Patents

Literature

45results about How to "Uneven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Universal health-care board and preparation method thereof

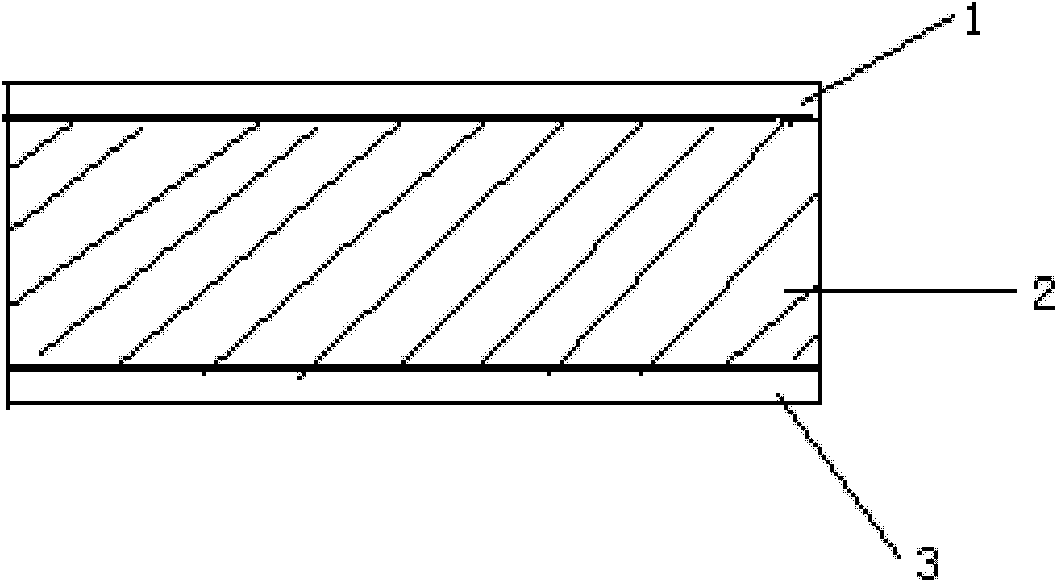

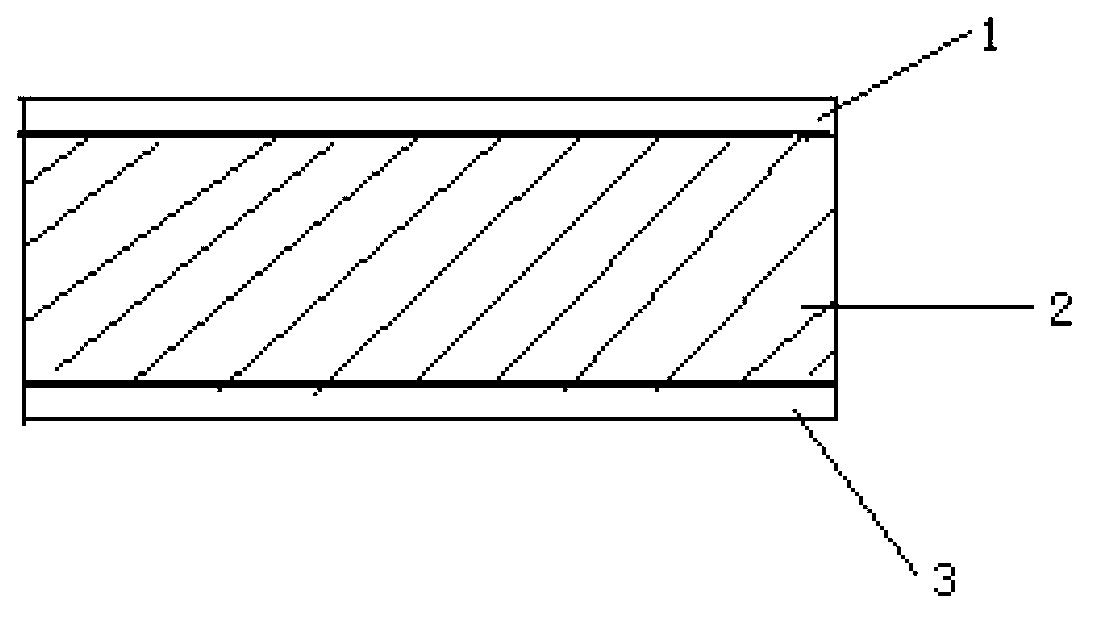

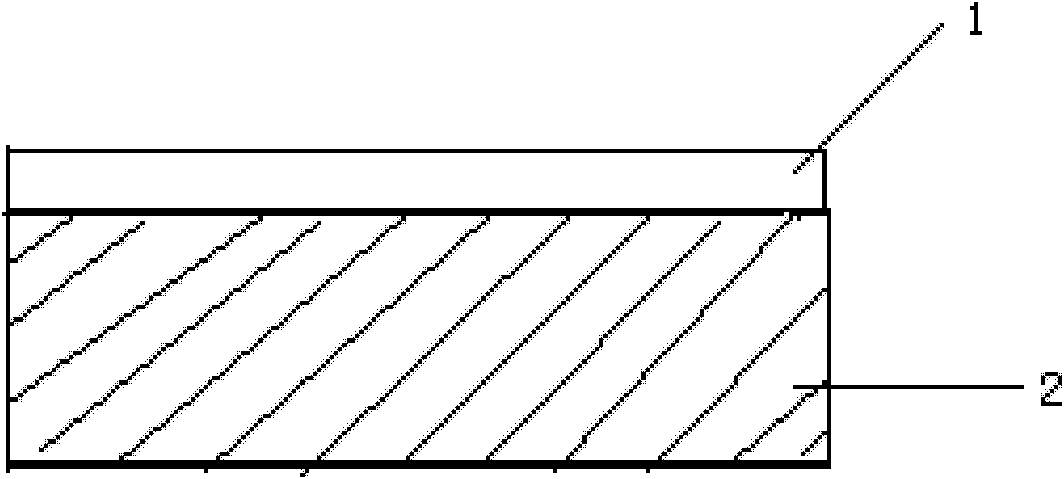

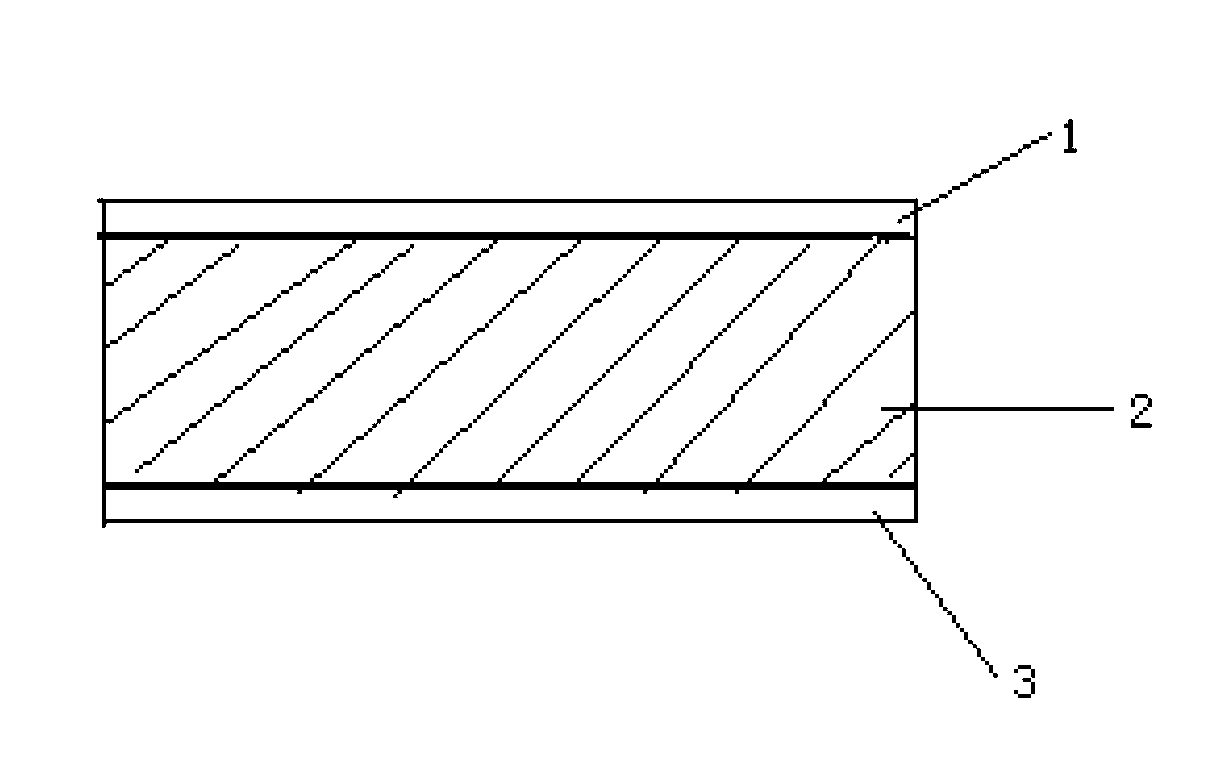

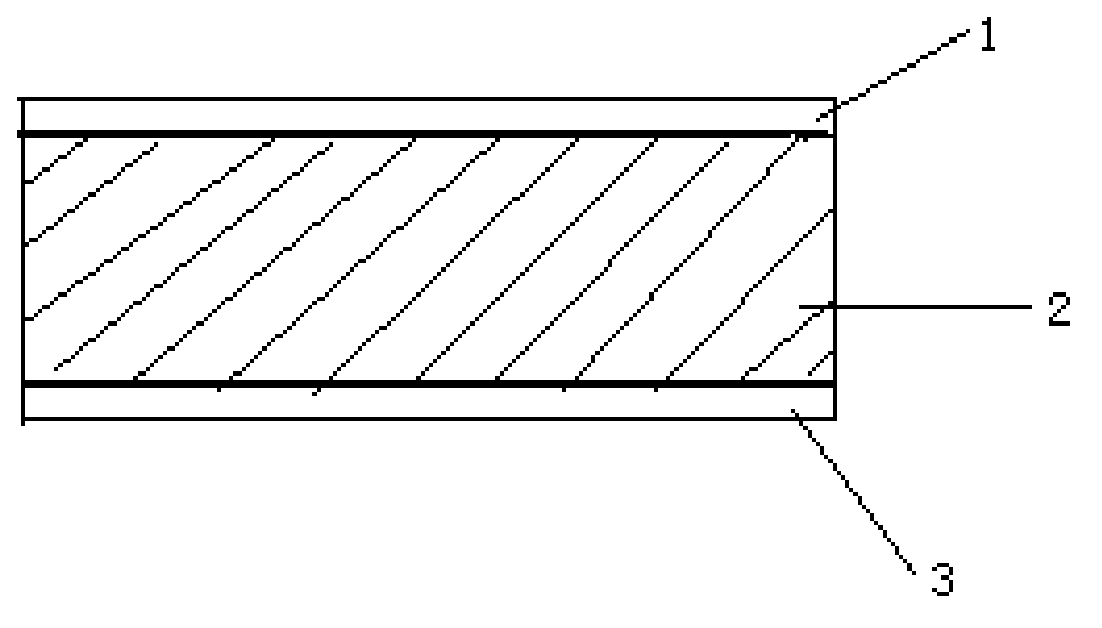

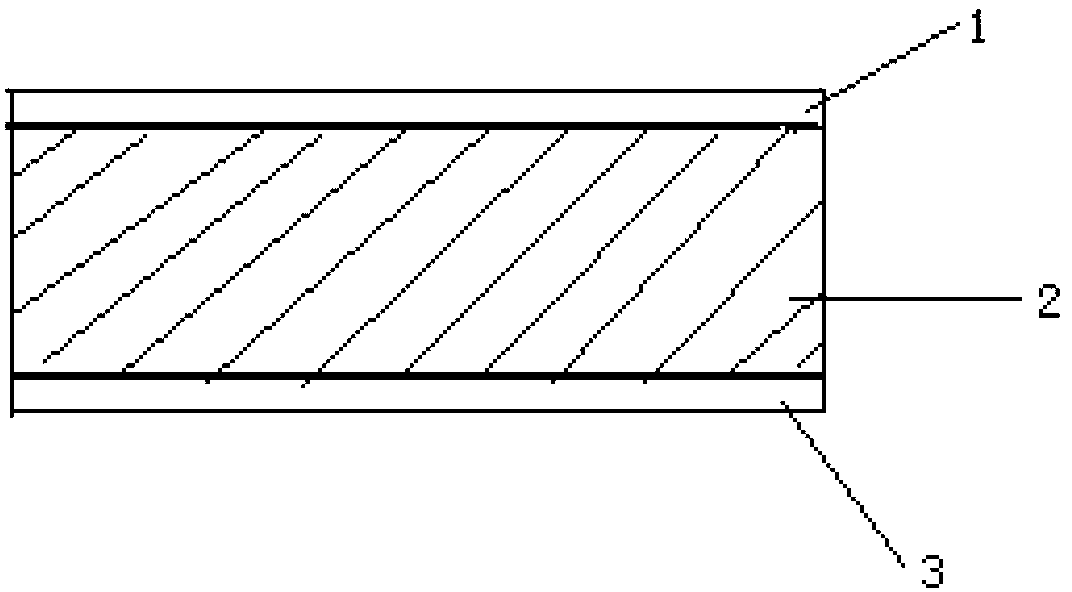

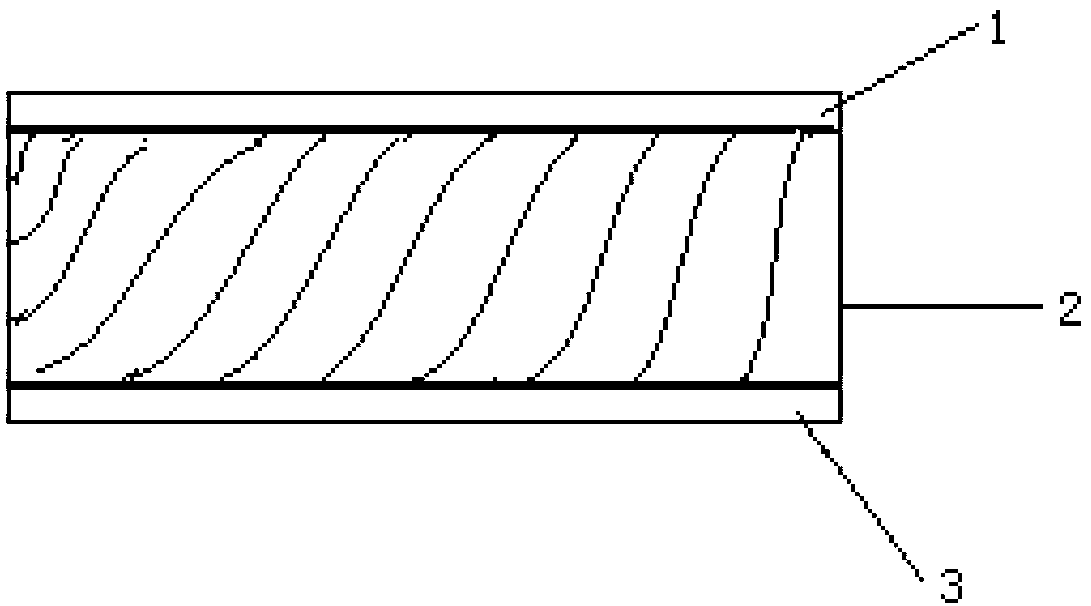

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Tatami bed core and preparation method thereof

