Telescopic conveyor

A conveyor, telescopic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as jamming, pushing or jumping away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

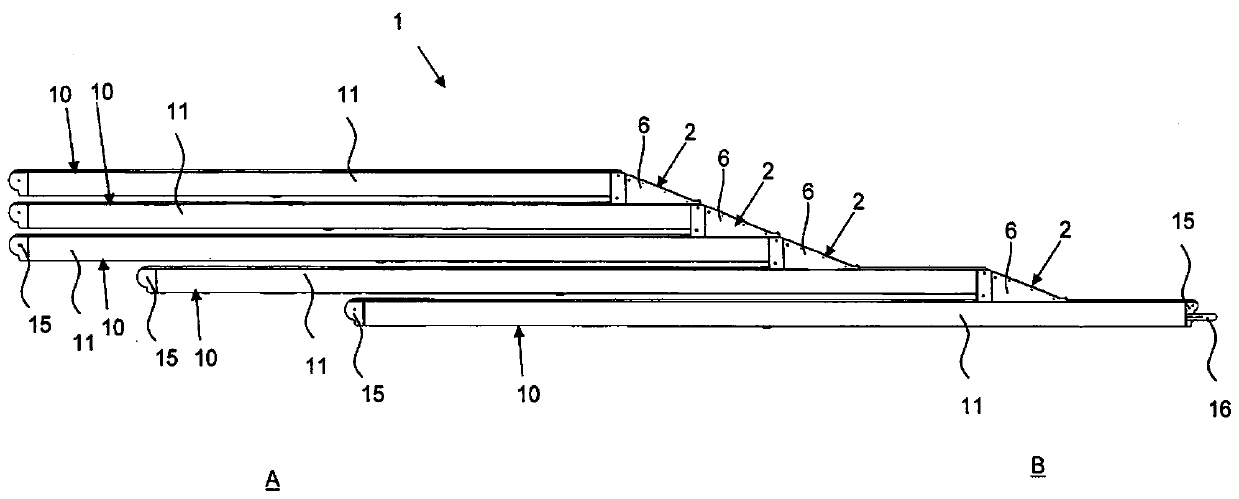

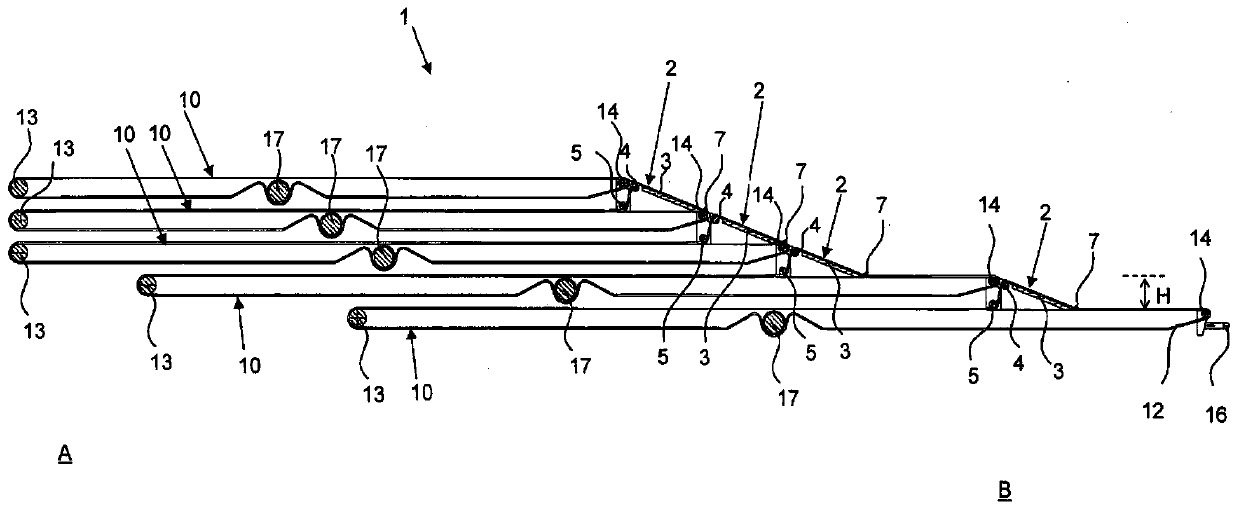

[0038] The device according to the invention relates to a telescopic conveyor in which the difference in height at the transfer end between two directly superimposed and thus adjacent conveyor belts is overcome by bridging means without adjoining edges, so that Conveying objects or small and angular objects of almost any size, shape and made of elastic material can be transported from the lower conveyor belt to the upper conveyor belt or vice versa without disturbance or at least with very little disturbance.

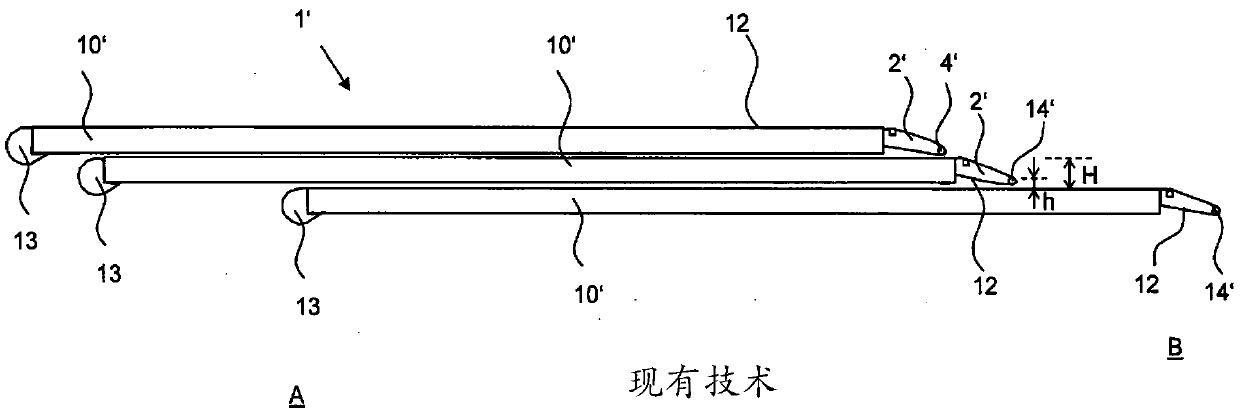

[0039] figure 1 A telescopic conveyor 1' from the prior art is shown. In this example, the telescopic conveyor 1 ′ has three conveyor belts 10 ′, which are arranged one above the other and overlapped. The telescopic conveyor 1' is variable in length and is adjusted by pulling apart and pushing together conveyor belts 10' which are movable relative to each other in the longitudinal direction. To this end, each conveyor belt 10' has figure 1 Frames not represented in ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com