A Broadband and Low Eddy Current Loss Artificial Conductor

An eddy current loss and artificial technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, magnetic objects, etc., can solve the problem of narrow suppression frequency band and achieve the effect of solving the problem of narrow suppression frequency band and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

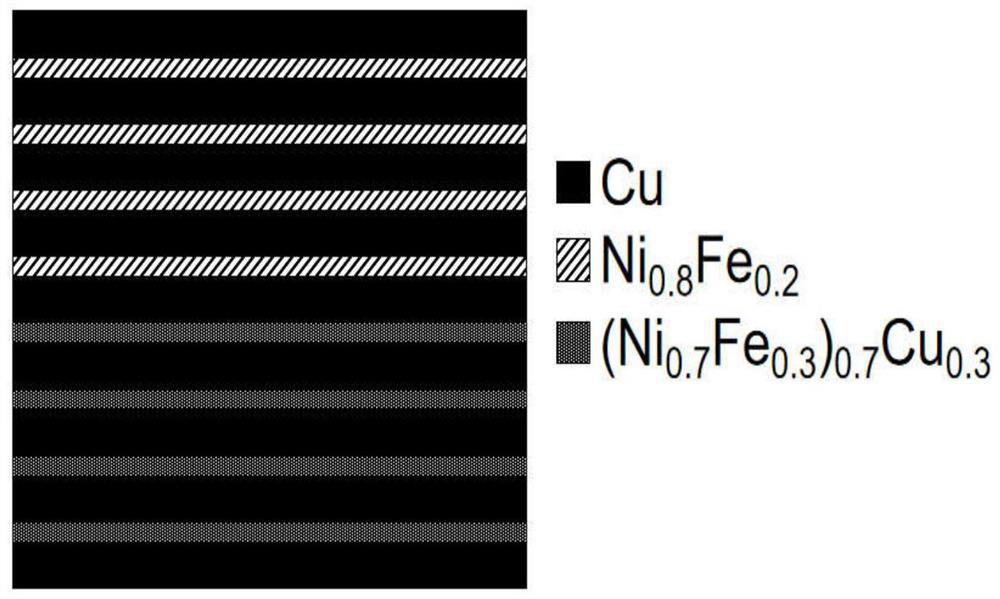

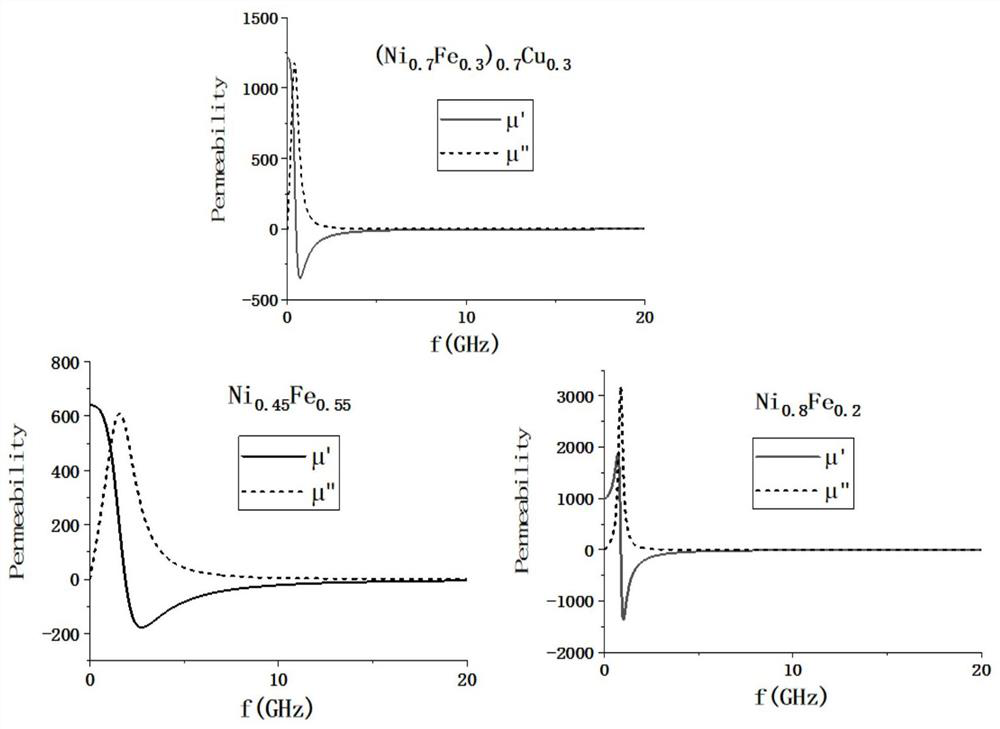

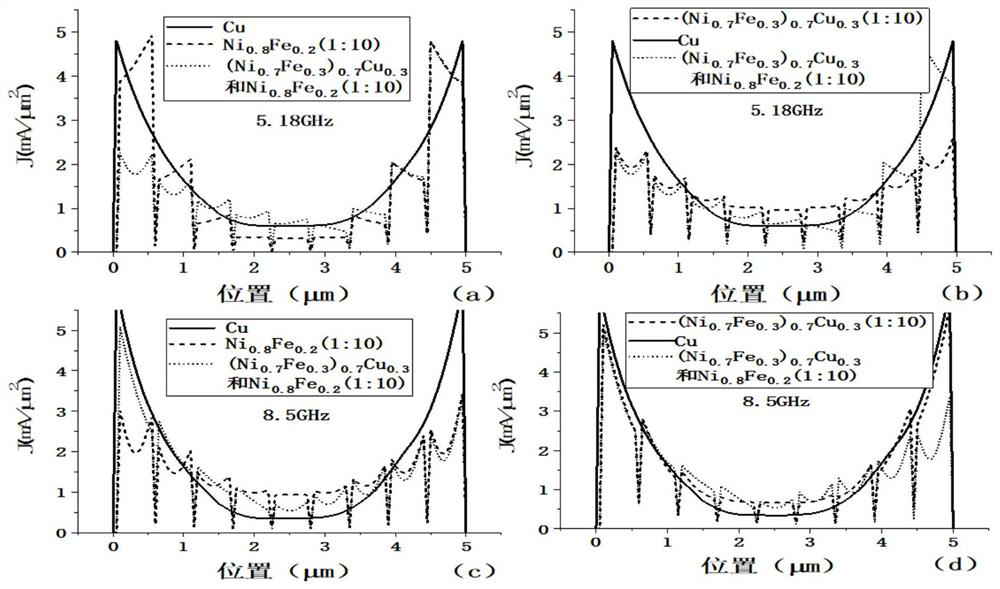

[0034] The artificial conductor structure of this embodiment is Cu / (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 / Cu / (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 / Cu / (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 / Cu / (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu, such as figure 1 shown. Among them, the Cu layer thickness is 500nm, the ferromagnetic layer thickness is 50nm (Cu has 9 layers, (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 and Ni 0.8 Fe 0.2 4 layers each), with a total thickness of 4.9 μm. Among them, (Ni 0.7 Fe 0.3 ) 0.7 Cu 0.3 The magnetic film has low coercive force (Hce=3.26Oe, Hch=2.15Oe), natural resonance frequency is 491.1MHz, dynamic saturation magnetization is 5.77kGs, and damping factor is 0.026.