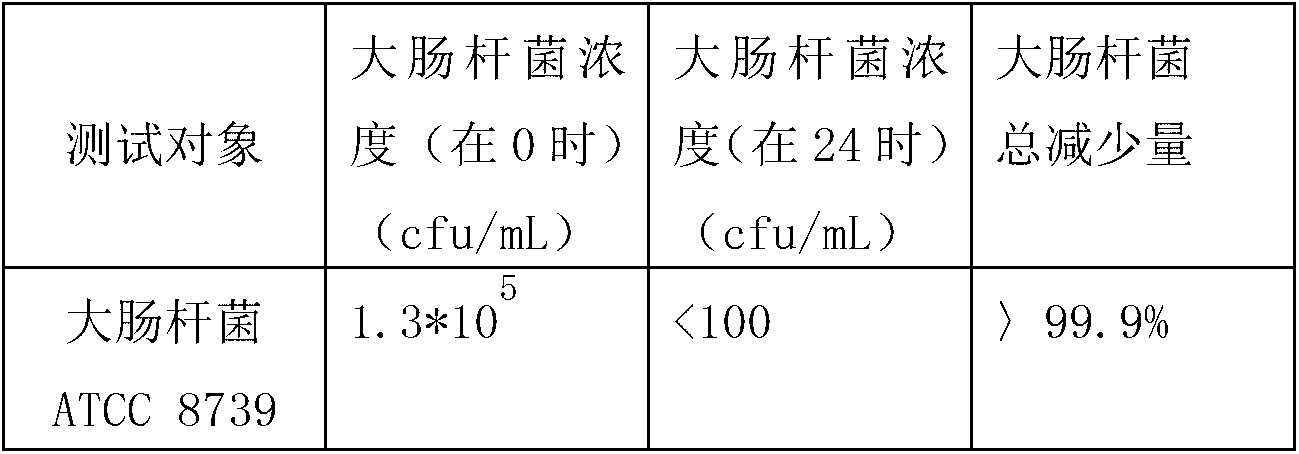

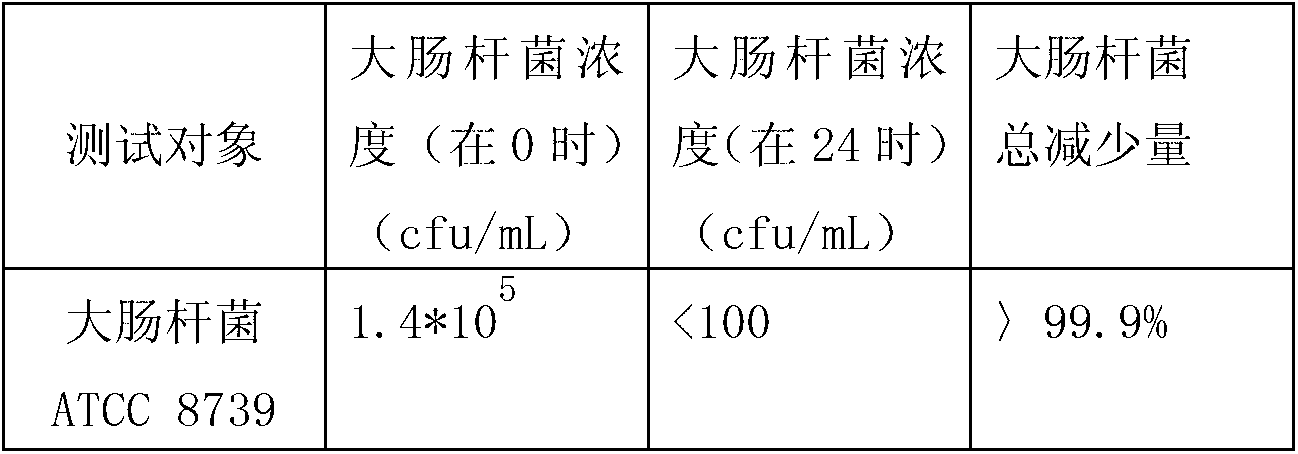

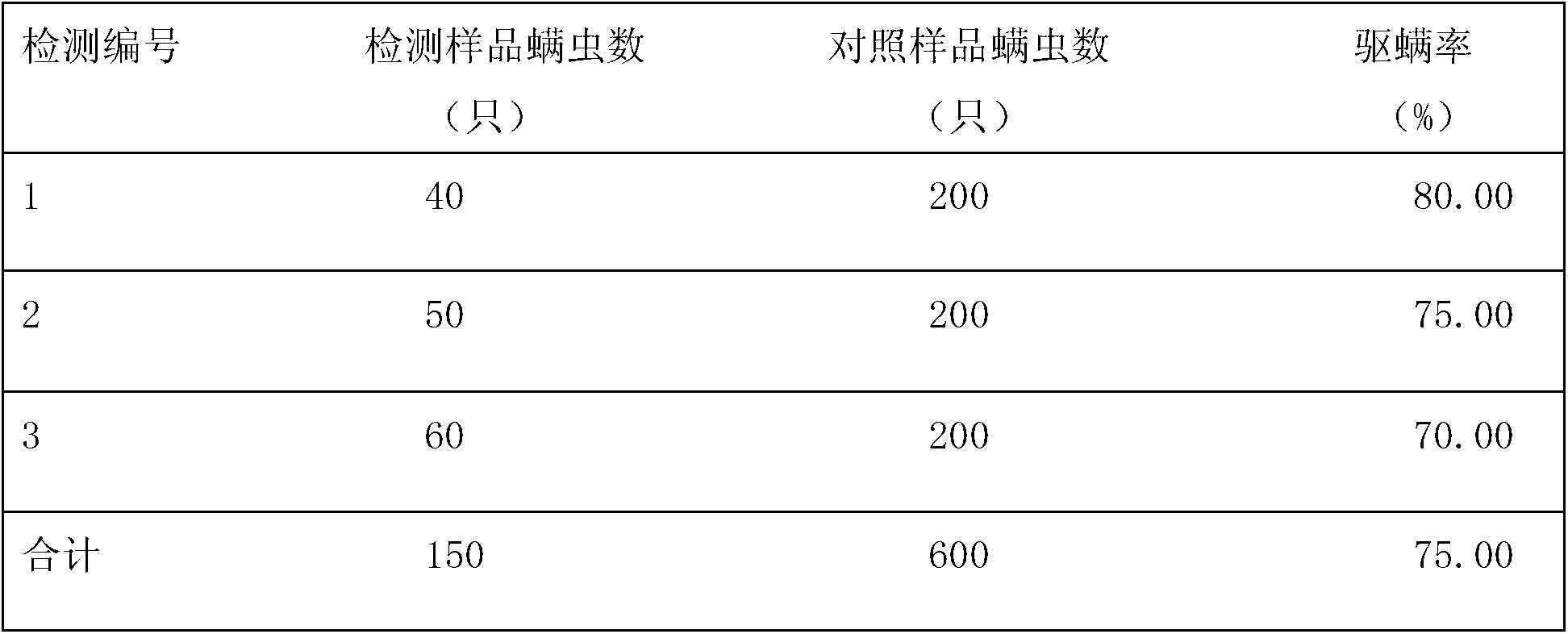

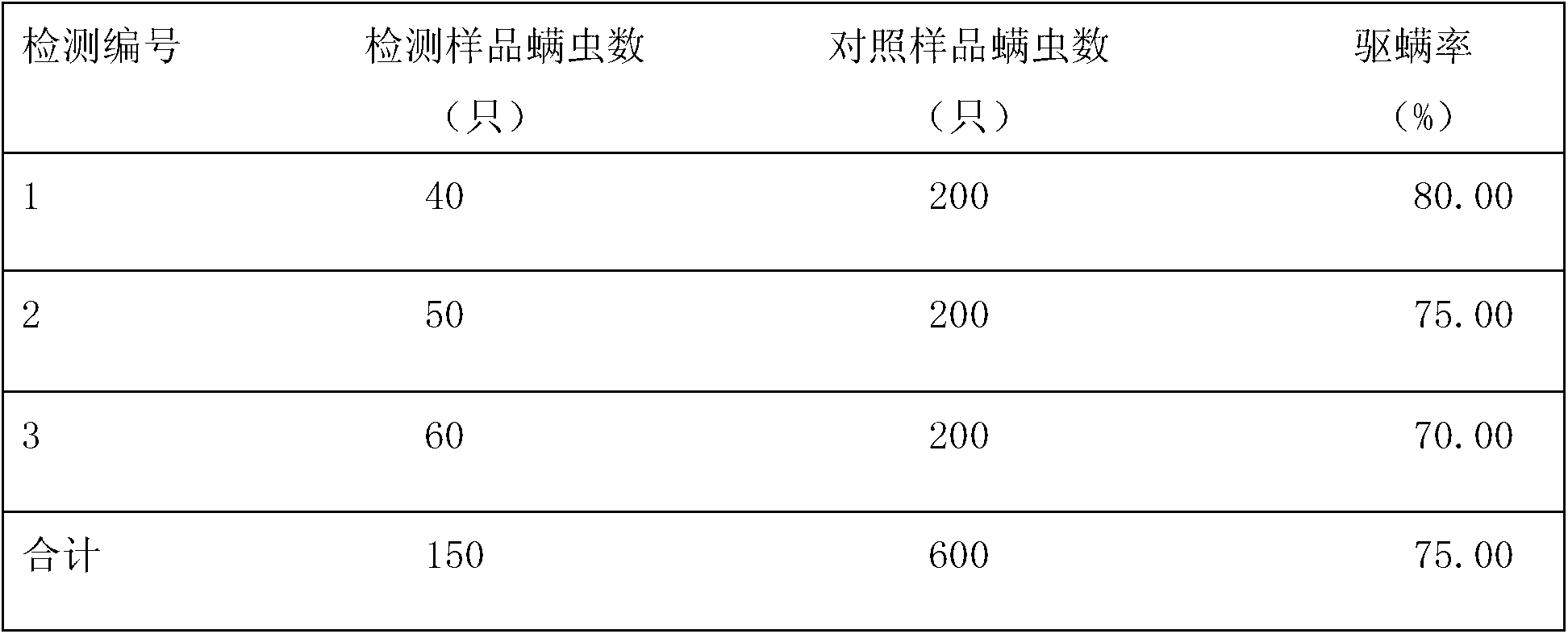

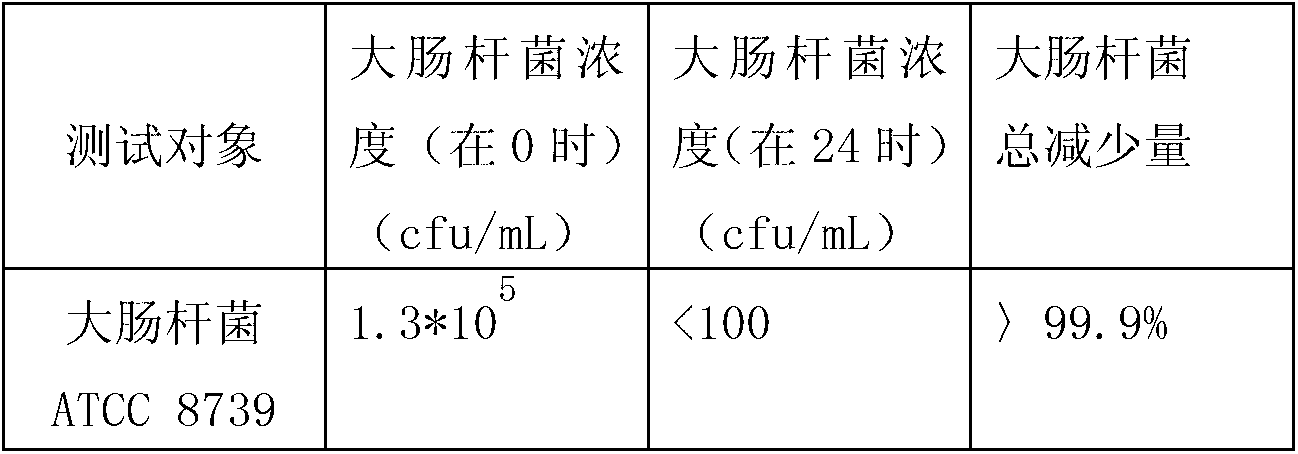

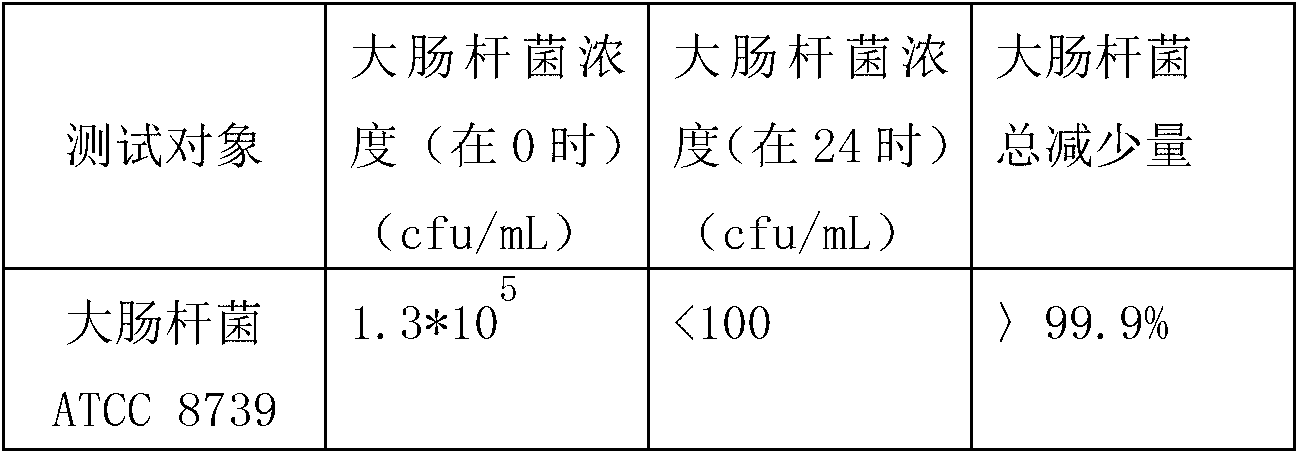

InactiveCN103054382AGood against insectsGood antibacterialStuffed mattressesSpring mattressesHemp fiberSurface layer

