Novel fin arranging machine for fin evaporator

A technology of finned evaporator and sheet arranging machine, applied in heat exchange equipment, etc., can solve the problems of scratches, low production efficiency, wrong arrangement, etc., and achieve the effect of fast sheet arranging and no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

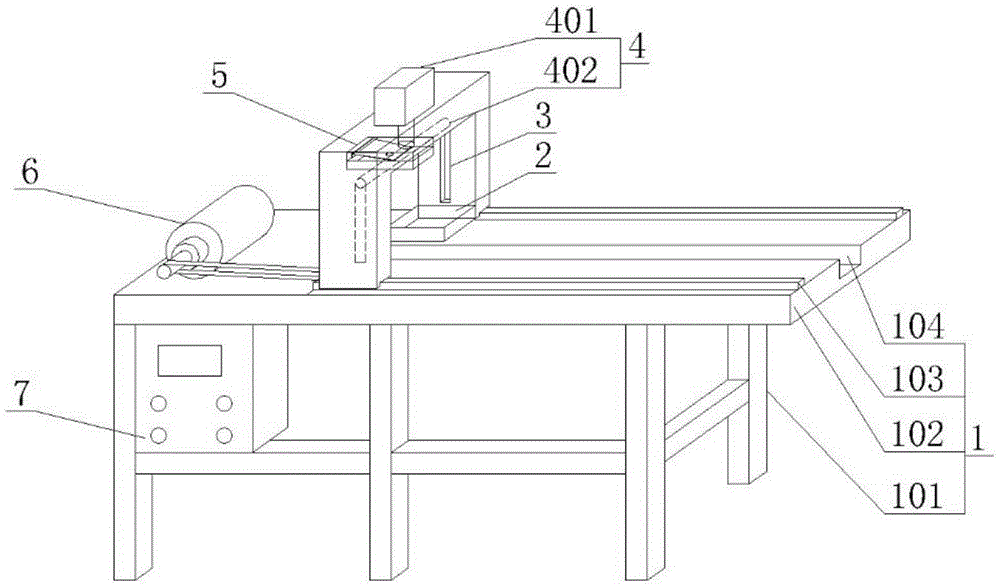

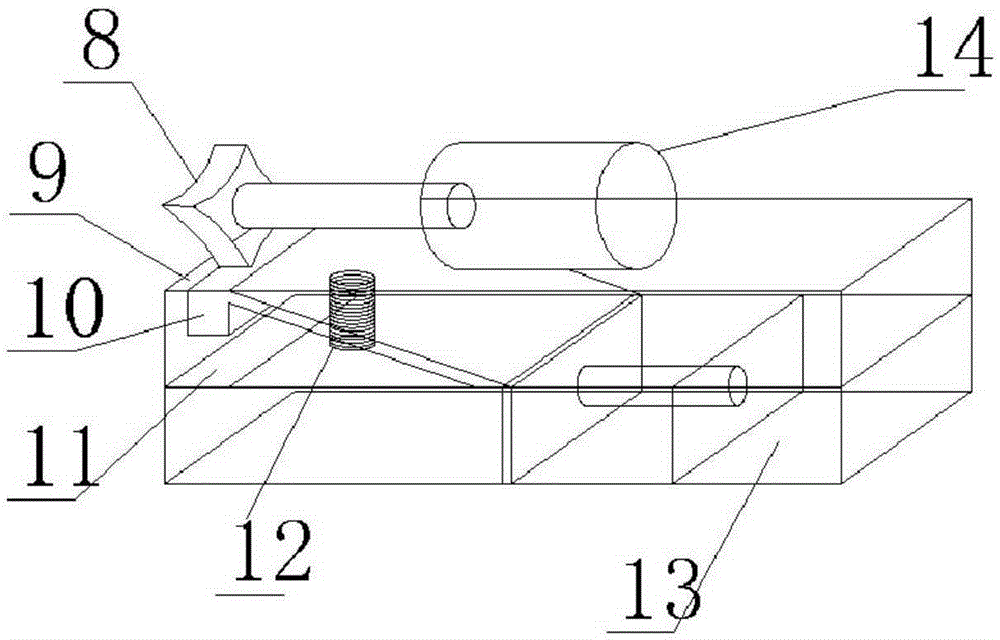

[0015] See accompanying drawing: a kind of novel fin evaporator slice machine, it is characterized in that comprising sheet arrangement trolley 4, sheet arrangement device 5, sheet arrangement platform 1, fin feeding box 2, power motor 6 and programming controller 7, described sheet arrangement trolley 4 The shape is 'n' shape, there is a push cylinder 401 and a screw slide rail 402 on the sheet arranging trolley 4, and the sheet arranging device 5 includes fin holders (8, 9, 11, 13), sheet arranging motor 14, and sheet arranging thimble 10 With the sheet-arranging spring 12, the sheet-arranging platform 1 includes a bracket 101, a flat plate with a concave groove 102 and two linear slide rails 103, and the fin feeding box 2 is located between the vertical plate of the sheet-arranging trolley 4 and the concave groove 104. The programming controller 7 adopts PLC programming control, and the surface of the programming controller 7 has a data display and adjustment buttons. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com