Multifunctional slope model test device

A model test device and multi-functional technology, applied in soil material testing, material inspection products, etc., can solve the problems of incomplete data, single function, inability to consider the influence of various factors, etc., to achieve easy operation, improve reliability, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

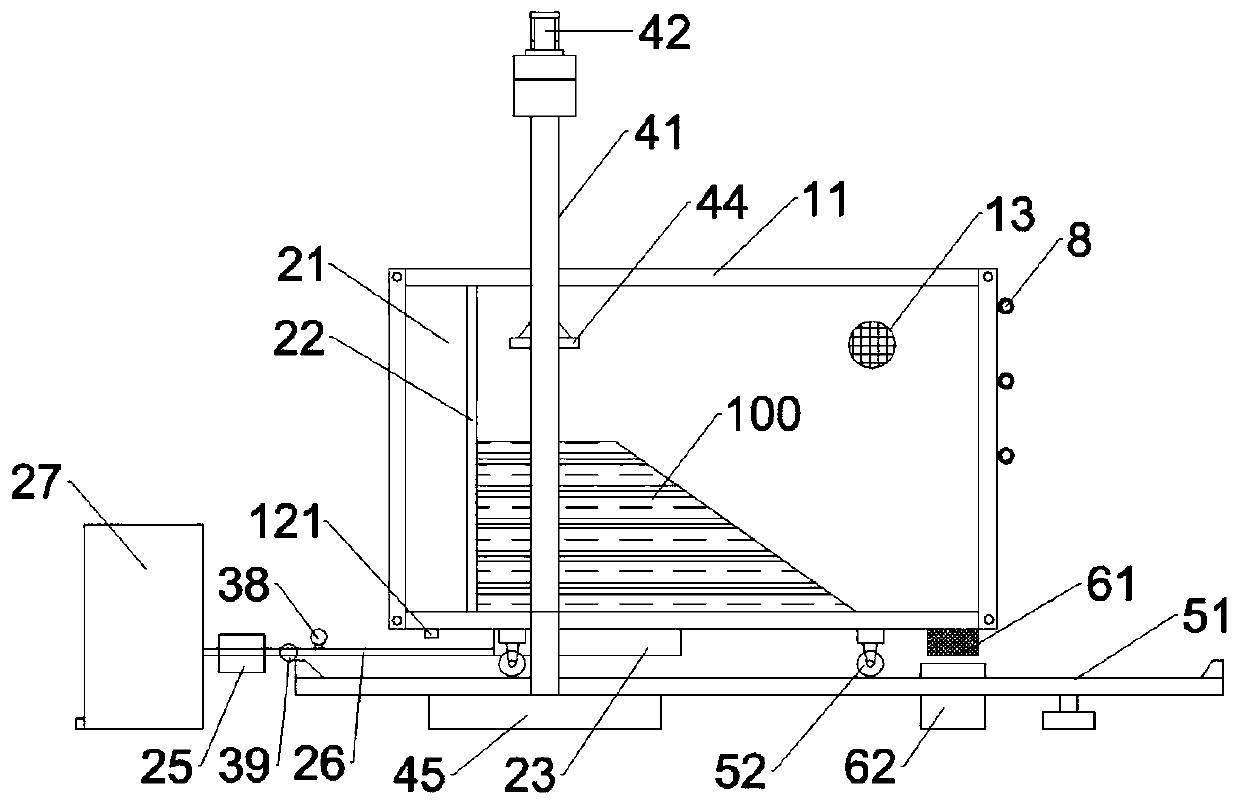

Embodiment 1

[0067] When carrying out the slope model test under the action of rainfall, the specific steps are: 1) unload the supporting struts from the metal frame 11 of the model box, move the prepared test soil into the model box, and fill it with layered tamping 2) install the rainfall cover 31 to the top of the model box; 3) adjust the rainfall intensity, rainfall duration and rainfall through the rainfall console 36 Wait for the rainfall parameters, then open the valve to start raining, the water flow of the rainfall process can be accurately recorded by the flowmeter 38; 4) fix and open the high-speed camera 71 and the computer 72, the deformation of the side slope in the test process can be accurately recorded by the PIV data acquisition system situation and rainwater infiltration; 5) the muddy water is separated by the drainage filter tank 61, and the separated water is collected by the water collection tank 62, and the amount of slope erosion and rainwater infiltration in the tes...