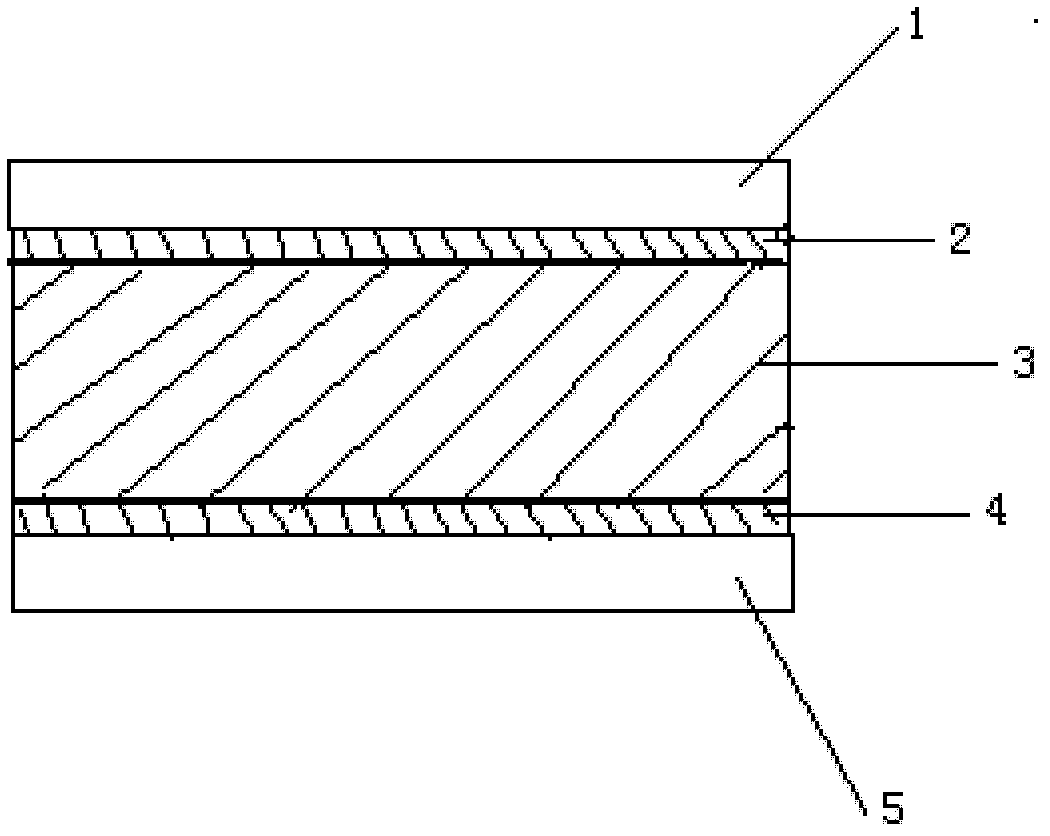

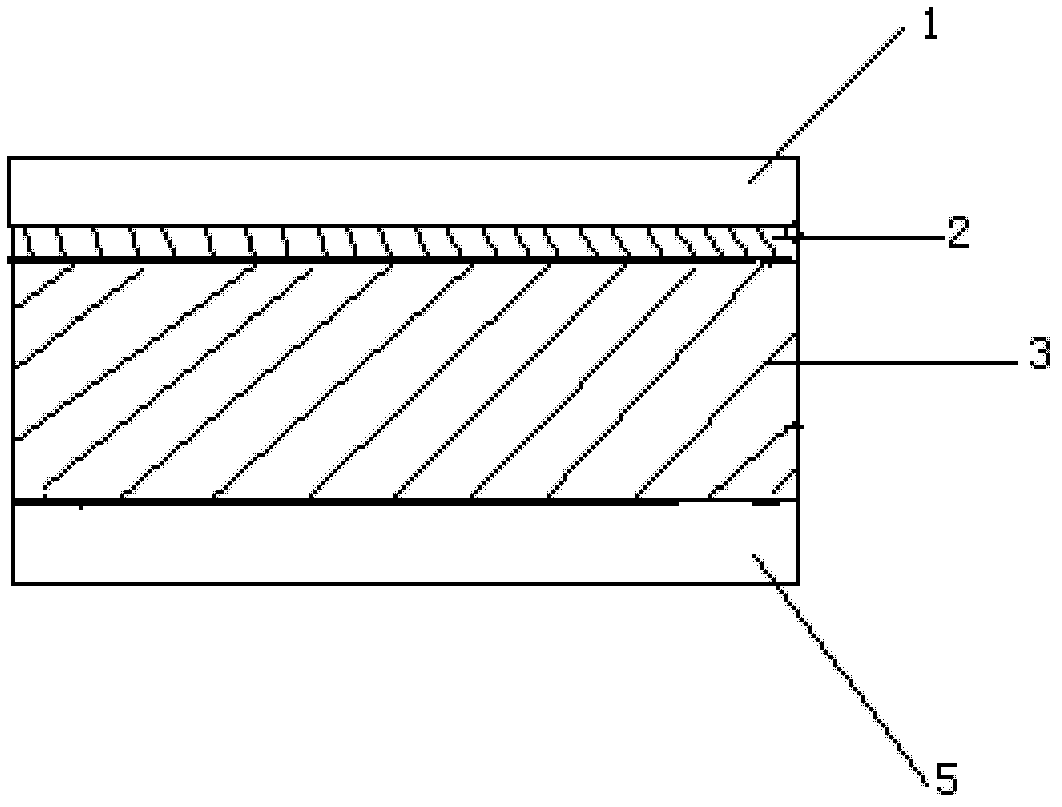

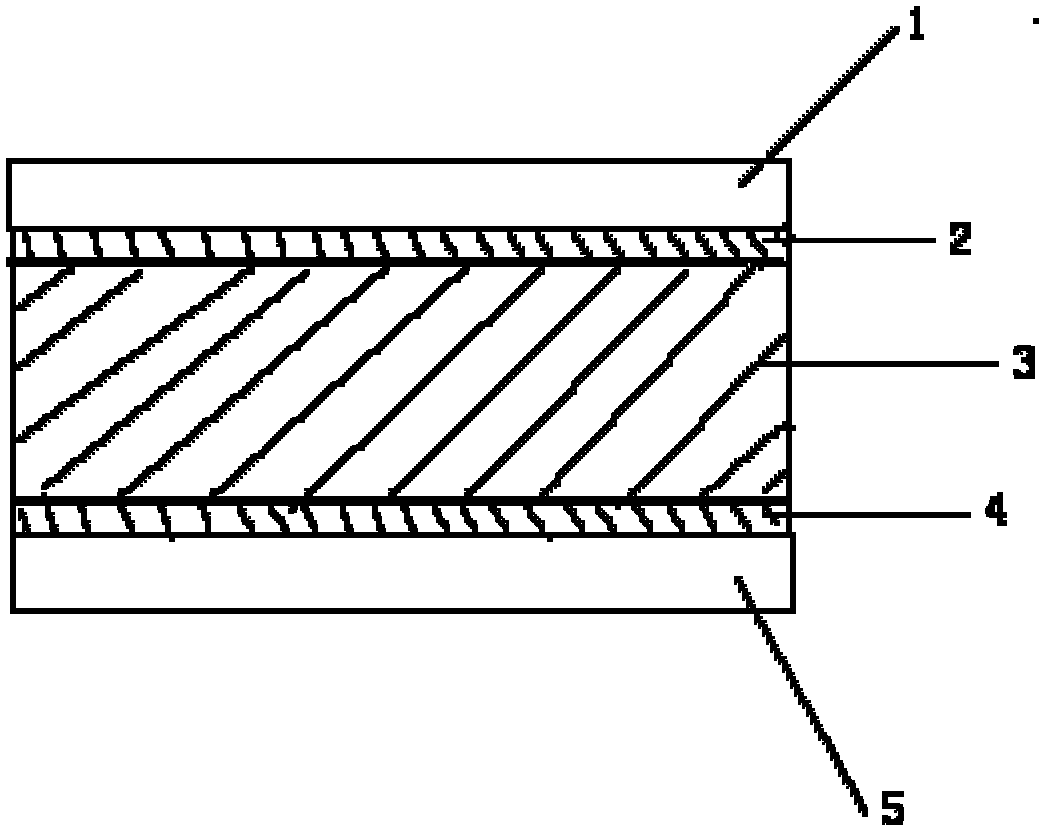

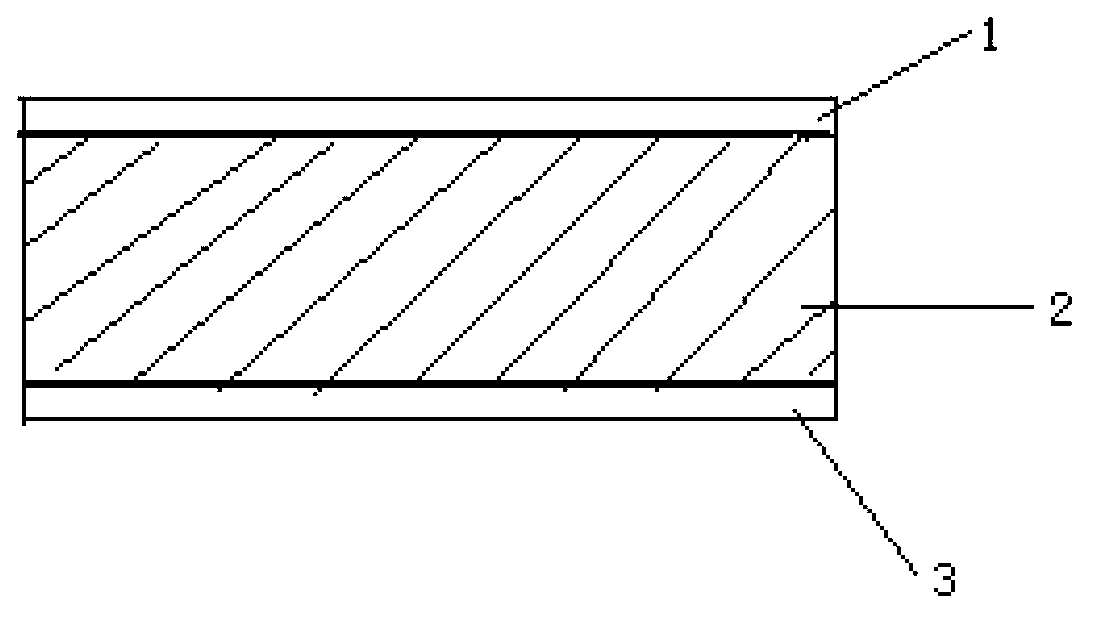

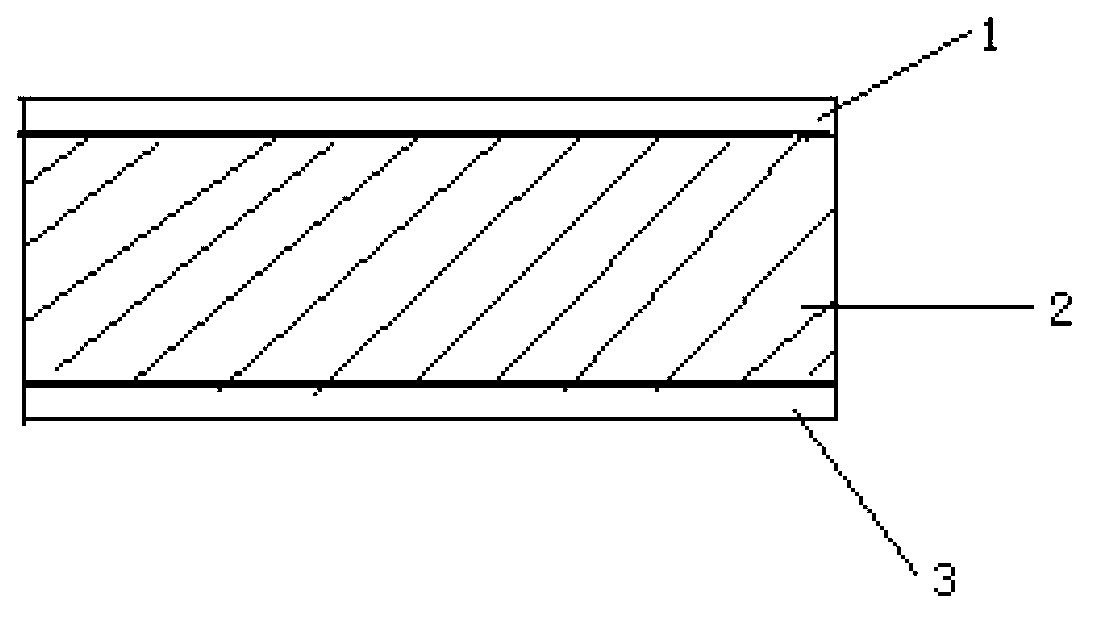

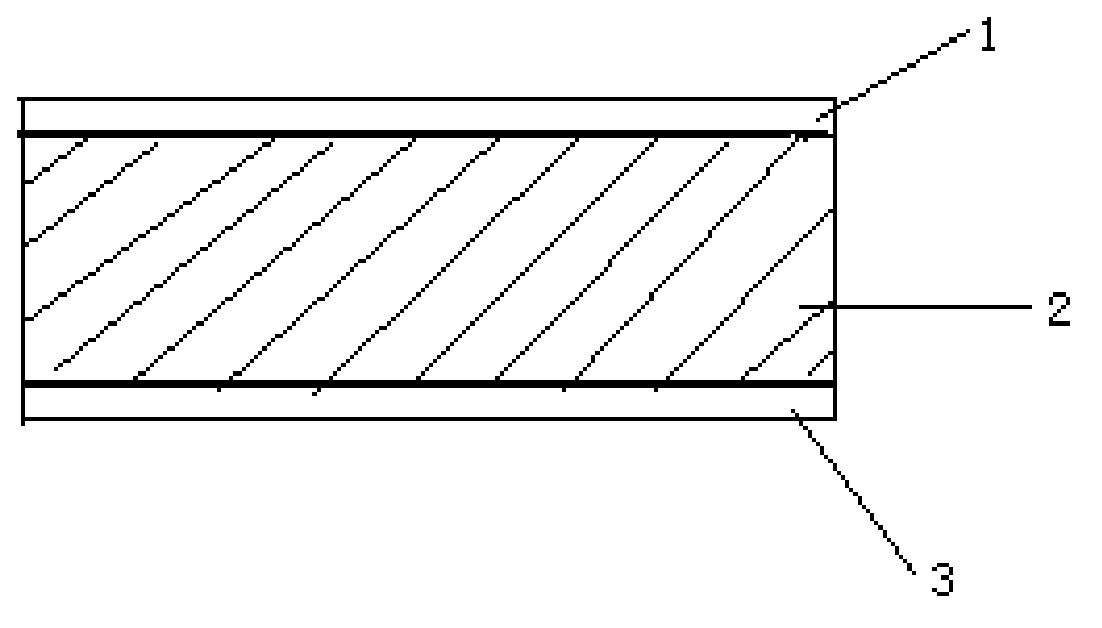

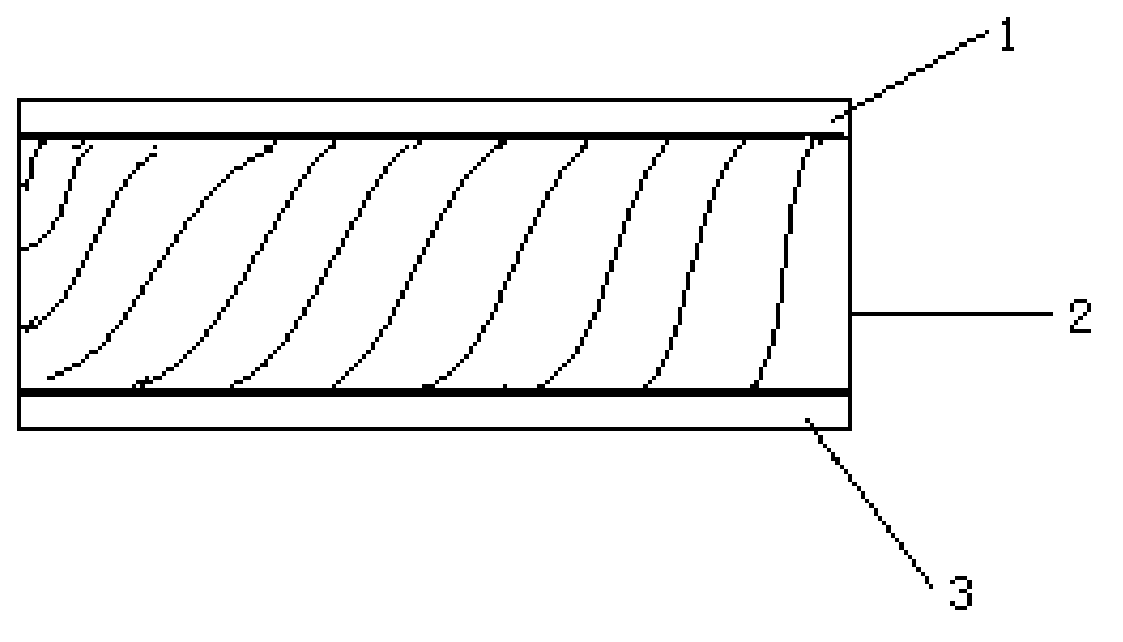

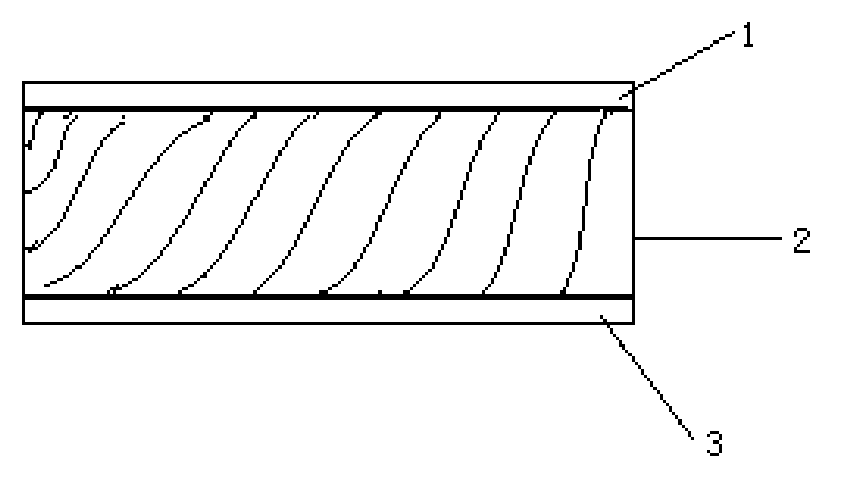

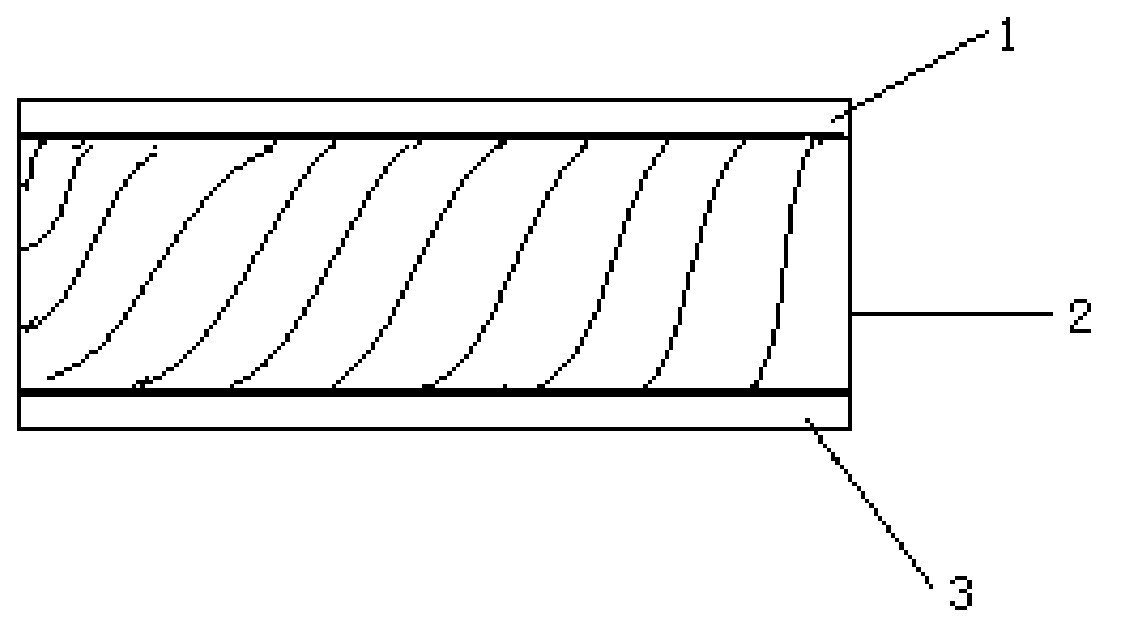

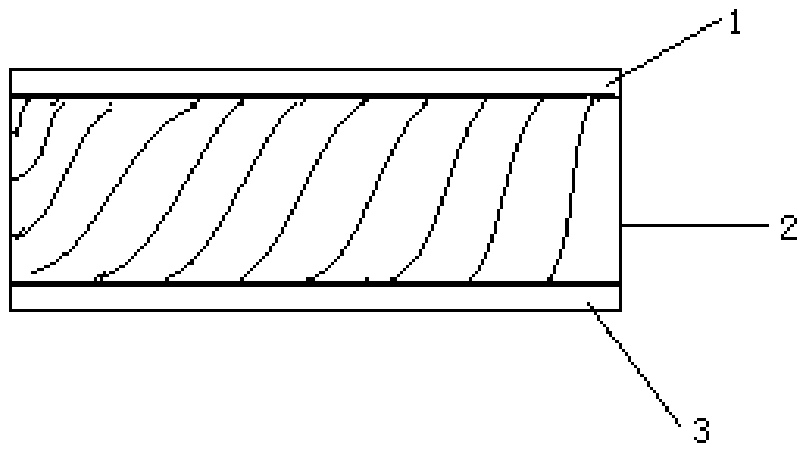

The invention discloses a tatami bed core. The tatami bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is a non-woven layer which comprises the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of raw bamboo fibers and / or hemp fibers; and the middle layer comprises the following components in percentage by weight: 5-85% of alpinia fibers, 15-40% of low melting point fibers and the balance of other fibers. The invention further discloses a preparation method of the tatami bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the tatami bed core. Through adoptions of the tatami bed core and the preparation method thereof disclosed by the invention, technical problems of mildews, insects, easiness for layering and cracking, insufficient elasticity, poor ventilating property and the like in a current bed mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