[0035] The structural parameters of the coplanar waveguide are set as follows: the base material is high-resistance silicon, the thickness is 0.15 mm, the width of the central conduction band is 15 μm, the total thickness of the conductor i...

Embodiment 2

[0044] Compared with Embodiment 1, this embodiment differs in that: the artificial conductor structure is Cu / Ni from top to bottom 0.45 Fe 0.55 / Cu / Ni 0.45 Fe 0.55 / Cu / Ni 0.45 Fe 0.55 / Cu / Ni 0.45 Fe 0.55 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu / Ni 0.8 Fe 0.2 / Cu, wherein, the Cu layer thickness is 500nm, the ferromagnetic layer thickness is 50nm (Cu has 9 layers, Ni 0.45 Fe 0.55 and Ni 0.8 Fe 0.2 4 layers each), with a total thickness of 4.9 μm. For Ni in the second half 0.8 Fe 0.2 , the compensation frequency point under this structure is 8.5GHz, and for the upper part of Ni 0.45 Fe 0.55 , the compensation frequency point is 14.3GHz.

[0045] Figure 5 The artificial conductor (Ni 0.45 Fe 0.55 and Ni 0.8 Fe 0.2 ) of the resistance value as a function of frequency, and compared it with a pure copper wire (Cu), using a ferromagnetic material as the magnetic layer (Ni 0.8 Fe 0.2 ), using a ferromagnetic material as the magnetic layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com