Coal gasification method and device employing plasma torch heating technology

A technology of plasma torch and coal gasification, which is applied in the field of coal gasification, can solve problems such as the limited range of raw coal, the limited range of raw coal selection, and pressure mismatch, and achieve the effects of simple structure, high temperature, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

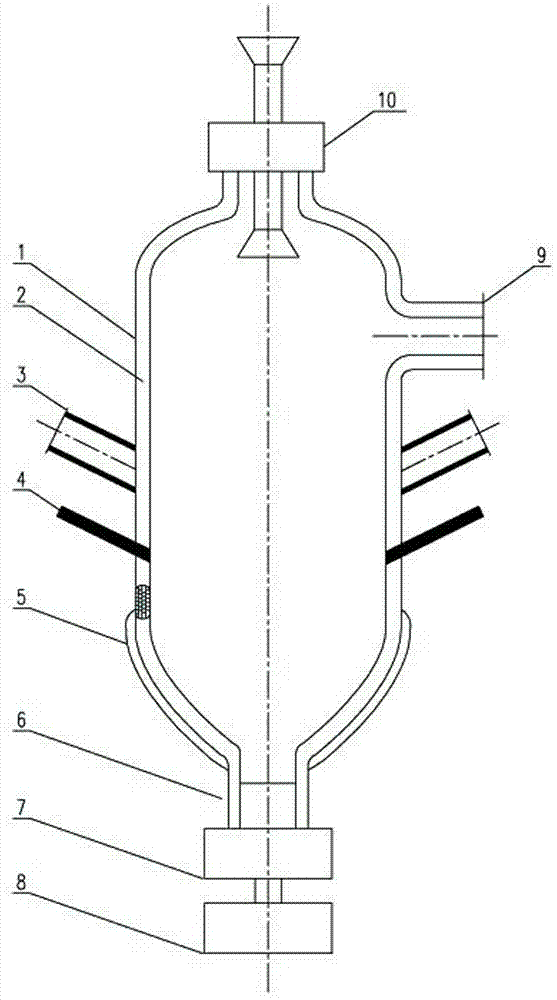

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

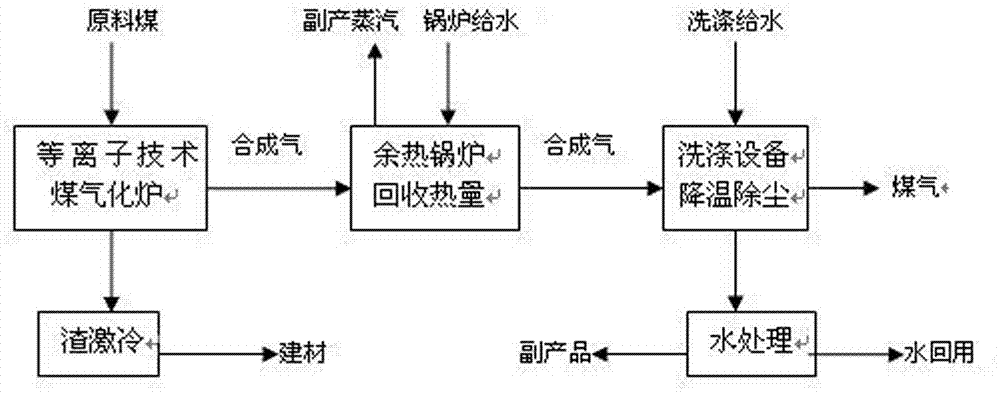

[0024] The invention provides a coal gasification method and device using plasma torch heating technology, comprising the following steps:

[0025] 1. Raw coal preparation and adding raw coal to the special structure plasma technology coal gasifier through automatic feeding system; raw coal can include coal with high ash content and high melting point, as well as viscous bituminous coal and sub-bituminous coal, etc.; raw coal should be Maintain a certain particle size range (crushed coal > 3mm, pulverized coal content < 10%).

[0026] 2. The raw coal is gasified in the coal gasifier. The innovative gasification technology is a combination of traditional atmospheric pressure fixed layer gasification and modern high temperature slag gasifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com