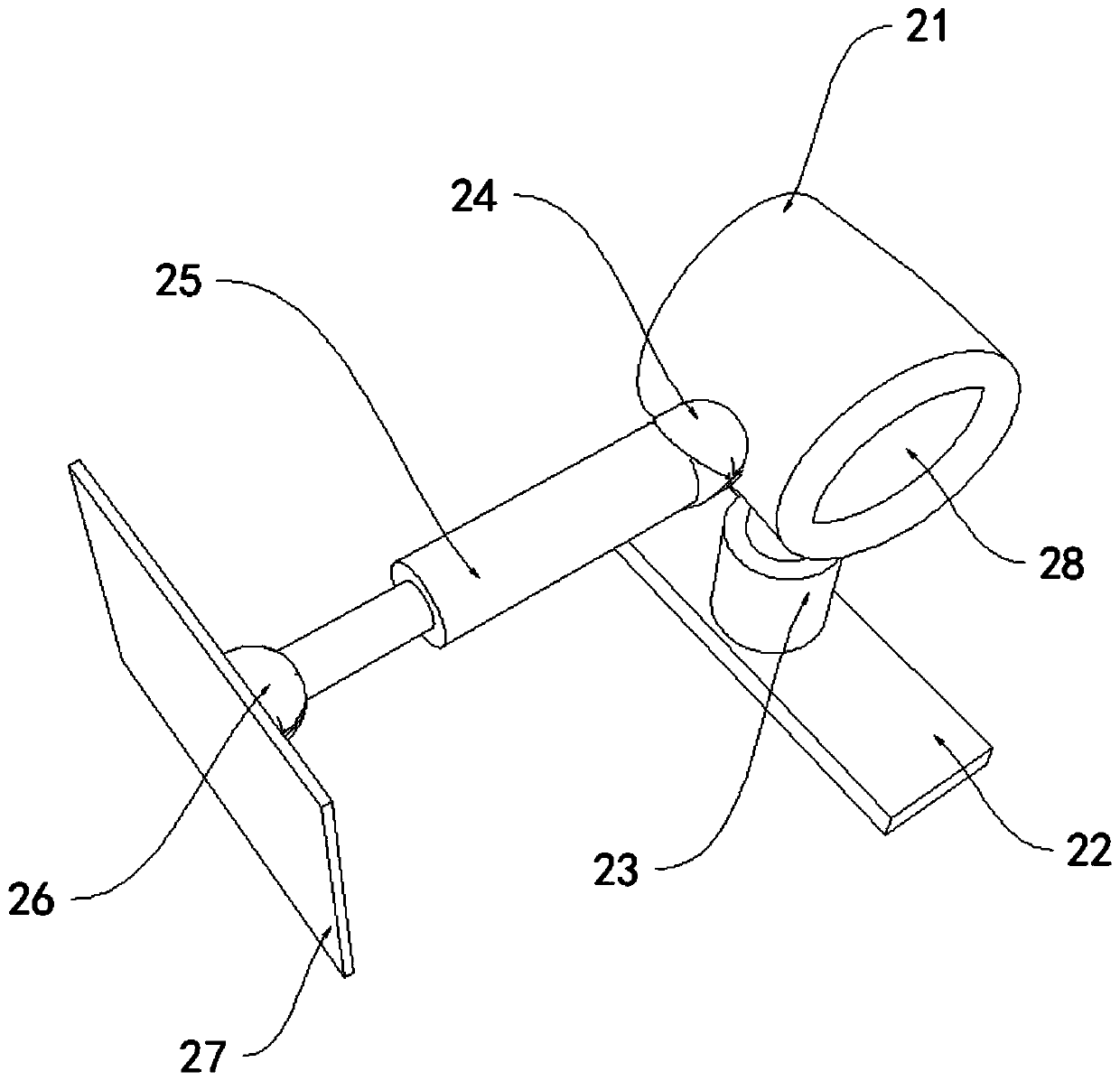

[0034]The adjustable support assembly 2 includes a sliding sleeve 21, a base 22, a height adjustment frame 23, a first rotating joint 24, a horizontal distance adjusting rod 25, a second rotating joint 26, and a support plate 27. The sliding sleeve 21 A through hole 28 is provided on the axis, and the through hole 28 can pass through the guide ring 1. The sliding sleeve 21 is slidably connected with the guide ring 1 through the through hole 28. One end of the height adjustment frame 23 is connected to the bottom of the sliding sleeve 21. One end of the height adjustment frame 23 away from the sliding sleeve 21 is connected to the base 22, the first ro...

