Firefighting pipe paint spraying device

A technology for fire-fighting pipes and fixtures, applied in spraying devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low efficiency, human health injury, unacceptable production scale factories, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

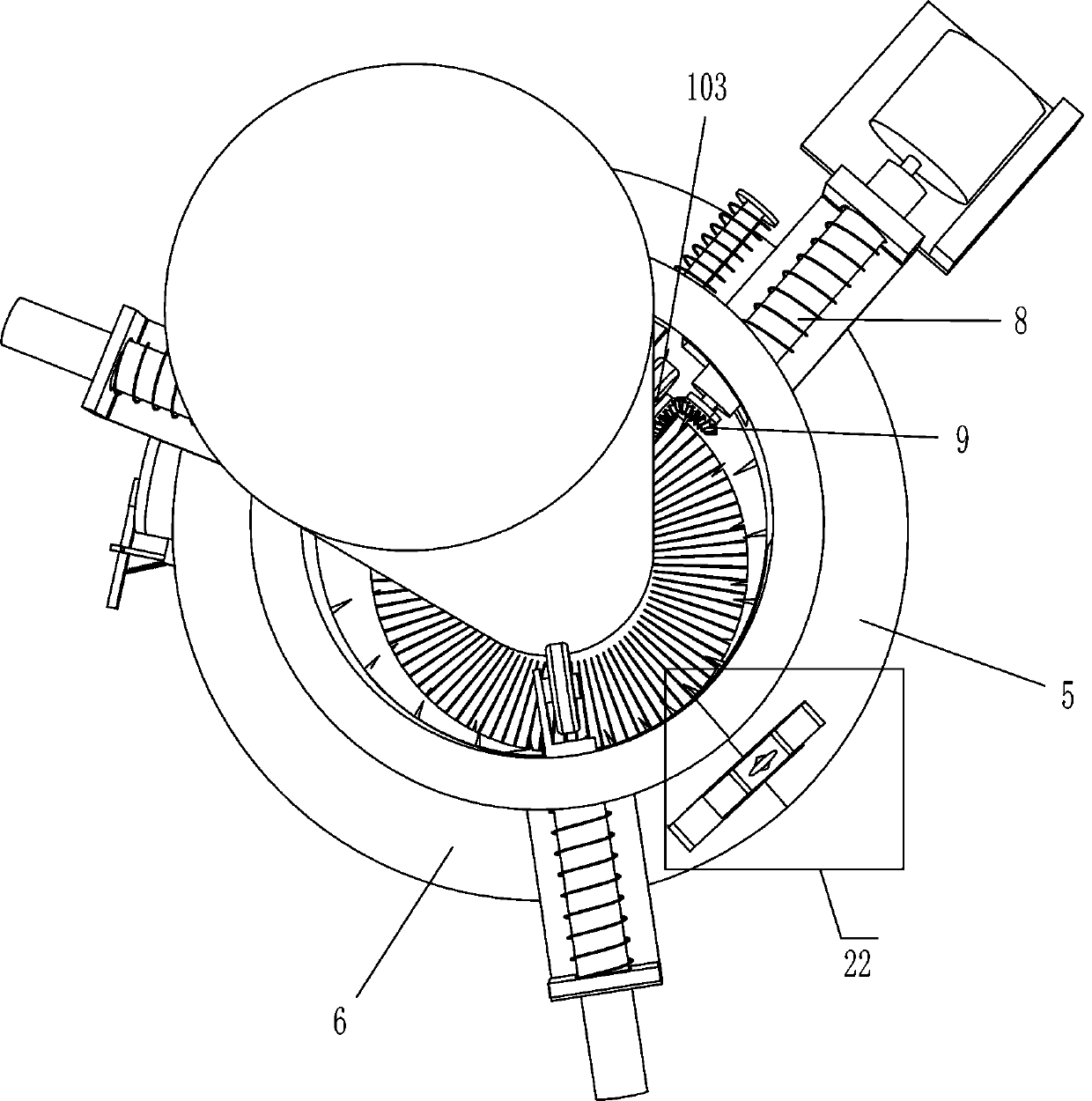

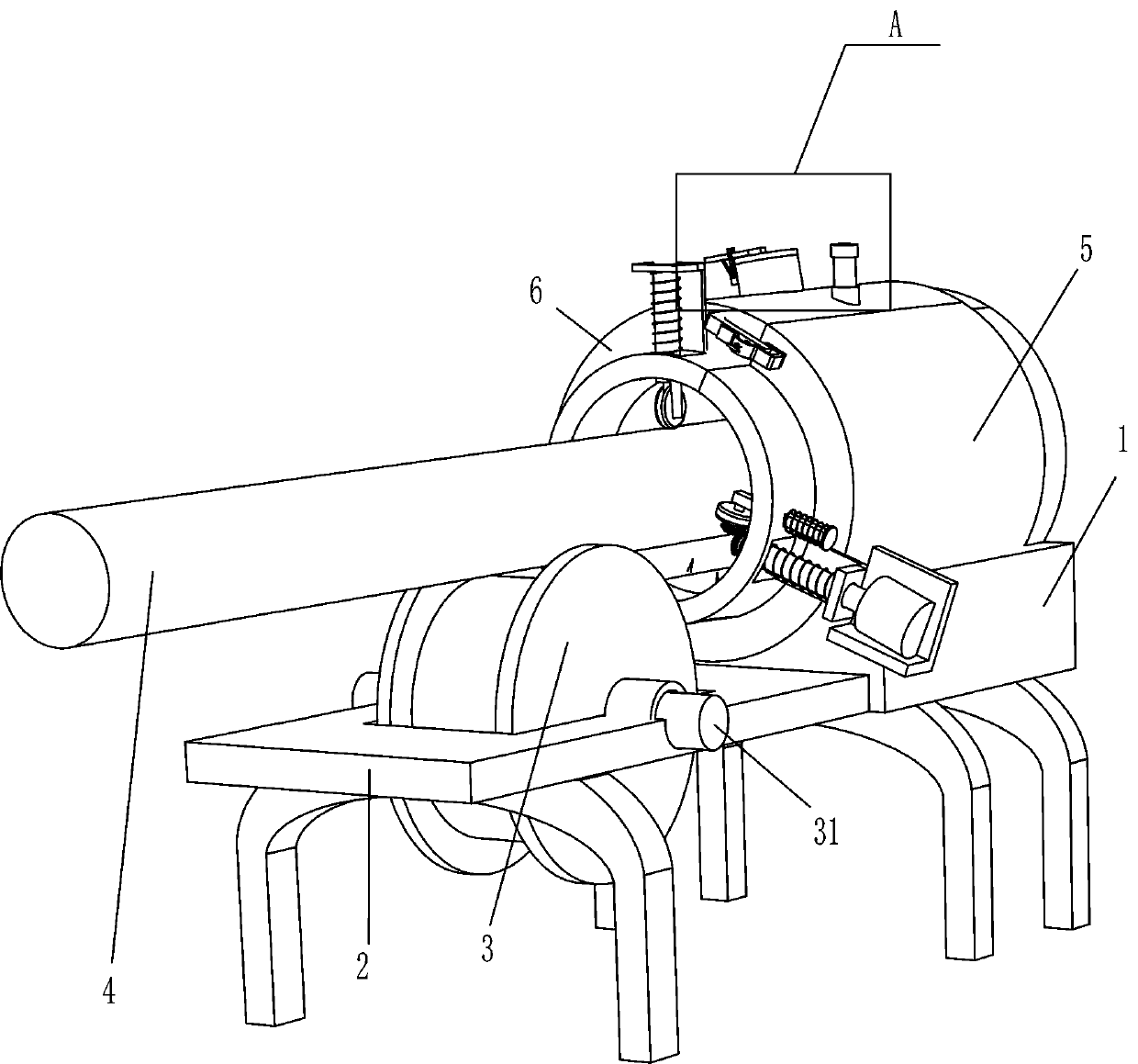

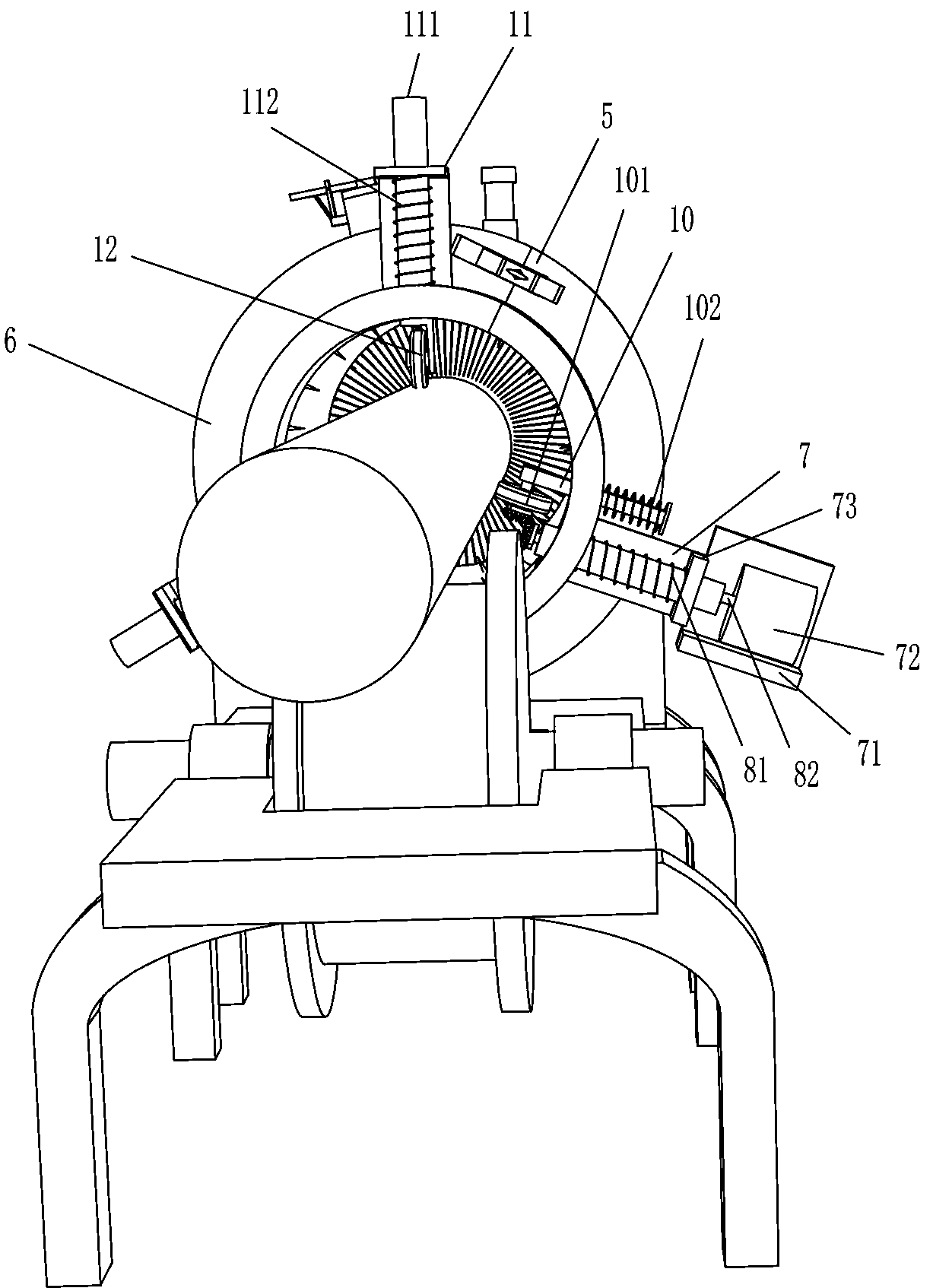

[0060] A fire pipe painting device, such as Figure 1-2As shown, include support 1, push frame 2, sliding wheel 3, rolling shaft 31, shell assembly one 5, shell assembly two 6, support frame one 7, support frame two 71, motor 72, support frame three 73, Guide rod 8, compression spring 81, rotating shaft 82, bevel gear 9, wheel support rod 10, transmission wheel 101, coil spring 102, transmission