Abrasion-resistant three-dimensional sand suction pump and working method thereof

A sand suction pump, three-dimensional technology, applied in the direction of pumps for special fluids, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as the wear of the mixing head, achieve improved wear resistance, convenient replacement, and improved Stirring effect and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

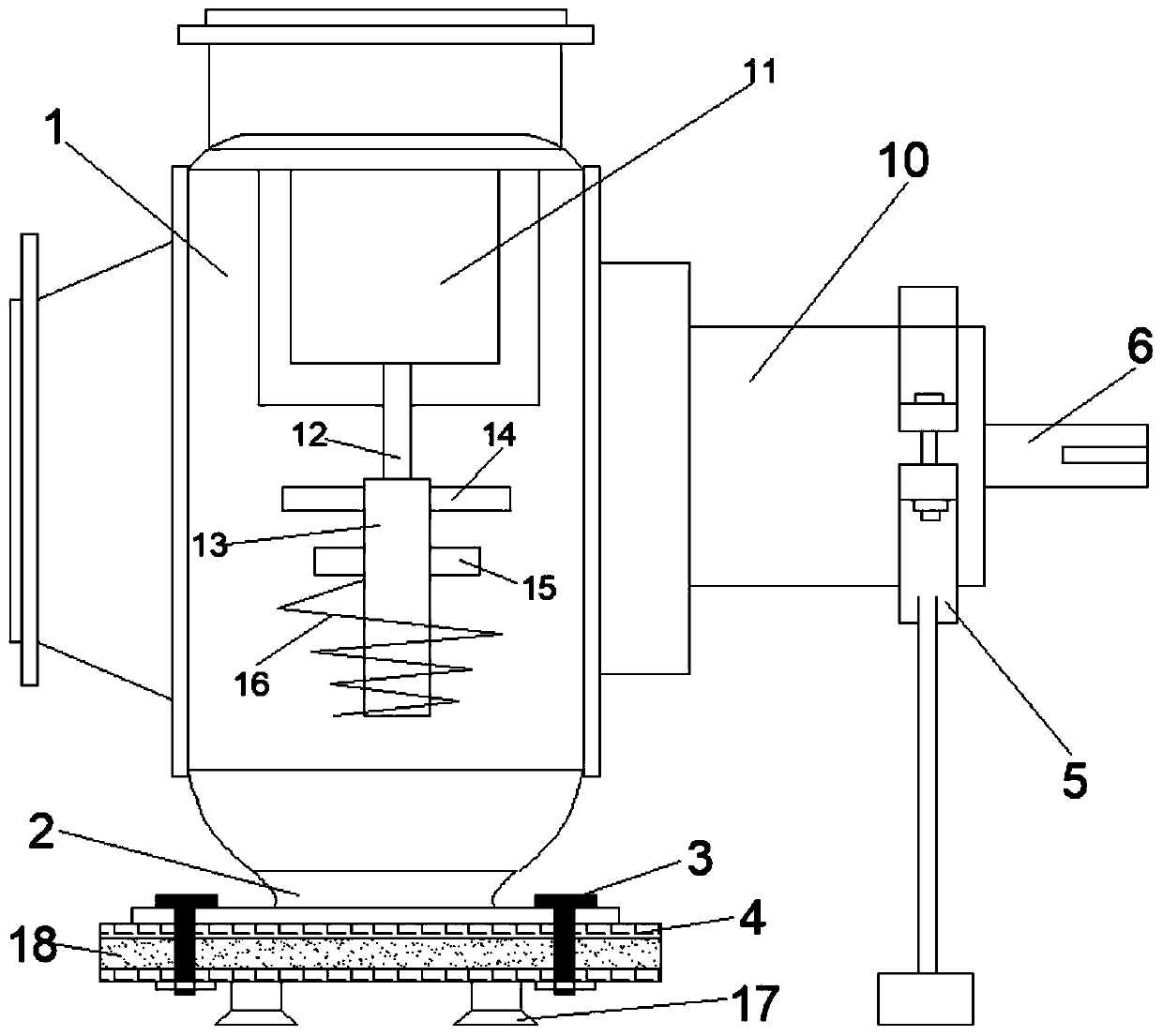

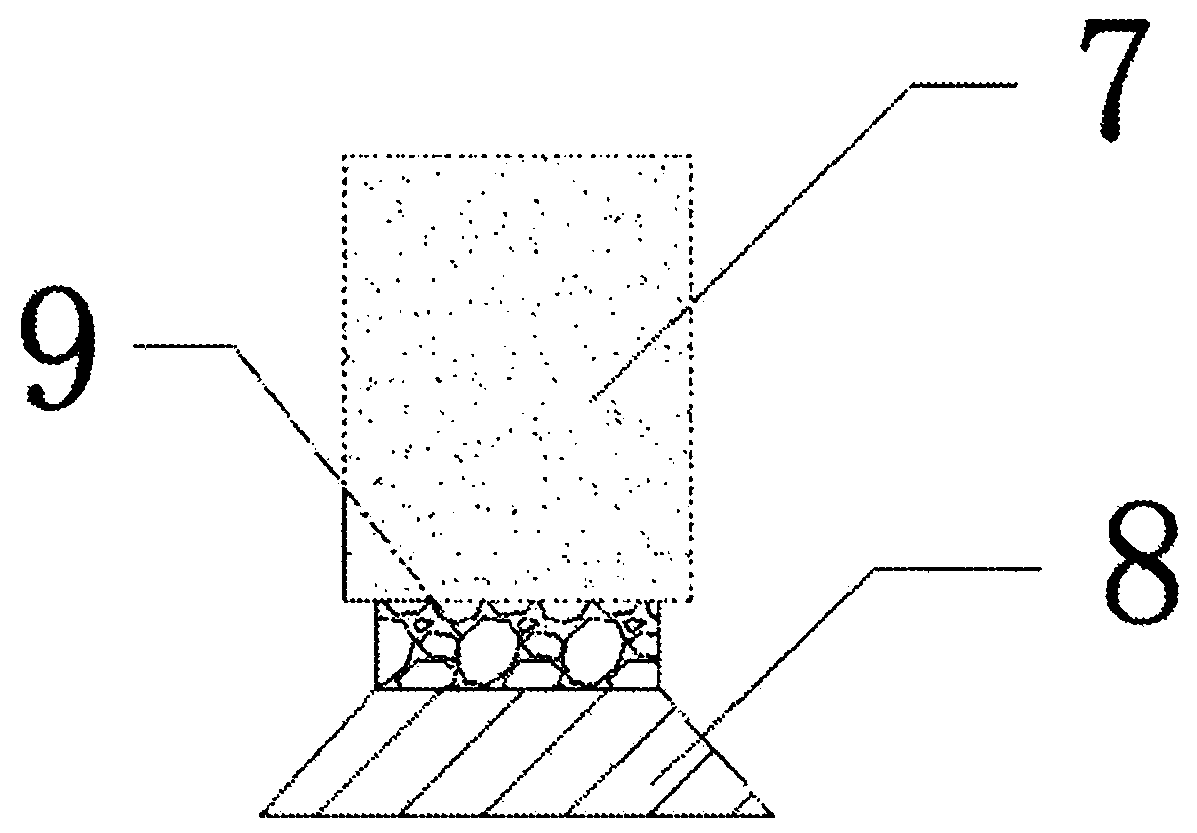

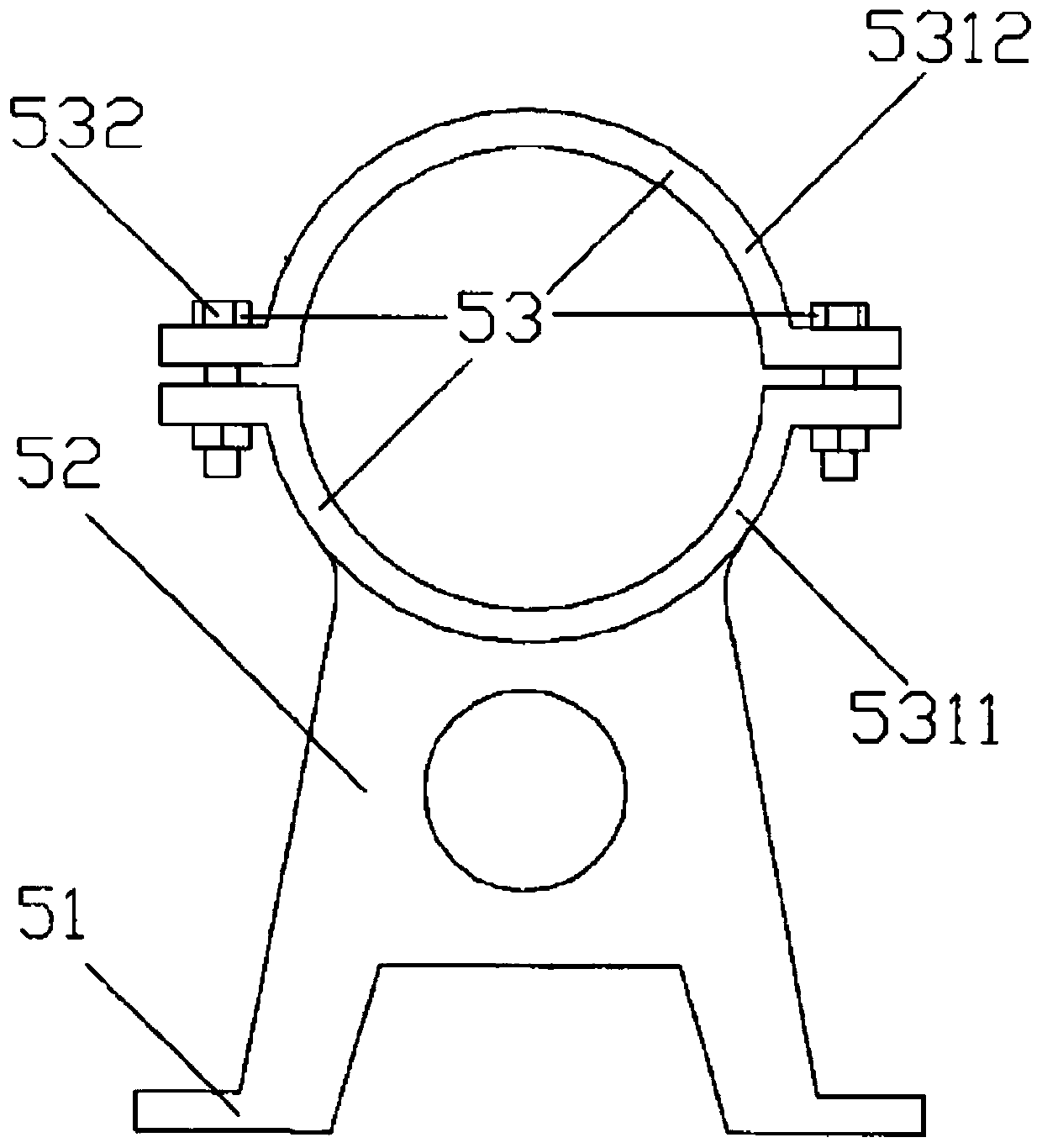

[0024] Such as Figure 1-2 The wear-resistant three-dimensional sand suction pump shown includes a pump body 1, a base 2, a buffer adjustment device, an adjustable bearing seat bracket 5, a pump shaft 6, a bearing seat 10 and a stirring device, and a base 2 is provided under the pump body 1 , the base 2 is provided with