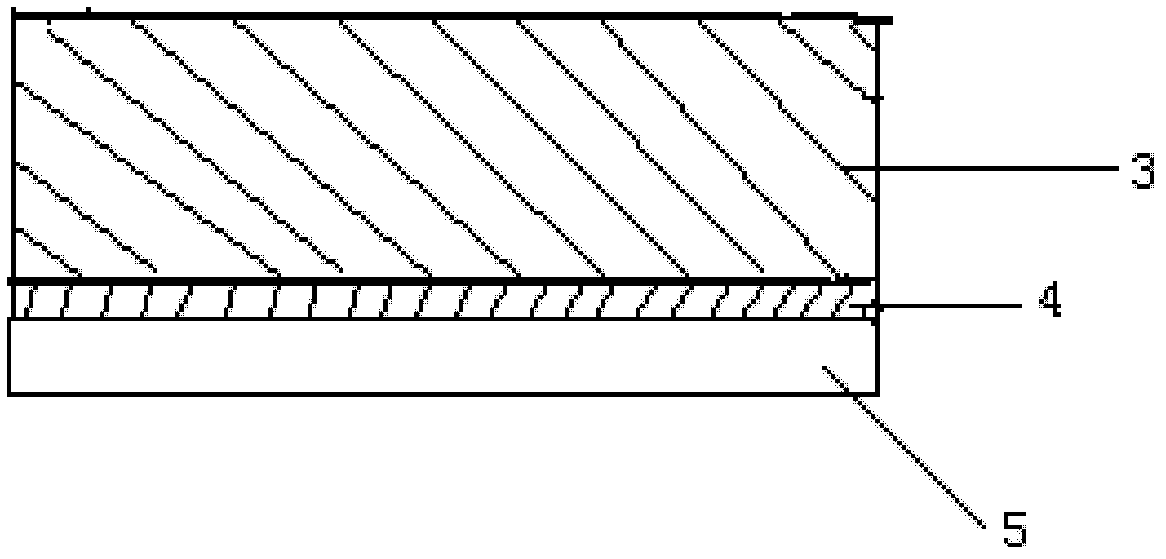

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

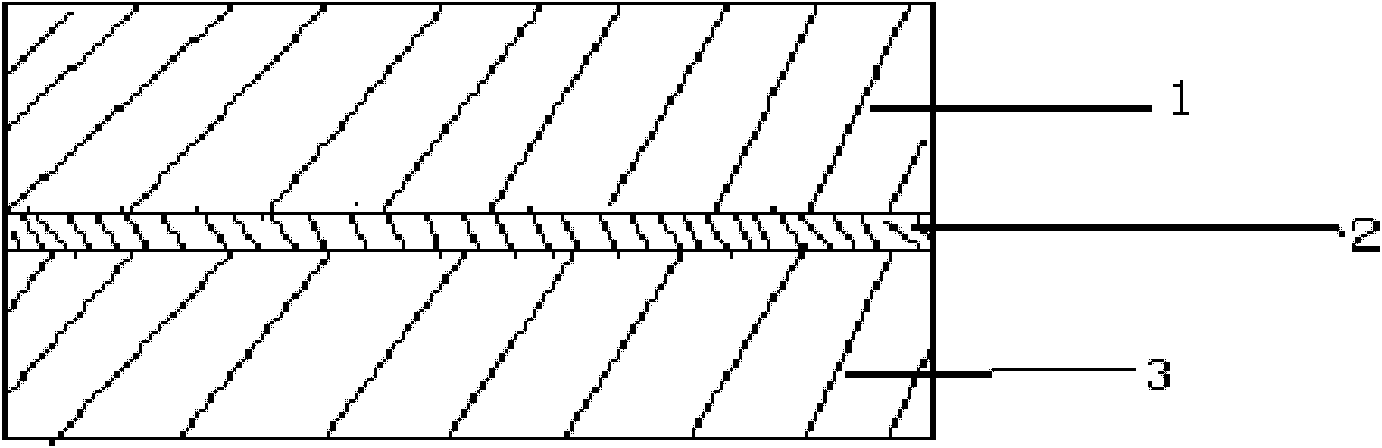

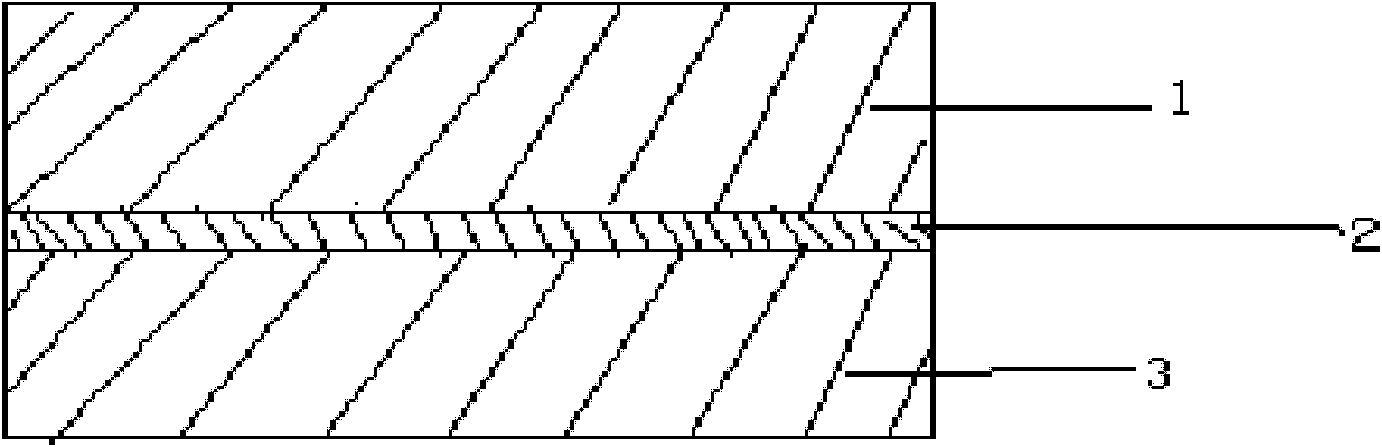

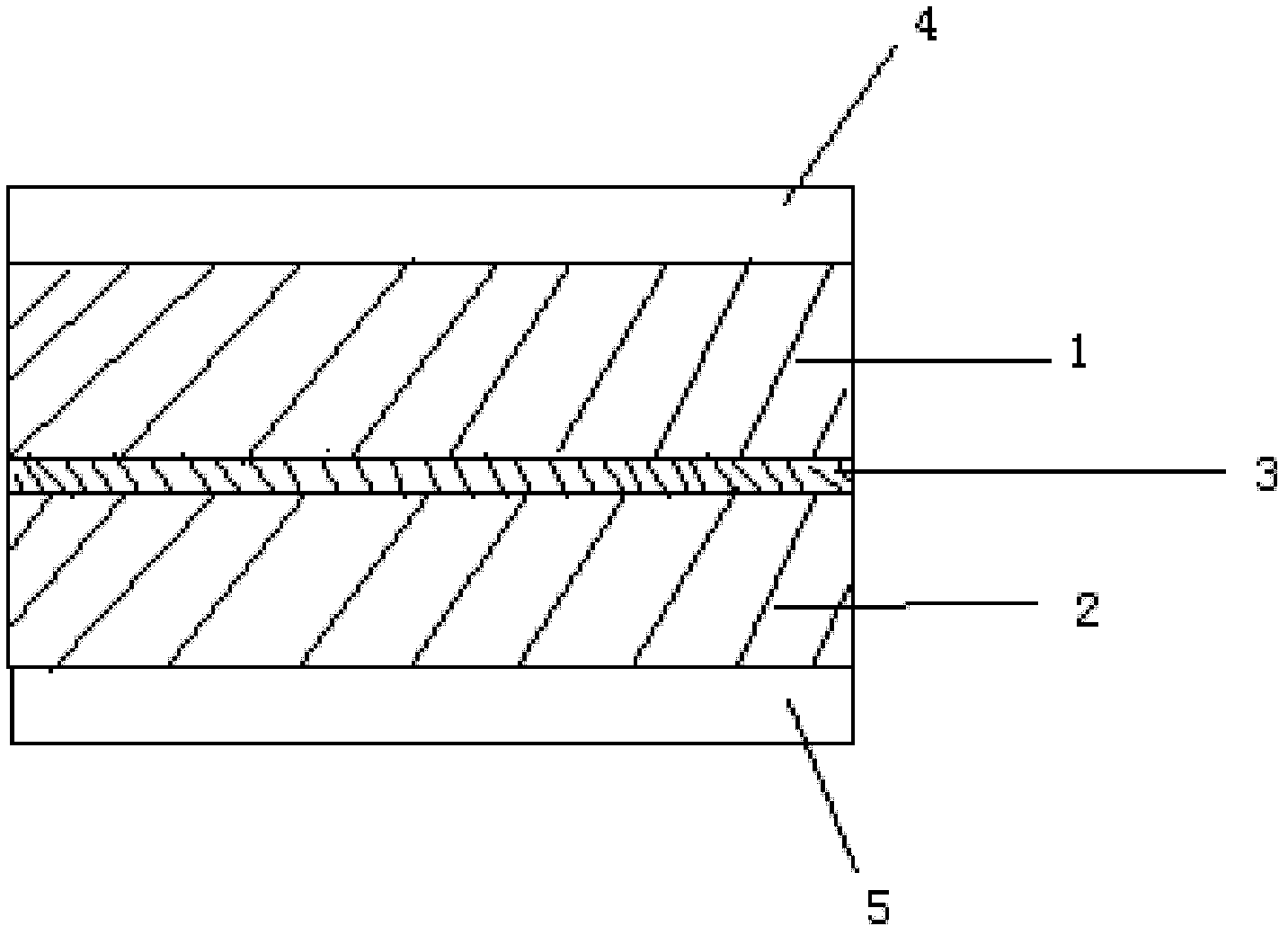

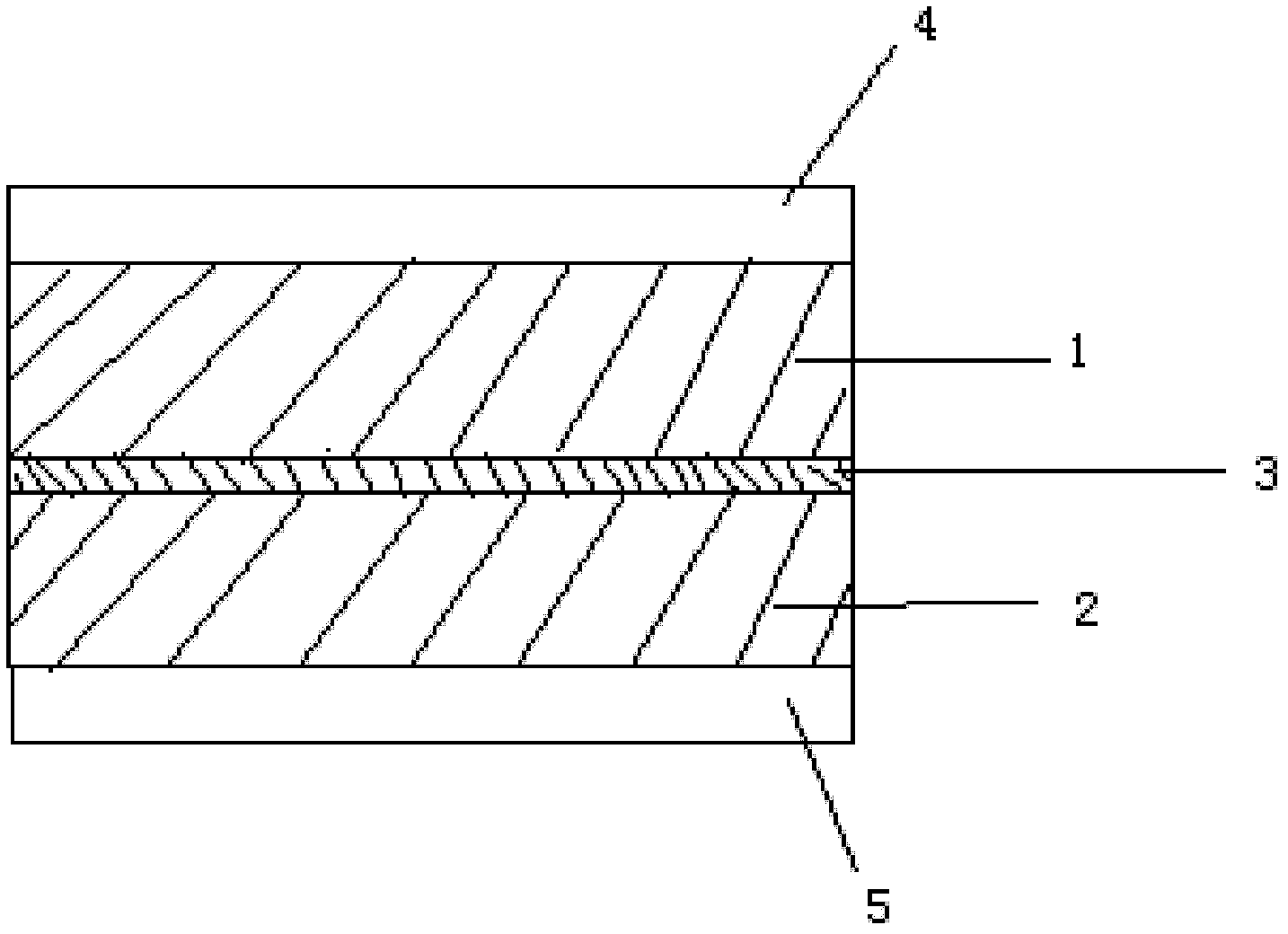

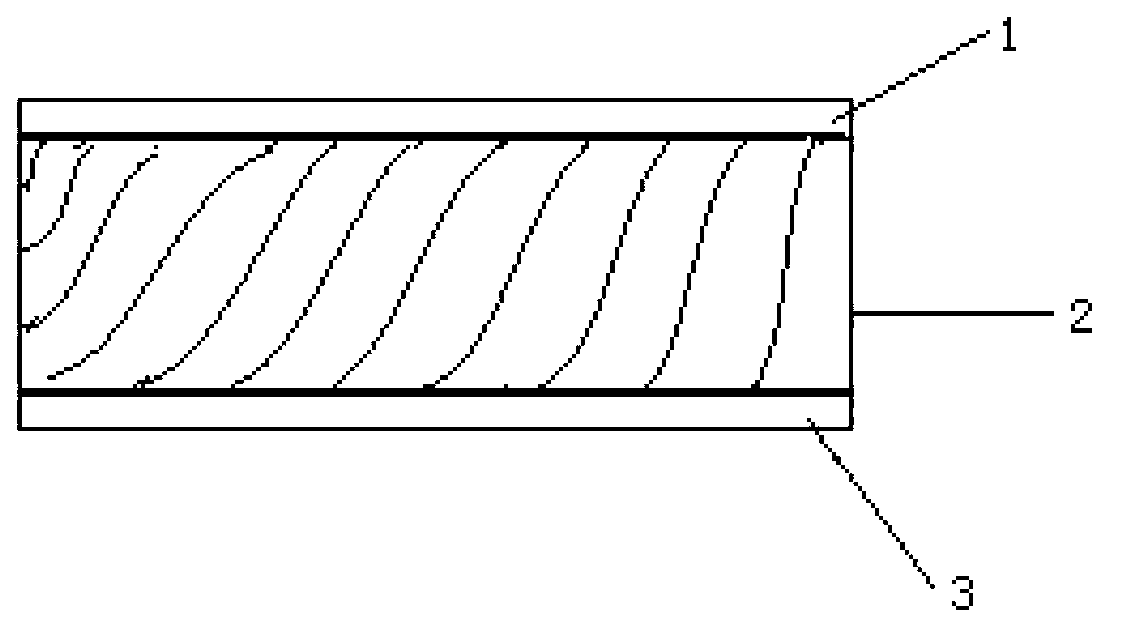

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Healthcare environment-friendly mattress and preparation method thereof

ActiveCN102517796AGood moisture absorption and air permeabilityLight in massNon-woven fabricsCooking & bakingCarding

The invention discloses a healthcare environment-friendly mattress, which comprises the following ingredients of: 5%-50% of low-melting-point fiber and 5%-65% of bastose. The invention further discloses a preparation method of the healthcare environment-friendly mattress, and the preparation method comprises the following steps of: weighing the ingredients according to the required proportion; carrying out loosening and mixing; carrying out pre-laying; carding; carrying out air laying; entering a baking oven; carrying out cold rolling; cooling; and cutting, checking and packaging, wherein thespeed of the processes of pre-laying, carding and air laying is 0-20 m / min, the temperature of the baking oven is 180-230 DEG C, the temperature of cold rolling is 5-20 DEG C, and the cooling temperature is 0-25 DEG C. With the adoption of the healthcare environment-friendly mattress and the preparation method of the healthcare environment-friendly mattress, disclosed by the invention, the problem that the traditional mattress is easily mildewed due to wetting, deteriorated due to worms and easily delaminated is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

