Method for modifying stabilization treatment process of septic tank

A stabilization treatment, septic tank technology, applied in biological sludge treatment and other directions, can solve the problem of ineffective sludge conversion, and achieve the effect of reducing construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

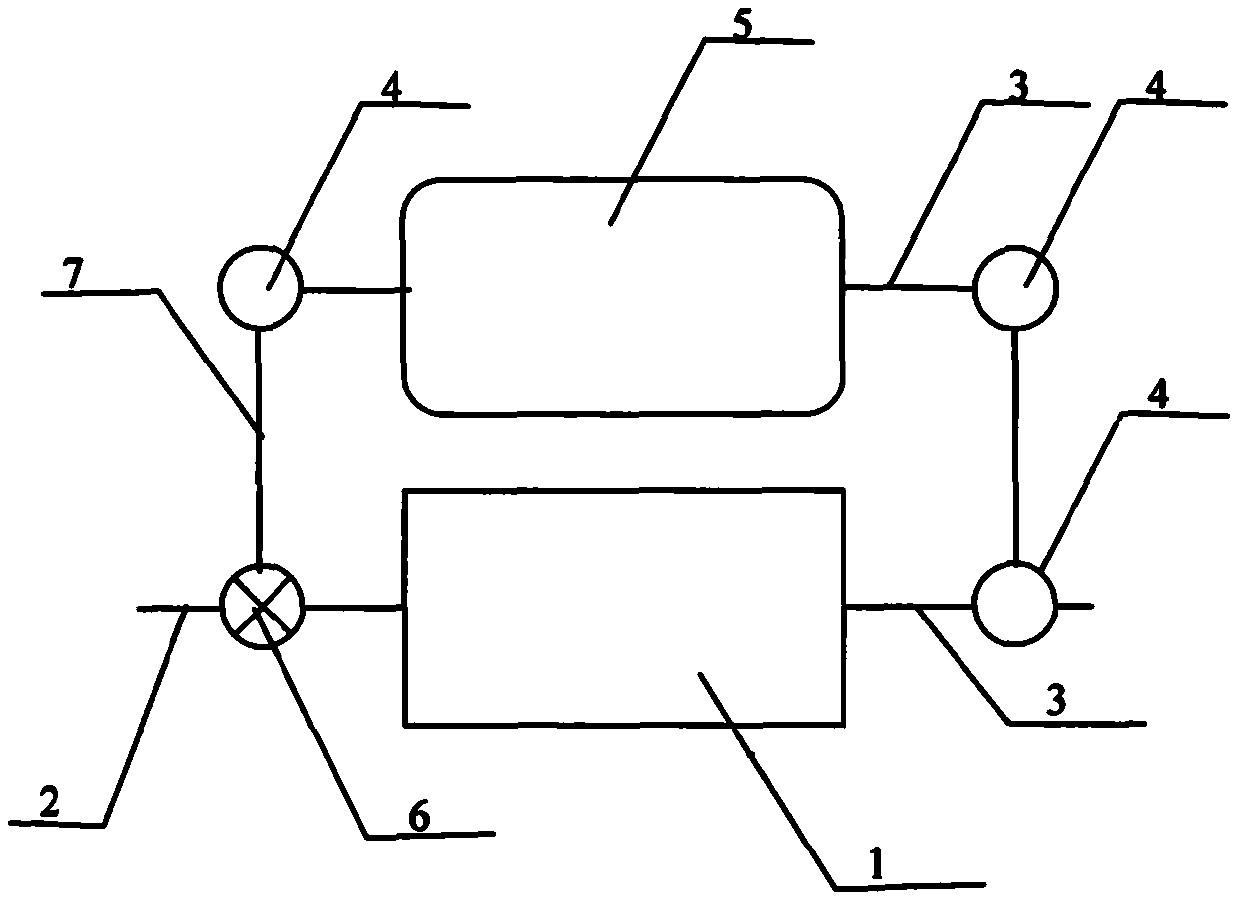

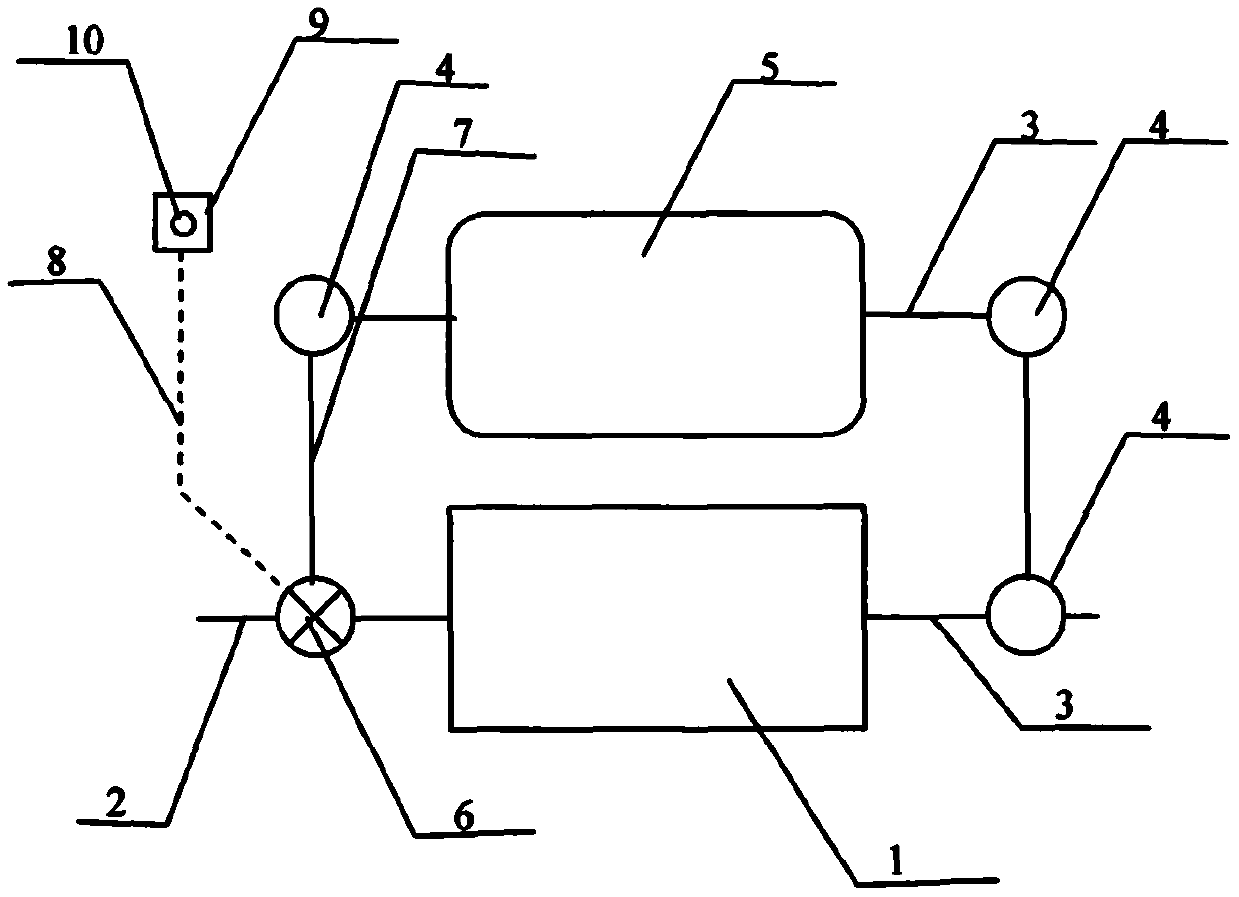

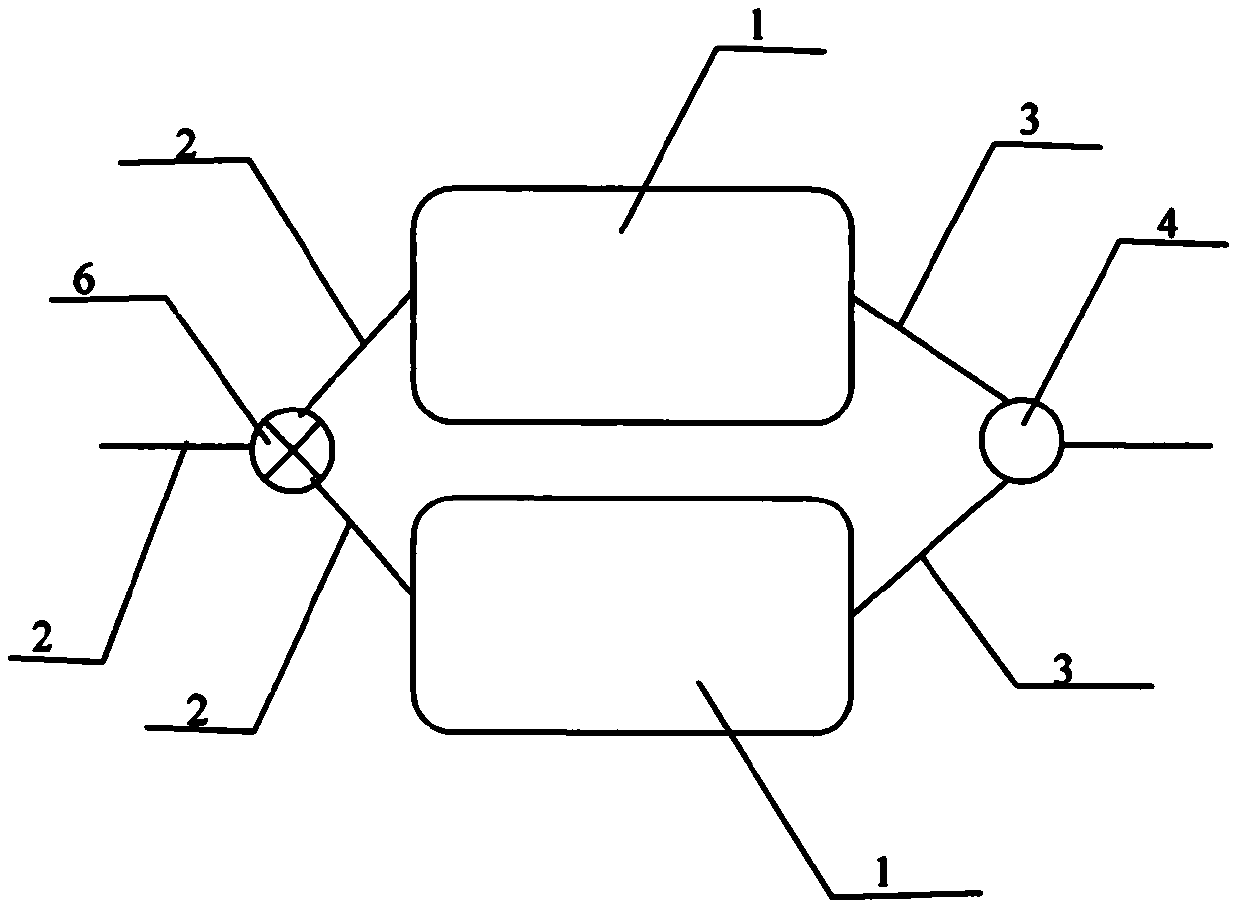

[0014] like figure 1 The shown embodiment 1 is to build a parallel newly-built septic tank 5 outside the original septic tank 1, and build a water diversion diversion well 6 on the sewage pipe 2 before the original septic tank 1, from which the water diversion diversion The flow well 6 leads to a bypass sewage pipe 7, and the bypass sewage pipe 7 passes through the inspection well 4 and changes direction to lead into the newly-built septic tank 5, and the waste discharge pipe 3 drawn from the newly-built septic tank 5 passes through the inspection well 4 and is connected with the original septic tank. The sewage pipes 3 from the pool 1 are combined, and the diversion well is used to control the sewage and feces to alternately enter the original septic tank 1 and the new septic tank 5. One of the septic tanks receives and accumulates feces, and the other septic tank After the manure is stabilized, the two septic tanks are controlled to exchange for manure storage and manure sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com