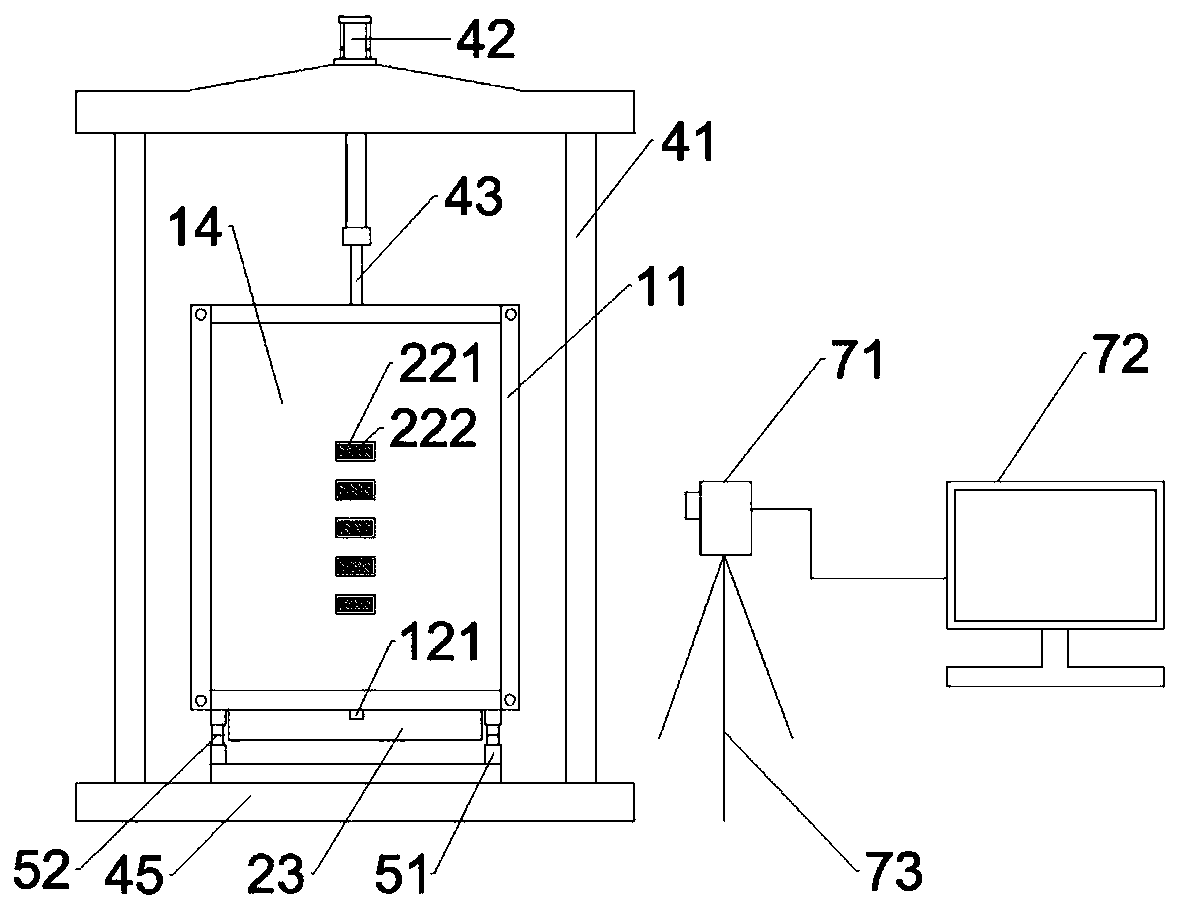

Embodiment 2

[0069] When carrying out the slope model test under the joint action of rainfall and groundwater seepage, the specific steps are: 1) unload the support rod 8 from the right side of the model box, move the prepared test soil into the model box, and use layered compaction The filling method fills the slope model, and reinstalls the support rod 8 after filling; 2) installs the rainfall cover 31 on the top of the model box; 3) seals the water outlet 121, and keeps the water head constant according to the design required for the experiment Fill water to the corresponding height in the side water injection tank 21 at the height, and unplug the plug body 222 at the overflow port 221 at the height, and connect the drain pipe on the outside so that the water higher than the height can be discharged through the overflow port 221, thereby Keep a constant water head, at this time, water begins to enter the slope model through the side permeable plate 22, forming side groundwater seepage; 4...