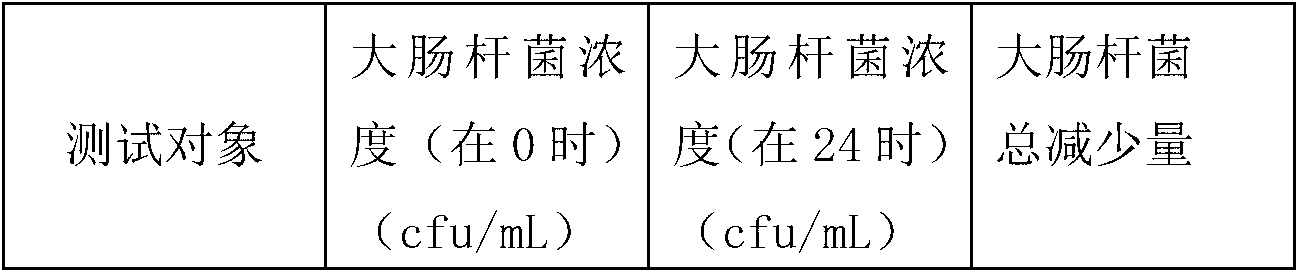

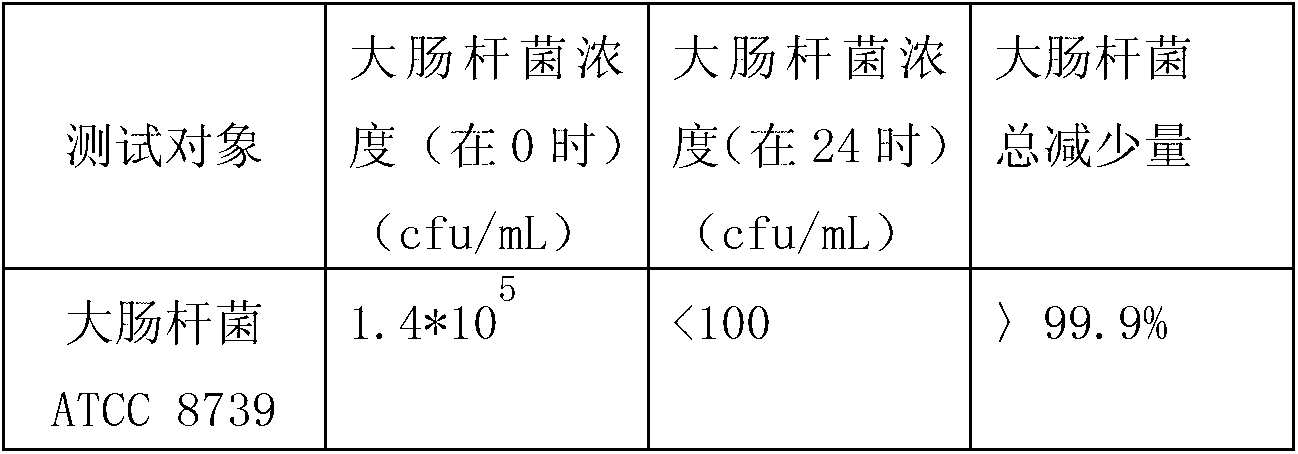

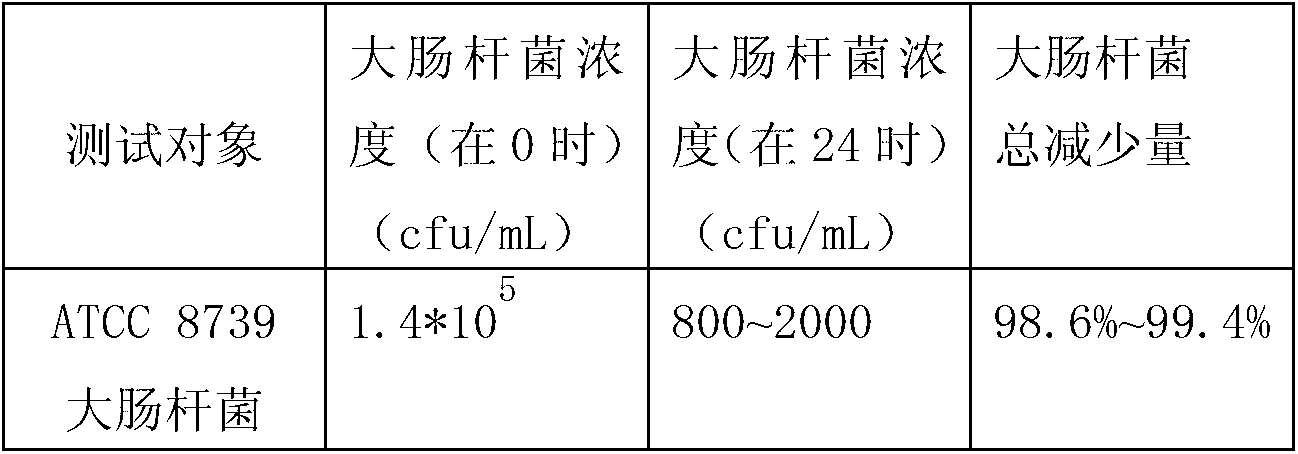

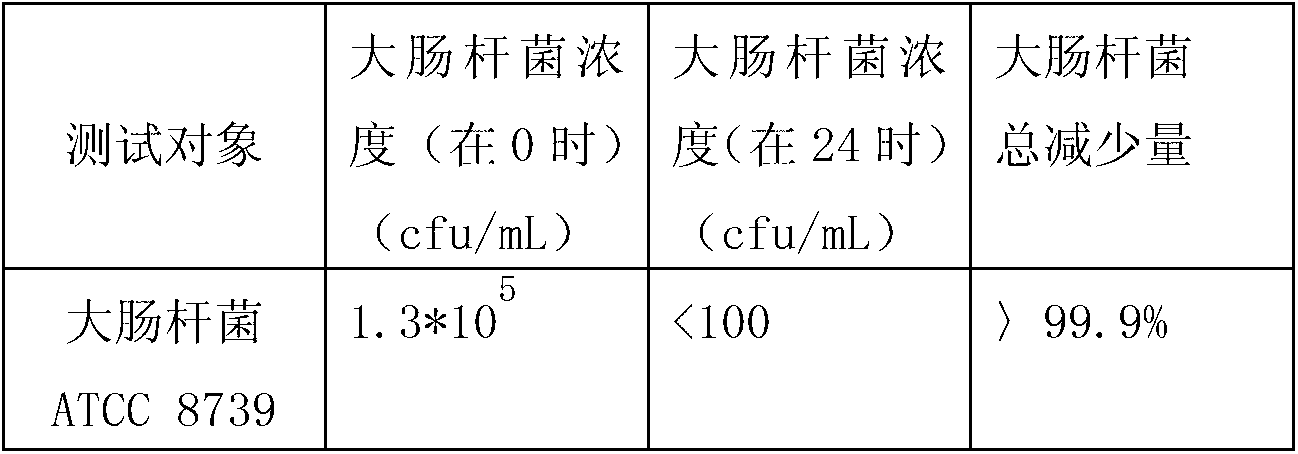

Antibacterial and odor removing fiber bed core and preparation method thereof

InactiveCN103054388AImprove bulkIncrease elasticityStuffed mattressesSpring mattressesFiberPolyester

The invention discloses an antibacterial and odor removing fiber bed core. The fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer comprises a non-woven fabric prepared from the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of polyester fibers; and the middle layer comprises the following components in percentage by weight: 60-85% of raw bamboo fibers and 15-40% of low melting point fibers. The invention further discloses a preparation method of the fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer. The fiber bed core disclosed by the invention has the advantages as follows: antibacterial and odor removing properties, elasticity and bulkiness, healthcare property, ultraviolet resistance, moisture absorbing and removing properties and environment friendliness of the fiber bed core are greatly improved when being compared with those of a traditional mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Compound health protection bed core and preparation method thereof

InactiveCN103054386ANot easy to layerNot easy to be environmentally friendlyUpholstery manufactureStuffed mattressesSurface layerNatural fiber

The invention discloses a compound health protection bed core. The bed core comprises at least one intermediate layer and a surface layer arranged on the upper surface or the lower surface of the intermediate layer, wherein the surface layer is a non-woven layer comprising the following components in percentage by weight: 15-40% of low-melting point fiber and 60-85% of bamboo hemp fiber; the bamboo hemp fiber consists of bamboo fiber and fibrilia; the intermediate layer comprises the following components in percentage by weight: 60-85% of compound natural fiber and 15-40% of low-melting point fiber; the compound natural fiber consists of coconut fiber, bamboo fiber and fibrilia; and the content ratio of the coconut fiber to the bamboo fiber to the fibrilia is 1: 1: (1-3): 2: 1. The invention further comprises a preparation method for the compound health protection bed core; the method comprises the following steps of: respectively preparing various layers which comprise the upper surface layer, the lower surface layer and the intermediate layer, laying the layers sequentially, and preparing the bed core through procedures of oven, cold rolling, cooling, cutting, examining and packaging. The compound health protection bed core and the preparation method thereof solve the technical problems, such as high possibility of layering and rupture, weak elasticity, weak air permeability, mustiness and the like in the existing mattresses.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

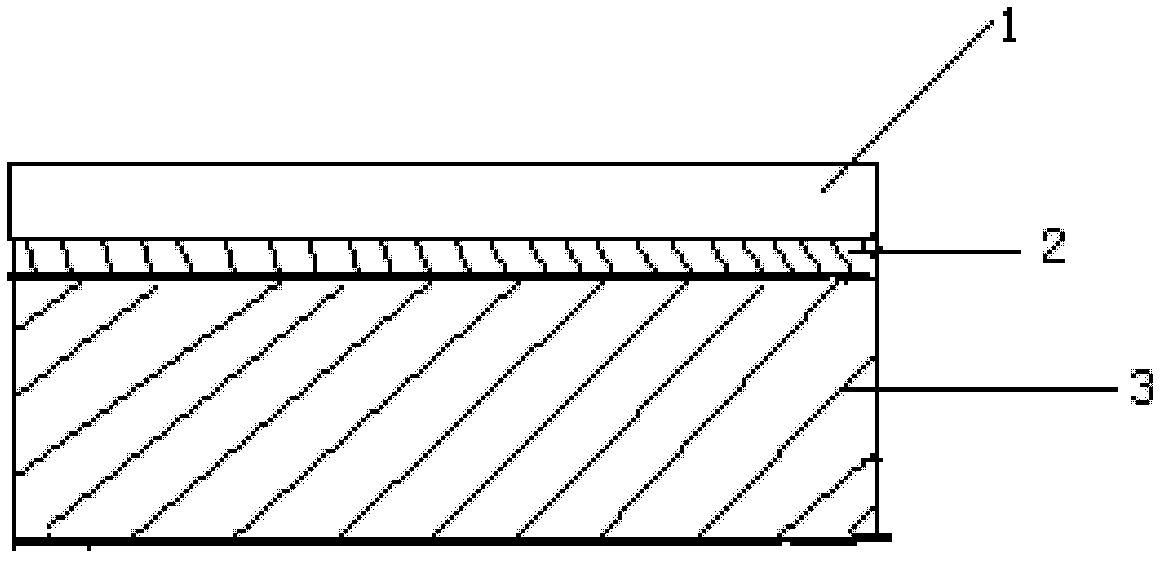

Natural fiber composite plate and manufacturing method thereof

InactiveCN102514255AGood moisture absorption and air permeabilityLight in massLaminationLamination apparatusMetallurgyNatural fiber

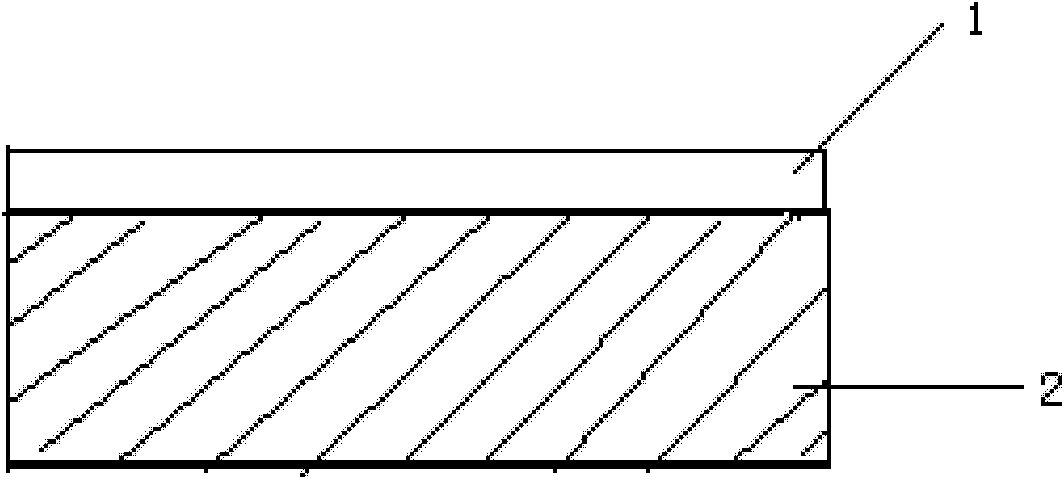

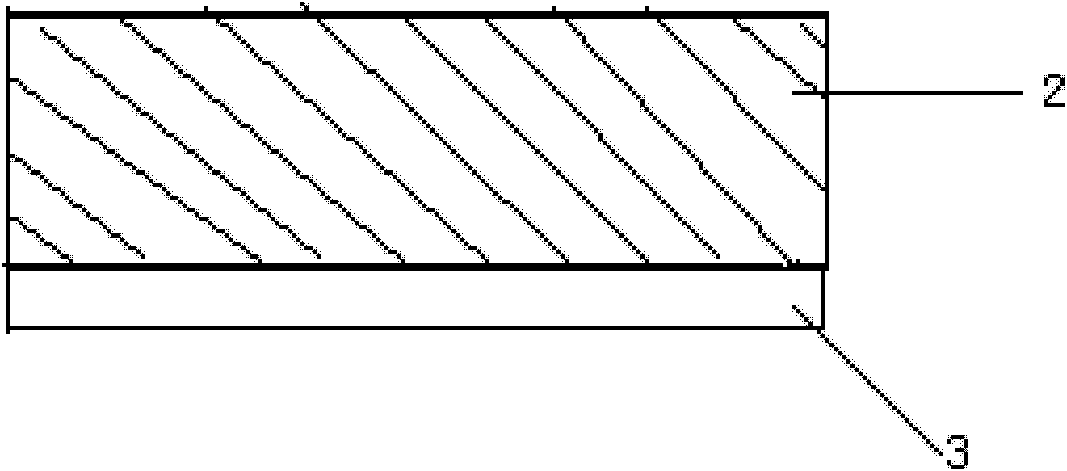

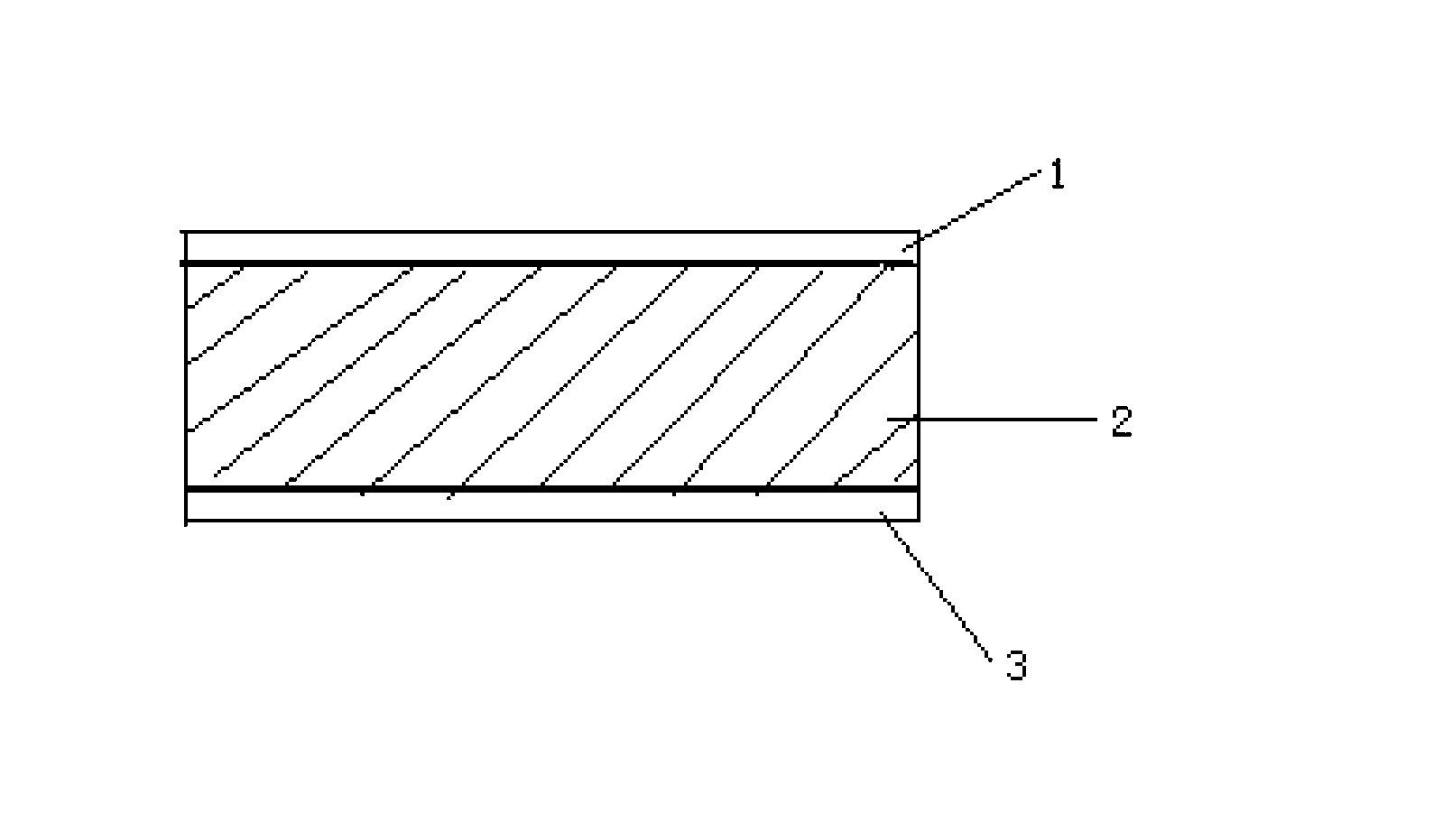

The invention discloses a natural fiber composite plate, which comprises an upper layer, a lower layer and a bonding layer for bonding the upper layer and the lower layer, wherein the upper layer and the lower layer are nonwoven layers comprising the following components: 5 to 50 percent of low melting point fibers and 5 to 65 percent of jute fibers; and the bonding layer is a nonwoven layer comprising 50 to 100 percent of low melting point fibers. The invention also discloses a method for manufacturing the natural fiber composite plate, which comprises the following steps of: respectively preparing various layers, namely the upper layer, the lower layer and the bonding layer; and sequentially spreading the layers, drying in an oven, performing cold rolling, cooling, cutting, checking and packaging to obtain the natural fiber composite plate. By the natural fiber composite plate and the method for manufacturing the natural fiber composite plate, the problem that the conventional mattress is easily moulded with damp, goes bad due to moths and is easily layered is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Composite environmental-friendly cushion and preparation method thereof

