Connecting structure of inner end cover and reel pipe end socket and object shielding curtain

A technology of connecting structure and inner end cover, applied in the field of blinds, can solve the problems of abnormal noise caused by pulling, using abnormal noise, and the difficulty of the blinds to meet the requirements of automobile manufacturers, so as to eliminate the abnormal noise and reduce the area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

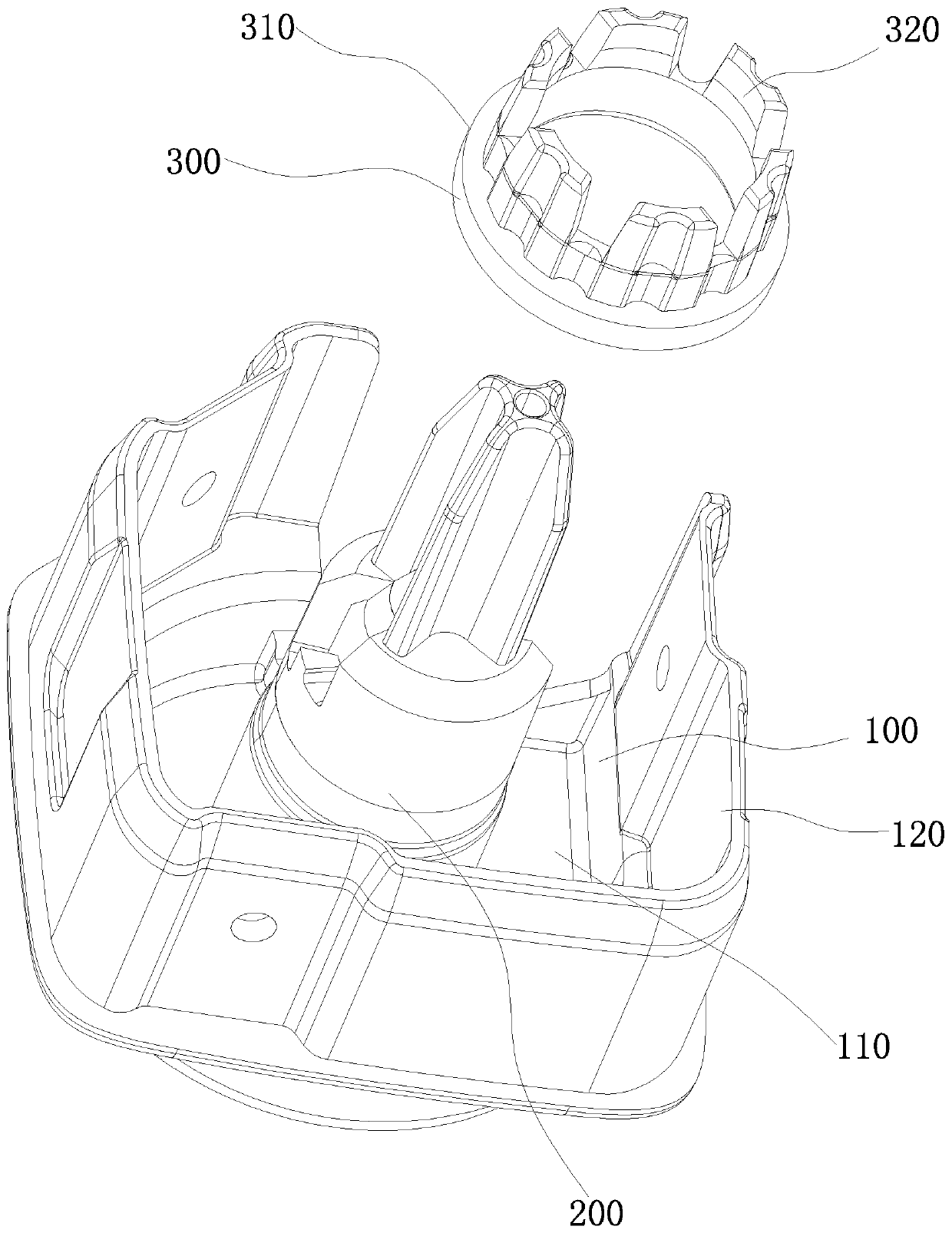

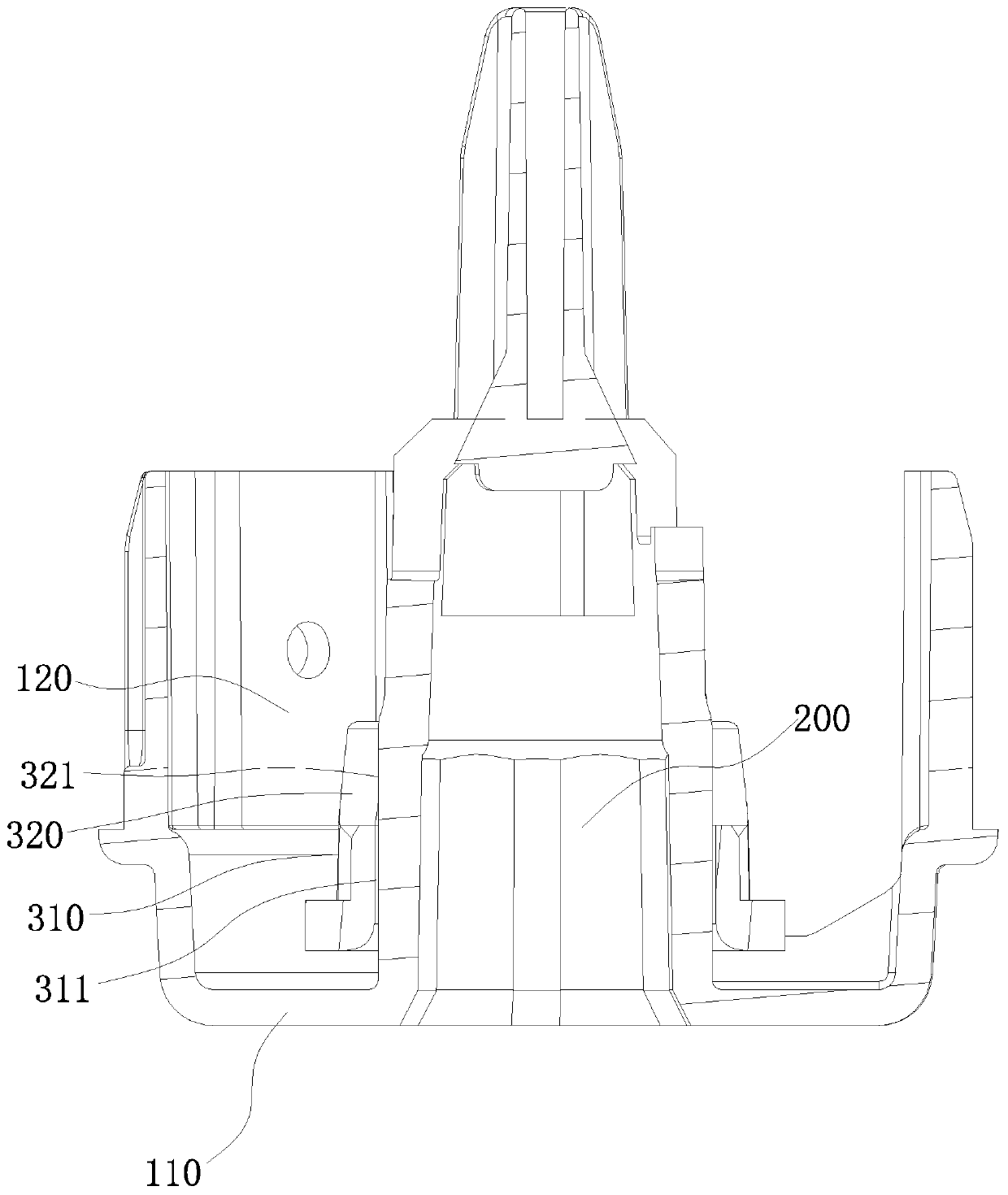

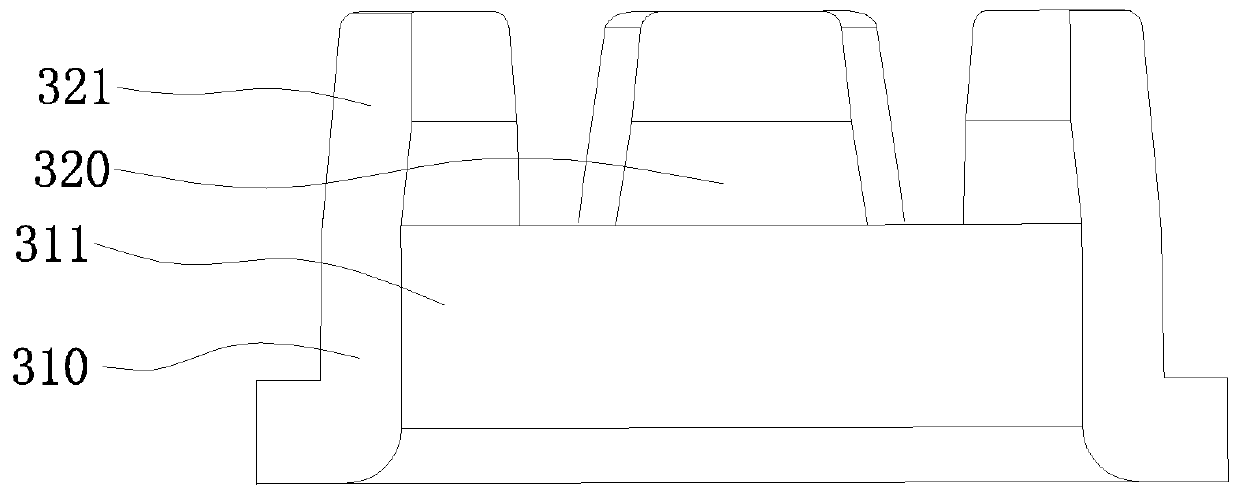

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 As shown, a connection structure between an inner end cap and a coiled tube head includes: an inner end cover 100 and a coiled tube head 300, wherein the coiled tube head 300 is arranged on the inner end cap 100 and is used to seal At the end of the shade roller tube 400 .

[0035] It is worth noting here that the existing vehicle blinds will produce abnormal noise when pulled. The length of the contact surface formed between the outer peripheral surfaces of the shaft is generally about 10mm, that is, the axial length of the head is generally about 10mm, and the assembly gap between the head and the shaft body is guaranteed to be within 0.1-0.2mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com