Embodiment 2

[0037] This embodiment is further optimized on the basis of Embodiment 1. This embodiment provides a concrete formwork support device for construction engineering, including a guide ring 1, and 4 adjustable support assemblies 2 for supporting concrete in cooperation with each other. The adjustable support assembly 2 is installed on the guide ring 1;

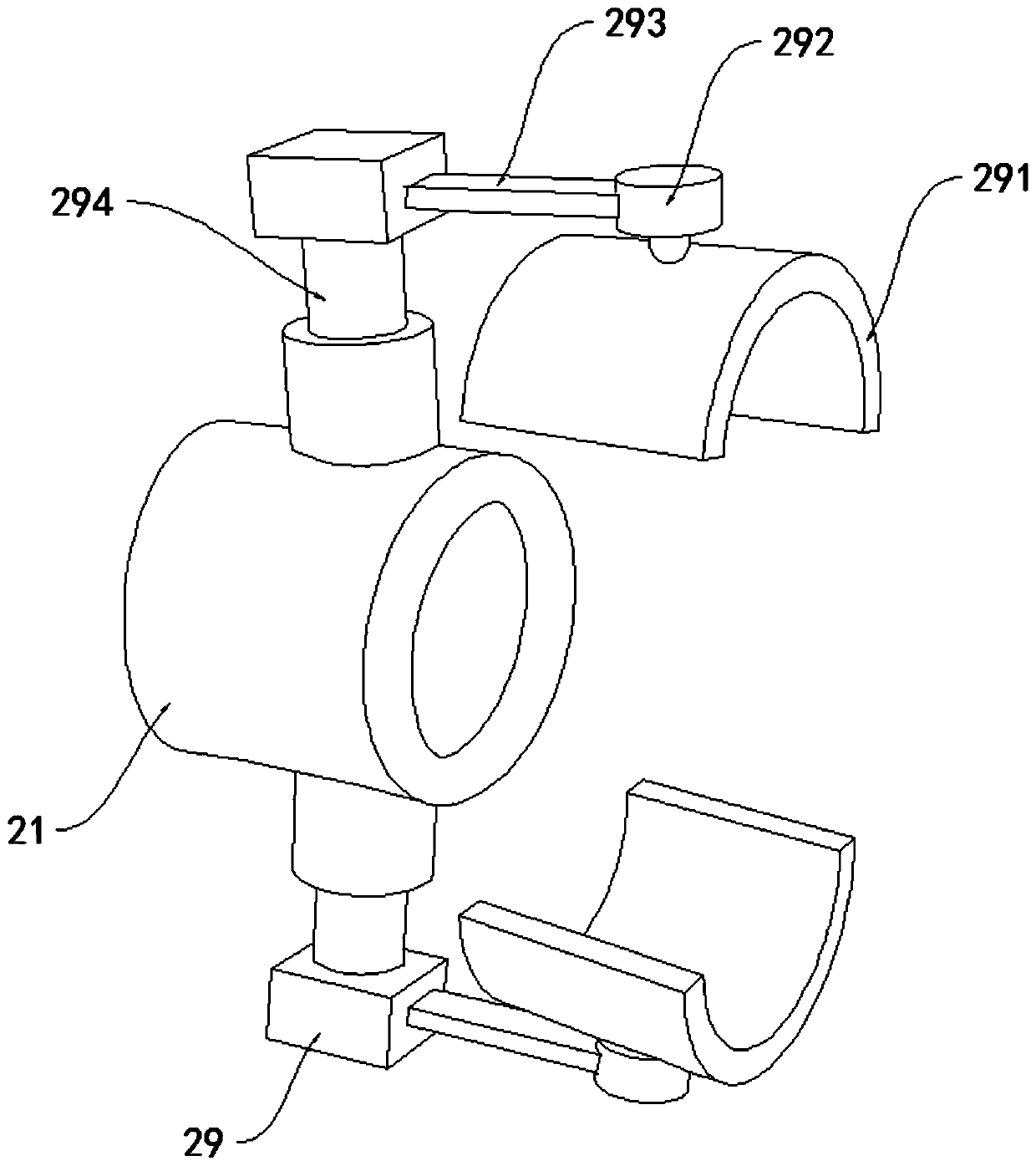

[0038] The adjustable support assembly 2 includes a sliding sleeve 21, a base 22, a height adjustment frame 23, a first rotating joint 24, a horizontal distance adjusting rod 25, a second rotating joint 26, and a support plate 27. The sliding sleeve 21 A through hole 28 is provided on the axis, and the through hole 28 can pass through the guide ring 1. The sliding sleeve 21 is slidably connected with the guide ring 1 through the through hole 28. One end of the height adjustment frame 23 is connected to the bottom of the sliding sleeve 21. One end of the height adjustment frame 23 away from the sliding sleeve 21 is connected to th...

Embodiment 3

[0041] This embodiment is further optimized on the basis of Embodiment 1. This embodiment provides a concrete formwork support device for construction engineering, including a guide ring 1, and 4 adjustable support assemblies 2 for supporting concrete in cooperation with each other. The adjustable support assembly 2 is installed on the guide ring 1;

[0042] The adjustable support assembly 2 includes a sliding sleeve 21, a base 22, a height adjustment frame 23, a first rotating joint 24, a horizontal distance adjusting rod 25, a second rotating joint 26, and a support plate 27. The sliding sleeve 21 A through hole 28 is provided on the axis, and the through hole 28 can pass through the guide ring 1. The sliding sleeve 21 is slidably connected with the guide ring 1 through the through hole 28. One end of the height adjustment frame 23 is connected to the bottom of the sliding sleeve 21. One end of the height adjustment frame 23 away from the sliding sleeve 21 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com