InactiveCN102514258AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite environmental-friendly cushion which comprises a middle layer and upper and lower surface layers. The middle layer comprises a first middle layer, a second middle layer and a bonding layer. The upper and lower surface layers are non-woven layers comprising 5 percent to 50 percent of low melting point fibers. The first and second middle layers are non-woven layers which respectively comprise the following components: bastose and 5 percent to 50 percent of low melting point fibers. The bonding layer mainly consists of the low melting point fibers. In the whole composite environmental-friendly cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the composite environmental-friendly cushion, which comprises the following steps of: respectively preparing the middle layer, the upper and lower surface layer and the bonding layer; then sequentially paving the layers; and preparing the composite environmental-friendly cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the composite environmental-friendly cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

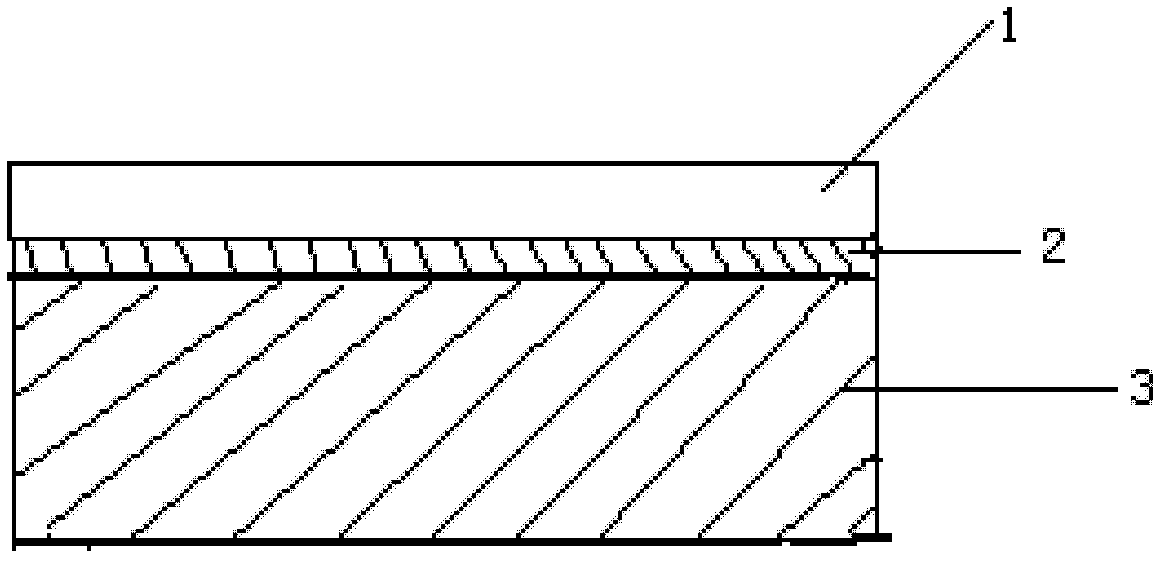

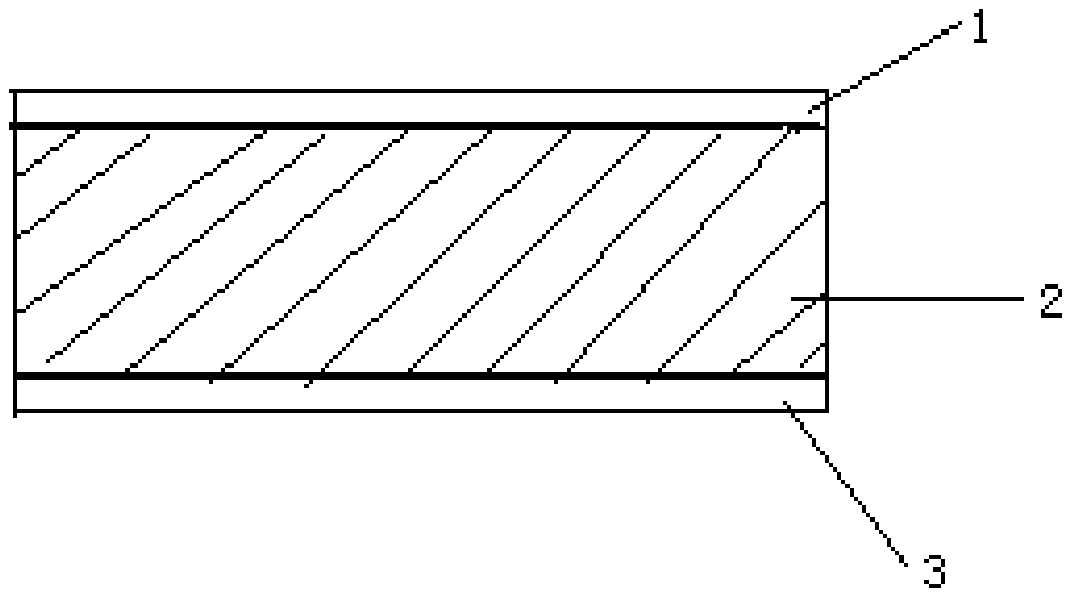

Natural fiber health-care board and preparation method thereof

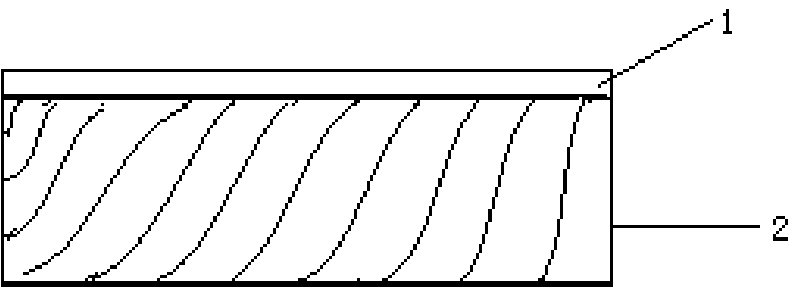

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

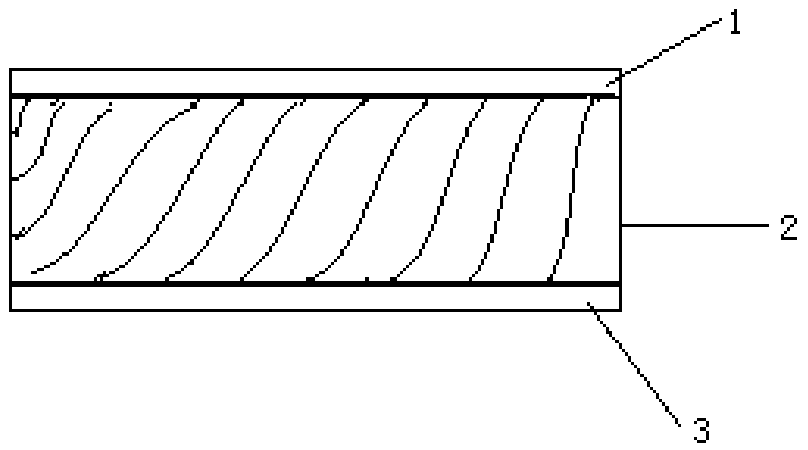

Fiber bed core with good elasticity and preparation method thereof

InactiveCN103054392AIncrease elastic pharyngeal refoldingImprove bulkStuffed mattressesSpring mattressesPolyesterSurface layer

The invention discloses a fiber bed core with good elasticity which comprises at least one intermediate layer and surface layers arranged on the upper surface or the lower surface of the intermediate layer; the surface layers comprise the following components in percentage by weight: 15-40 percent of low-melting point fiber and 60-85 percent of polyester fiber; the intermediate layer comprises the following components in percentage by weight: 60-85 percent of brown hemp fiber and 15-40 percent of low-melting point fiber, wherein the brown hemp fiber consists of coconut fiber and fibrilia in ratio of (1-4):1. The invention also discloses a preparation method of the fiber bed core, which comprises the following steps of: respectively preparing all the layers, i.e. the upper surface layer, the lower surface layer and the intermediate layer, then paving all the layers in sequence and preparing the fiber bed core through the baking, cold-milling, cooling, cutting, inspecting and packaging processes. The fiber bed core and the preparation method thereof have the benefits that the technical problems of easiness in layered fracture, insufficient elasticity, bad air permeability, mustiness and insects existing in the existing bed mattress are solved; and due to the content ratio of the coconut fiber to the brown hemp fiber, the fiber bed core has better elasticity and certain hardness; and fiber bed core is particularly suitable for middle-aged and elderly people.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Crib mattress and manufacturing method thereof

InactiveCN103054401AImprove bulkIncrease elasticityStuffed mattressesSpring mattressesFiberPolyester

The inventional discloses a crib mattress comprising at least one intermediate layer, upper surface layers and lower surface layers, wherein the upper surface layers and the lower surface layers are arranged on the upper surfaces or the lower surfaces of the intermediate layers. Each surface layer is a non-woven layer comprising, by weight, 15-40% of low-fusion-point fibers and 60-85% of polyester fibers. Each intermediate layer comprises, by weight, 60-75% of jute fibers and 25-40% of low-fusion-point fibers. The invention further discloses a manufacturing method of the crib mattress. The manufacturing method includes steps of manufacturing the upper surface layers, the lower surfaces and the intermediate layers and sequentially performing drying in a drying oven, cold rolling, cooling, cutting, checking and packaging. The crib mattress and the manufacturing method thereof solve the technical problems that an existing mattress is easy to mildew and have worms, prone to layering and breaking, poor in elasticity and breathability and not easy to carry, and the like. As the surface layers made of polyester fibers is high in resilience and the intermediate layers made of jute fibers are fine and soft, the crib mattress is quite applicable to infants.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Antibacterial and sweat-absorbent natural fiber bed core and preparation method thereof

InactiveCN103054391ASoft touchImprove comfortStuffed mattressesSpring mattressesSurface layerNatural fiber

The invention discloses an antibacterial and sweat-absorbent fiber bed core. The antibacterial and sweat-absorbent natural fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer comprises the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of raw bamboo fibers; the middle layer comprises the following components in percentage by weight: 60-85% of bamboo vamp fibers and 15-40% of low melting point fibers; the bamboo vamp fibers comprise raw bamboo fibers and hemp fibers; and the content ratio of the raw bamboo fibers to the hemp fibers is 1-4:1. The invention further discloses a preparation method of the natural fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer. According to the invention, through adoption of the natural fiber bed core and the preparation method thereof, the technical problems of poor mite-resistant and antibacterial properties, easiness for layering and cracking, insufficient elasticity, poor ventilating property, mildews, insects and the like in the traditional mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

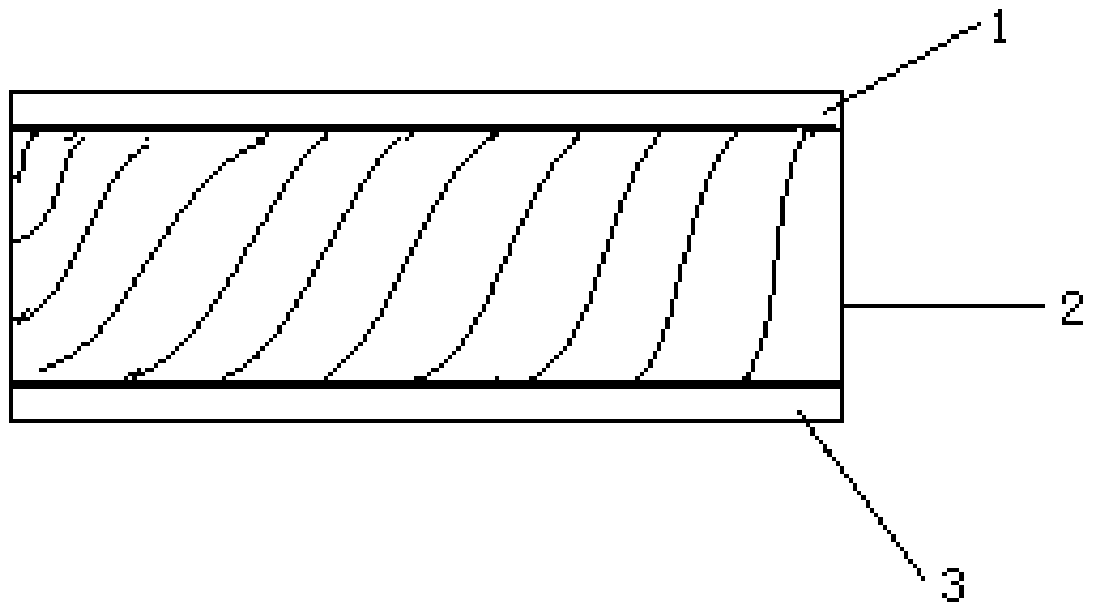

Composite natural fibre bed core and preparation method thereof

InactiveCN103271585ANot easy to layerLow densityUpholstery manufactureStuffed mattressesNatural fiberSurface layer

The invention discloses a composite natural fibre bed core, which comprises at least one interface layer and surface layers equipped on the upper surface or lower surface of the interface layer, and the surface layer is a nonwoven layer which is composed of the following components by weight percent: low melting point fiber 15-40% and fibriia 60-85%, and the interface layer is composed of the following components by weight percent composite natural fibre 60-85% and low melting point fiber 15-40%, and the composite natural fibre is composed of coconut fiber, bamboo fibril and fibriia, and the ratio between coconut fiber: bamboo fibril: fibriia is 1:1:1-3:2:1. The invention also discloses a preparation method of natural fibre bed core, which comprises the following steps: respectively preparing each layer containing the up and down surface layer and the interface layer, and then paving in sequence, drying by baking oven, cold rolling, cooling, cutting, examining and packing. The natural fibre bed core and the preparation method solve the technology problems such as easy layering and fracture, less elasticity, bad permeability, mildew and insect generation, etc. in the present mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Compound natural fiber health protection bed core and preparation method thereof

InactiveCN103054393AGood moisture absorption and air permeabilityLight in massUpholstery manufactureStuffed mattressesHemp fiberHealth protection

The invention discloses a compound natural fiber health protection bed core. The bed core comprises at least one intermediate layer and a surface layer arranged on the upper surface or the lower surface of the intermediate layer, wherein the surface layer is a non-woven layer comprising the following components in percentage by weight: 15-40% of low-melting point fiber and 60-85% of bamboo fiber; the intermediate layer comprises the following components in percentage by weight: 60-85% of brown hemp fiber and 15-40% of low-melting point fiber; the brown hemp fiber consists of coconut fiber and fibrilia; and the weight ratio of the coconut fiber to the hemp fiber is (1-4): 1. The invention further comprises a preparation method for the compound natural fiber health protection bed core; the method comprises the following steps of: respectively preparing various layers which comprise the upper surface layer, the lower surface layer and the intermediate layer, laying the layers sequentially, and preparing the bed core through procedures of oven, cold rolling, cooling, cutting, examining and packaging. The natural fiber bed core and the preparation method thereof solve the technical problems, such as high possibility of layering and rupture, weak elasticity, weak air permeability, mustiness and the like in the existing mattresses.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Fiber bed core and preparation method thereof

InactiveCN103054384AIn line with natureIn line with the green conceptStuffed mattressesSpring mattressesSurface layerNanotechnology

The invention discloses a fiber bed core. The fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is a non-woven layer which comprises the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of raw bamboo fibers; and the middle layer comprises the following components in percentage by weight: 60-75% of hemp fibers and 25-40% of low melting point fibers. The invention further discloses a preparation method of the fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the fiber bed core. Through adoptions of the fiber bed core and the preparation method thereof disclosed by the invention, technical problems of easiness for layering and cracking, insufficient elasticity, poor ventilating property, mildews, insects, uneasiness for conveying and the like in the current mattres are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Natural fiber bed core and preparation method thereof