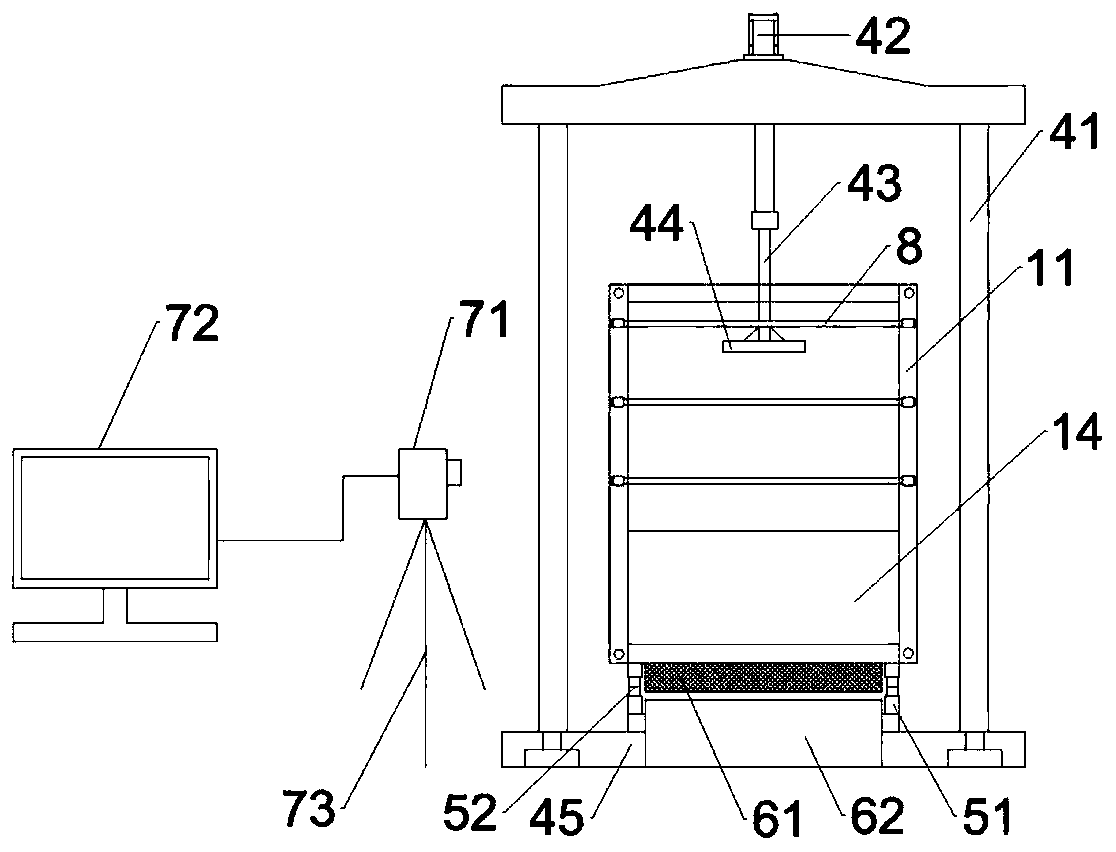

Embodiment 3

[0071] When carrying out the slope model test under the joint action of rainfall, groundwater seepage and loading, the specific steps are: 1) unload the support rod 8 from the side of the model box, move the prepared test soil into the model box, and use Fill the slope model with the layer-by-layer compaction filling method, and reinstall the support rod 8 after filling; 2) install the rainfall cover 31 on the top of the model box; 3) block the water outlet 121, according to the design required for the experiment Fill water into the side water injection tank 21 at a constant water head height to a corresponding height, and unplug the plug body 222 at the overflow port 221 at this height, and connect a drain pipe on the outside so that water higher than this height is discharged through the overflow port 221, In order to maintain a constant water head, water begins to enter the slope model through the side permeable plate 22 at this time, forming groundwater seepage on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com