a buffer adjustment device, the pump body 1 is connected to a bearing seat 10, and the pump shaft 6 is sleeved inside the bearing seat 10, and the bearing seat 10 is supported by an adjustable bearing seat bracket 5. The pump body 1 is provided with a stirring device; wherein, the buffer adjustment device includes a stud 3, a fixed splint 4, a stabilizing system 17 and a rubber buffer layer 18, and the two fixed splints 4 are arranged in parallel on both sides of the rubber buffer layer 18 , the four studs 3 are arranged at four right angles of the fixing splint 4, the upper end of the fixing splint 4 is connected to the base 2, the studs 3 pass through the bas...

Embodiment 2

[0029] Such as Figure 1-2 The wear-resistant three-dimensional sand suction pump shown includes a pump body 1, a base 2, a buffer adjustment device, an adjustable bearing seat bracket 5, a pump shaft 6, a bearing seat 10 and a stirring device, and a base 2 is provided under the pump body 1 , the base 2 is provided with a buffer adjustment device, the pump body 1 is connected to a bearing seat 10, and the pump shaft 6 is sleeved inside the bearing seat 10, and the bearing seat 10 is supported by an adjustable bearing seat bracket 5. The pump body 1 is provided with a stirring device; wherein, the buffer adjustment device includes a stud 3, a fixed splint 4, a stabilizing system 17 and a rubber buffer layer 18, and the two fixed splints 4 are arranged in parallel on both sides of the rubber buffer layer 18 , the four studs 3 are arranged at four right angles of the fixing splint 4, the upper end of the fixing splint 4 is connected to the base 2, the studs 3 pass through the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com