InactiveCN103054387AGood moisture absorption and air permeabilityLight in massStuffed mattressesSpring mattressesSurface layerPalm fiber

The invention discloses a natural fiber bed core. The natural fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is a non-woven layer prepared by the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of hemp fibers; the middle layer comprises the following components in percentage by weight: 60-85% of bamboo palm fibers and 15-40% of low melting point fibers; the bamboo palm fibers comprise coconut palm fibers and raw bamboo fibers; and the content ratio of the coconut palm fibers and the raw bamboo fibers is 1-4:1. The invention further discloses a preparation method of the natural fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the natural fiber bed core. According to the invention, through adoptions of the natural fiber bed core and the preparation method thereof, technical problems of easiness for layering and cracking, insufficient elasticity, poor ventilating property, mildews, insects and the like in the current mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

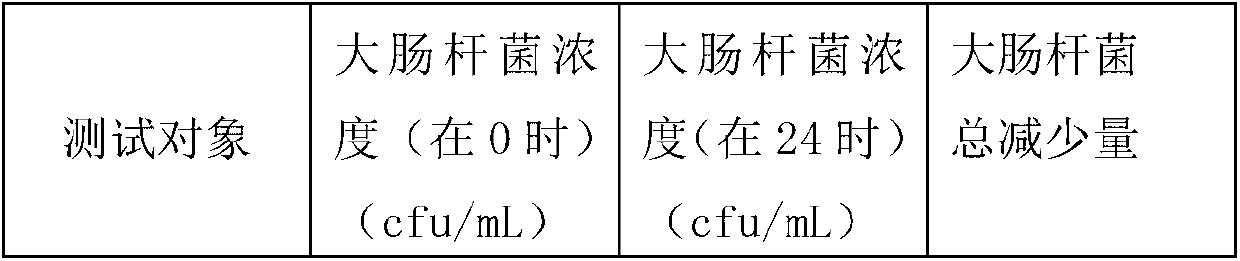

Antibacterial and mite-suppression bed core for babies and method for manufacturing antibacterial and mite-suppression bed core

InactiveCN103054400ANot easy to layerNot easy to be environmentally friendlyStuffed mattressesSpring mattressesSurface layerUltraviolet

The invention discloses an antibacterial and mite-suppression bed core for babies. The antibacterial and mite-suppression bed core comprises at least one middle layer and surface layers, the surface layers are arranged on upper surfaces or lower surfaces of the middle layers, each surface layer is a non-woven layer comprising, by weight, from 15% to 40% of fibers with low melting points and from 60% to 85% of hemp fibers, and each middle layer comprises, by weight, from 60% to 85% of natural bamboo fibers and from 15% to 40% of fibers with low melting points. The invention further discloses a method for manufacturing the antibacterial and mite-suppression bed core for the babies. The method includes steps of respectively manufacturing the various layers including the upper and lower surface layers and the middle layers; sequentially laying the upper and lower surface layers and the middle layers; and performing oven drying, cold rolling, cooling, cutting and inspection and packing procedures to manufacture the antibacterial and mite-suppression bed core. The antibacterial performance, the healthcare performance, ultraviolet resistance, moisture absorption and removal properties and an environmental protection property of the antibacterial and mite-suppression bed core for the babies are greatly improved as compared with an existing mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Composite natural fibre bed core and preparation method thereof

InactiveCN103271586ANot easy to layerNot easy to be environmentally friendlyUpholstery manufactureStuffed mattressesSurface layerFibril

The invention discloses a composite natural fibre bed core, which comprises at least one interface layer and surface layers equipped on the upper surface or lower surface of the interface layer, and the surface layer is a nonwoven layer which is composed of the following components by weight percent: low melting point fiber 15-40% and fibriia 60-85%, and the interface layer is composed of the following components by weight percent composite natural fibre 60-85% and low melting point fiber 15-40%, and the composite natural fibre is composed of coconut fiber, bamboo fibril and fibriia, and the ratio between coconut fiber: bamboo fibril: fibriia is 1:1:1-3:2:1. The invention also discloses a preparation method of natural fibre bed core, which comprises the following steps: respectively preparing each layer containing the up and down surface layer and the interface layer, and then paving in sequence, drying by baking oven, cold rolling, cooling, cutting, examining and packing. The natural fibre bed core and the preparation method solve the technology problems such as easy layering and fracture, less elasticity, bad permeability, mildew and insect generation, etc. in the present mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Environmental protection board for interior decoration and preparation method thereof

InactiveCN103114696AGood moisture absorption and air permeabilityHigh hardnessLamination ancillary operationsCovering/liningsFiberGram

The invention discloses an environmental protection board for interior decoration and a preparation method thereof. The environmental protection board for the interior decoration comprises a base plate and a polyethylene (PE) film arranged on the surface of the base plate, wherein a non-woven fabric layer is arranged between the base plate and the PE film, the base plate is composed of 50-80% of jute fiber, 20-50% of low melting point fiber and 0-30% of alpinia fiber based on weight percentage. According to the environmental protection board for the interior decoration, the base plate is compositely manufactured by the low melting point fiber and the jute fiber, the PE film further covers the base plate, no other composition is added, thus the fact that no other harmful chemical substance is contained in the environmental protection board for interior decoration is guaranteed, and the environmental protection board for interior decoration has no harm to a human body, meanwhile the jute fiber has good moist absorption performance and breathability, and is antimicrobial and mite proof. The environmental protection board is light and solid, capable of replacing decorative materials such as wall paper and paint, and can be used in places needing to be decorated such as a wall and a roof directly. The gram weight of a prepared product can reach to 100-500g / m2, and the thickness of the prepared product is 0.2-5mm.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

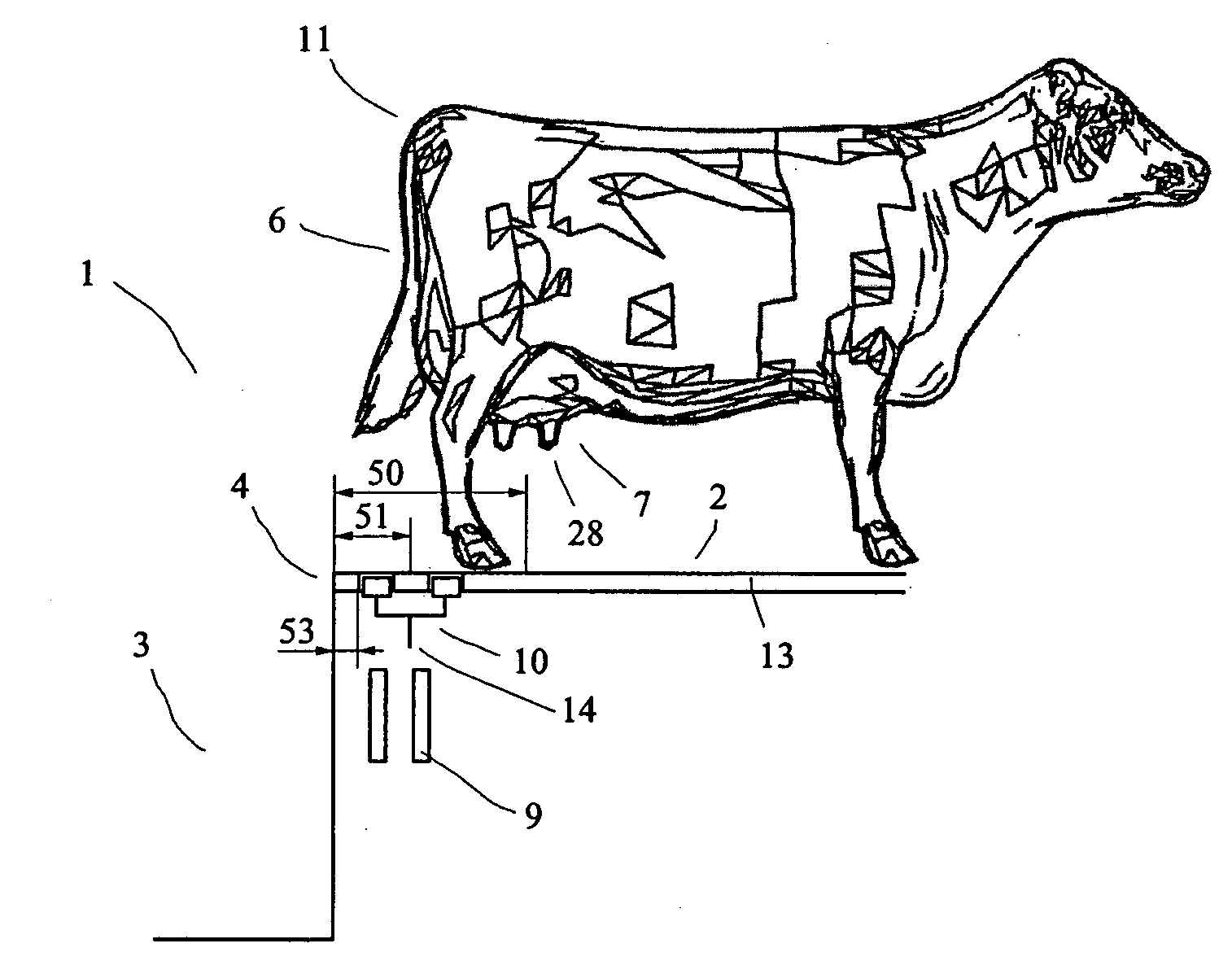

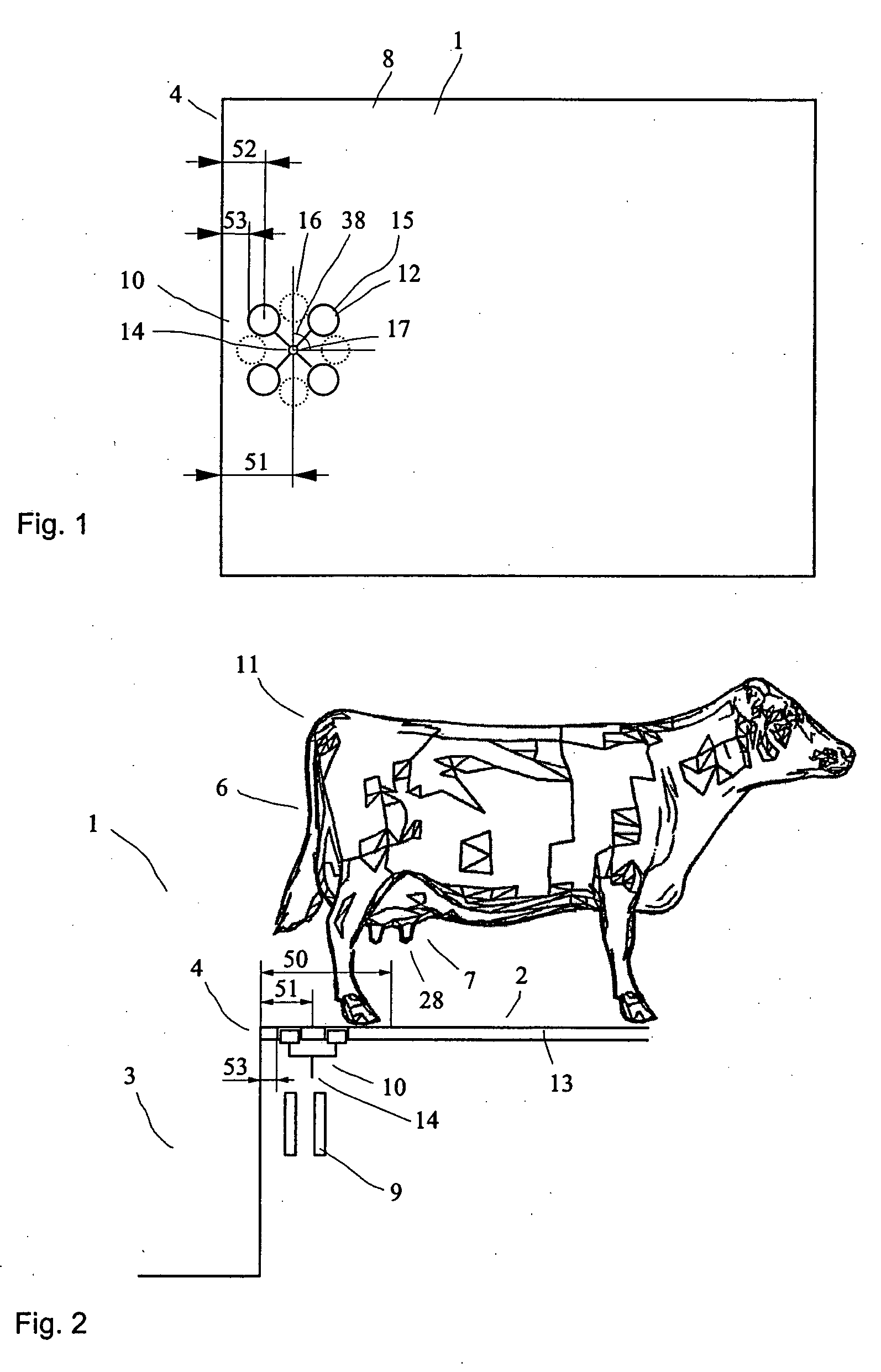

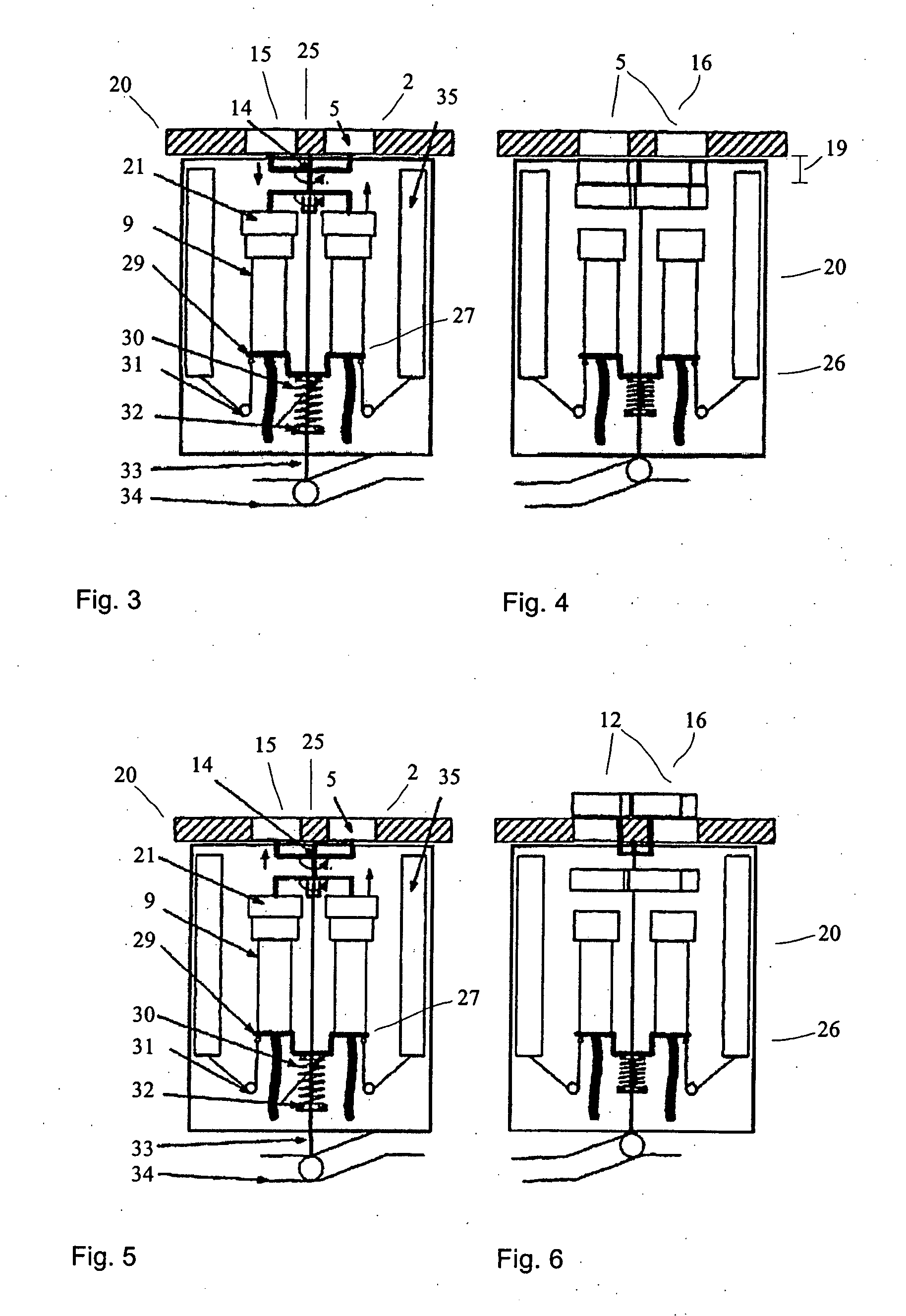

Milking parlor

InactiveUS20080210171A1Improve security levelEliminate riskCathetersAnimal housingRotational axisEngineering

A milking parlor, milking module, and a closing unit comprising at least two closing members to optionally release or close a corresponding number of openings in a milking parlor floor which serves as a standing area. The closing members are disposed to be rotatable about a rotational axis at least between a closed position and an open position, wherein the open position allows at least one animal-related treatment means to be guided through said opening. Said rotational axis is disposed in a central region between the closing members.