connecting shaft 103, supporting device, feeding device and fixing device 22, push frame 2 are fixed on On the front side above the bracket 1, the rolling shaft 31 is rotatably connected between the left and right side walls in the push frame 2, the sliding wheel 3 is fixedly connected to the rolling shaft 31, and the shell assembly one 5 and the shell assembly two 6 are two semicircular structures , and form a circle after being combined, the shell assembly one 5 and the shell assembly two 6 are movably arranged at the upper rear part of the bracket 1, the support frame one 7 is fixed...

Embodiment 2

[0063] On the basis of Example 1, such as Figure 1-6 As shown, the support device includes a support plate 11, a slide bar 111, a telescopic spring 112 and auxiliary wheels 12, and the two support plates 11 are affixed to the upper and lower sides of the outer shell assembly two 6, and the outer sides of the two support plates 11 are Vertically slidingly connected with a slide bar 111, the inner end of the slide bar 111 slides through the shell assembly 26, the telescopic spring 112 is wound on the slide bar 111, one end of the telescopic spring 112 is connected to the support plate 11, and the other end is connected to the slide bar 111 , the inner end of the slide bar 111 is equipped with auxiliary wheels 12 .

[0064] When the fire-fighting pipeline 4 is in contact with the auxiliary wheels 12, the fire-fighting pipeline 4 pushes the auxiliary wheels 12 to drive the slide bar 111 to move outward. At the same time, the telescopic spring 112 is compressed. The auxiliary whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com