Owner:GEA WESTFALIASURGE GMBH

Natural fiber composite health-care cushion and preparation method thereof

ActiveCN102514274AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLayered productsSurface layerNatural fiber

The invention discloses a natural fiber composite health-care cushion which comprises a middle layer. A surface layer is arranged on the upper surface or the lower surface of the middle layer. A block layer is arranged between the middle layer and the surface layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. The block layer is a non-woven layer comprising 5 percent to 100 percent of low melting point fibers. In the natural fiber composite health-care cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber composite health-care cushion, which comprises the following steps of: respectively preparing the middle layer, the upper or lower surface layer and the block layer; then sequentially paving the layers; and preparing the natural fiber composite health-care cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption ofthe natural fiber composite health-care cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer, has poor air permeability and is discomfortable to use due to protruded hard fibers in the middle of the mattress is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Healthcare natural fiber bed core and preparation method thereof

InactiveCN103054394AGood moisture absorption and air permeabilityLight in massStuffed mattressesSpring mattressesSurface layerPalm fiber

The invention discloses a healthcare natural fiber bed core. The healthcare natural fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is the non-woven layer prepared by the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of hemp fibers; the middle layer comprises the following components in percentage by weight: 60-85% of brown hemp fibers and 15-40% of low melting point fibers; the brown hemp fibers comprise coconut palm fibers and hemp fibers; and the content ratio of the coconut palm fibers and the hemp fibers is 1-4:1. The invention further discloses a preparation method of the healthcare natural fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the healthcare natural fiber bed core. According to the invention, through adoptions of the healthcare natural fiber bed core and the preparation method thereof, technical problems of easiness for layering and cracking, insufficient elasticity, poor ventilating property, mildews, insects and the like in the current mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

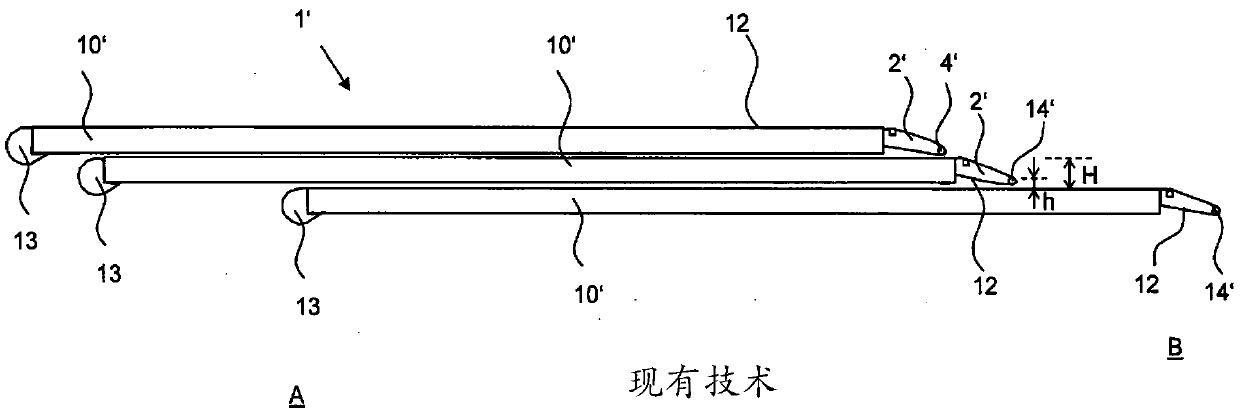

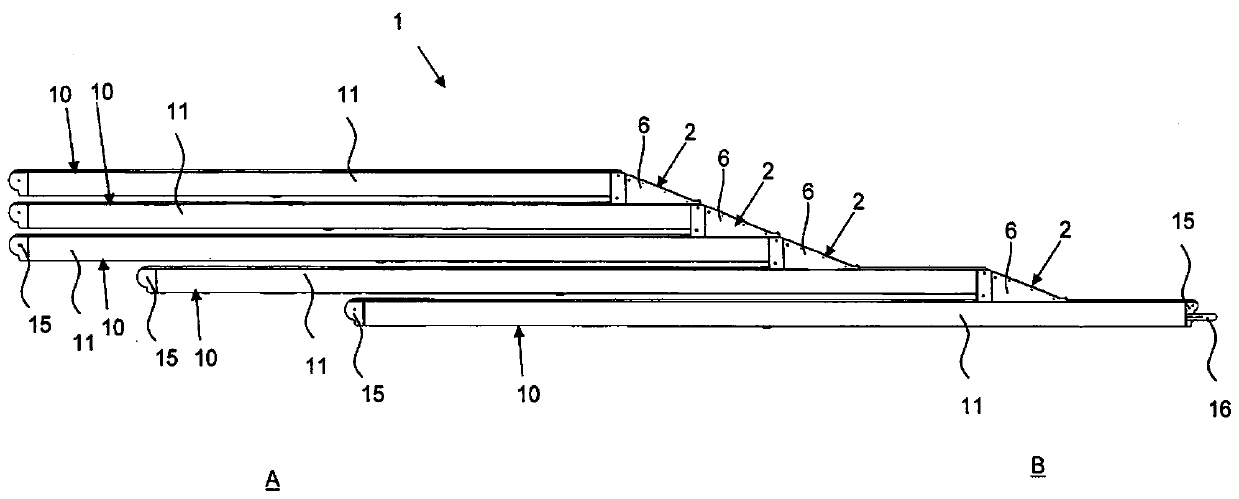

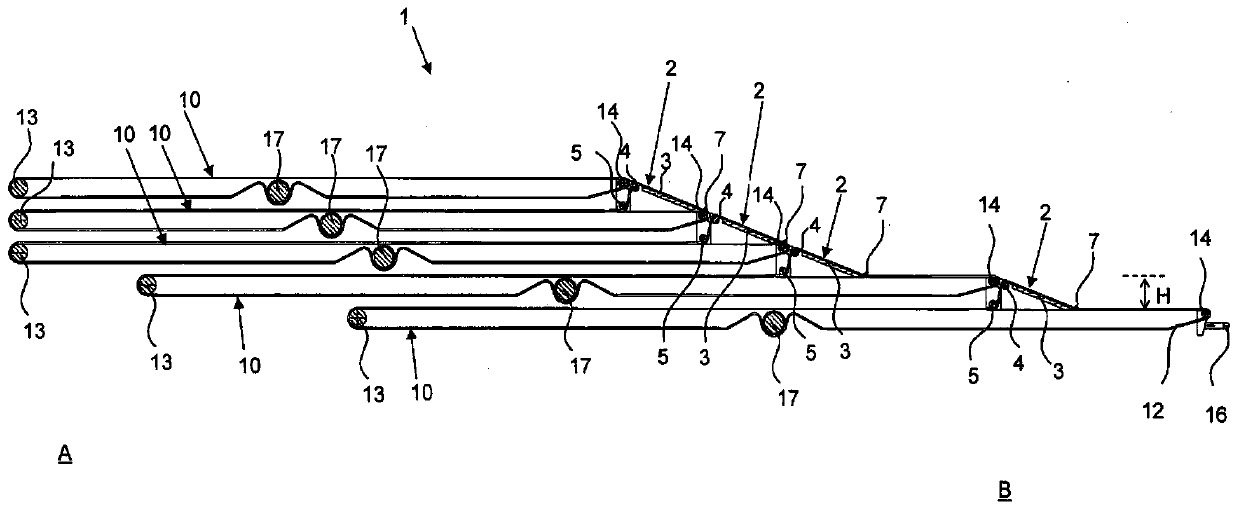

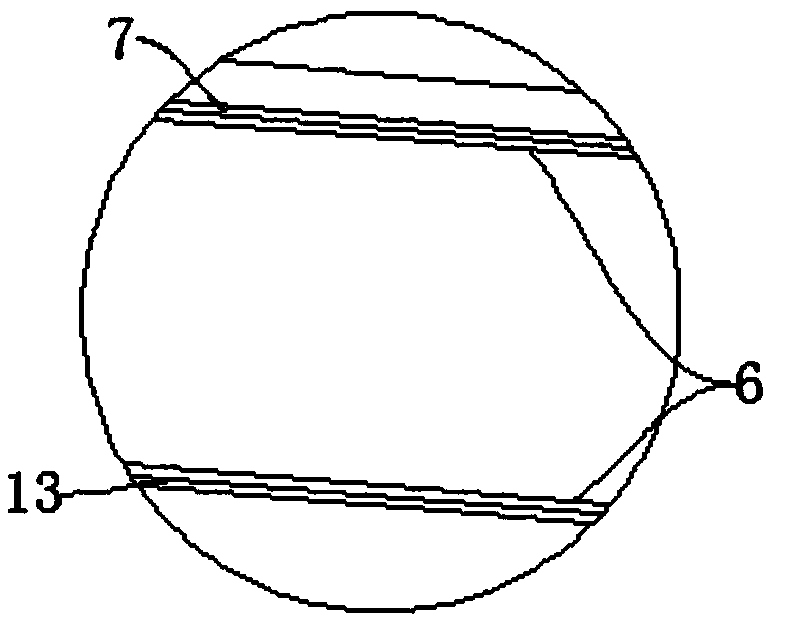

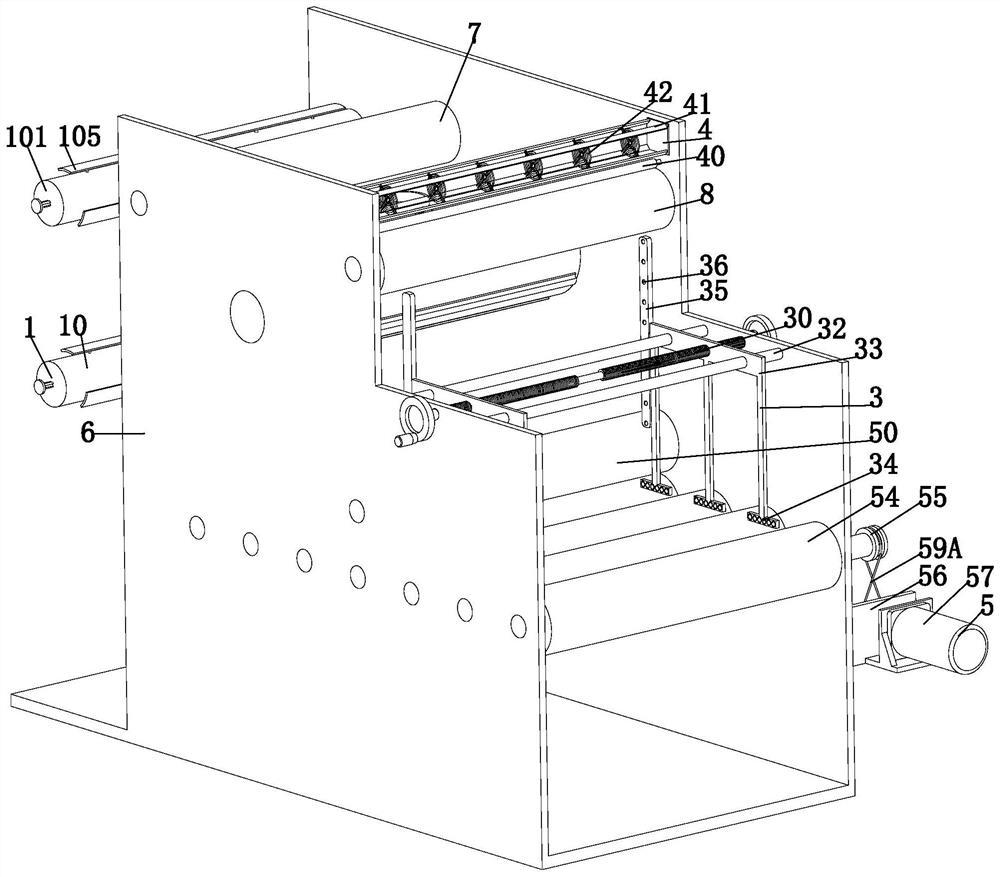

Telescopic conveyor

The present invention provides a telescopic conveyor (1) having at least two conveyor belts (10). Said belts are arranged one above the other and can be moved relative to one another in the longitudinal direction. Each conveyor belt (10) here has a frame (11), a circulatory belt (12) and a first deflecting roller (13) at a first end (A), and a second deflecting roller (14) at a second end (B), ofthe conveyor belt (10), wherein the second end (B) is a transfer end of the conveyor belt (10), and wherein a bridging device (2', 2) is provided between in each case two adjacent conveyor belts (10)located one above the other, and said device bridges, at least to some extent, the difference in height (H) between the two conveyor belts (10) arranged one above the other, it being necessary for said difference in height to be overcome at the transfer end. The bridging device (2) comprises a ramp (3, 3') with a slope (S) and also a first deflecting roller (4), which is arranged at the higher endof the ramp (3, 3'), as well as a first holding-down device (5), which is arranged beneath the first deflecting roller (4), and also a second holding-down device (7) at the foot of the ramp (3, 3').The circulatory belt (12) of the respectively lower conveyor belt (10) is guided, from a conveying plane (E1) beneath the second holding-down device (7), over the ramp (3, 3') with the slope (S) and,from there, is deflected over the first deflecting roller (4) and guided back to the conveying plane (E1) beneath the first holding-down device (5). The slope (S) of the ramp (3, 3') continues in stepless fashion tangentially along the circulatory belt (12) of the conveyor belt (10) located above, said circulatory belt being guided over its second end-side deflecting roller (14).

Owner:加沃斯基股份有限公司

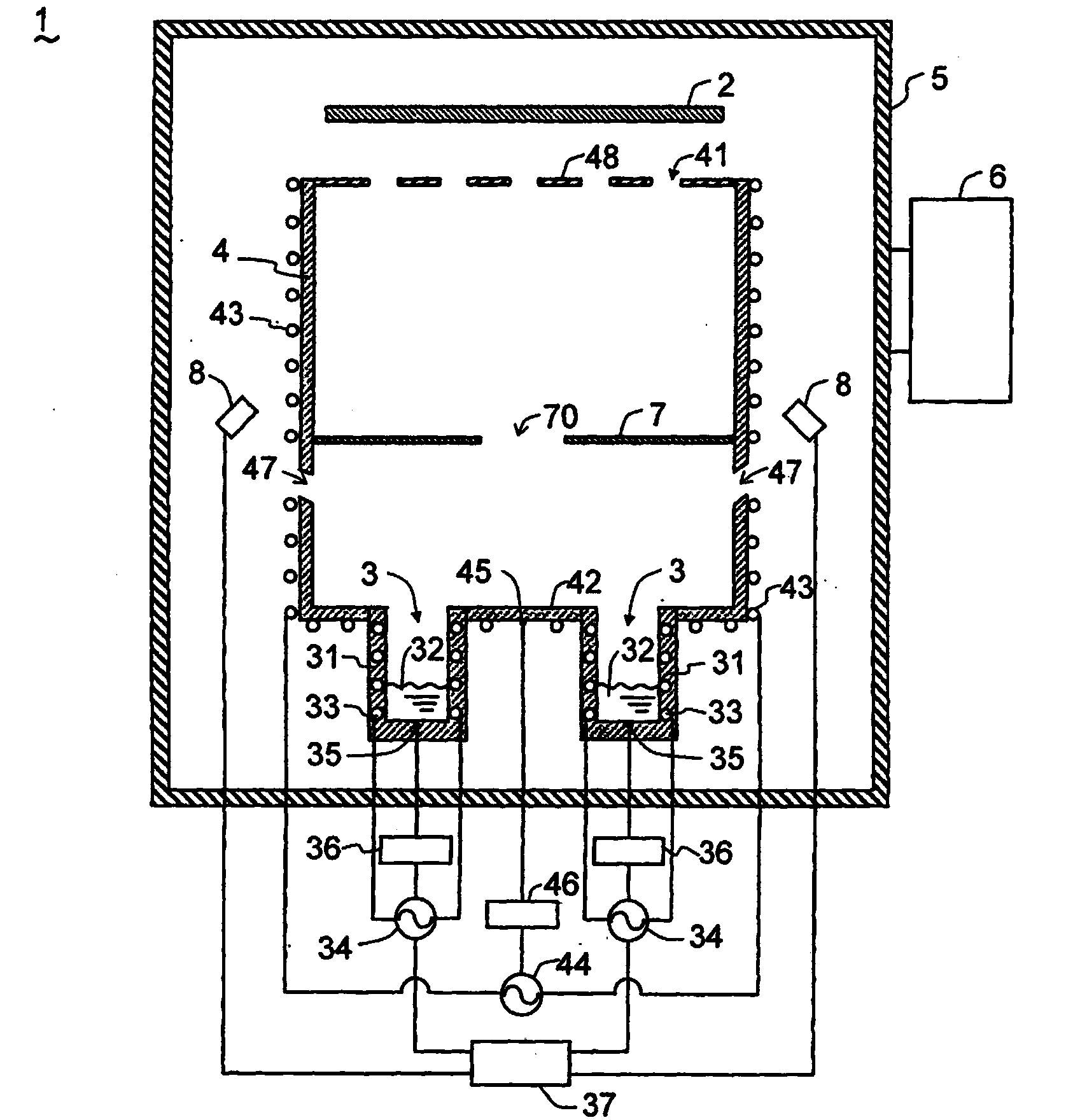

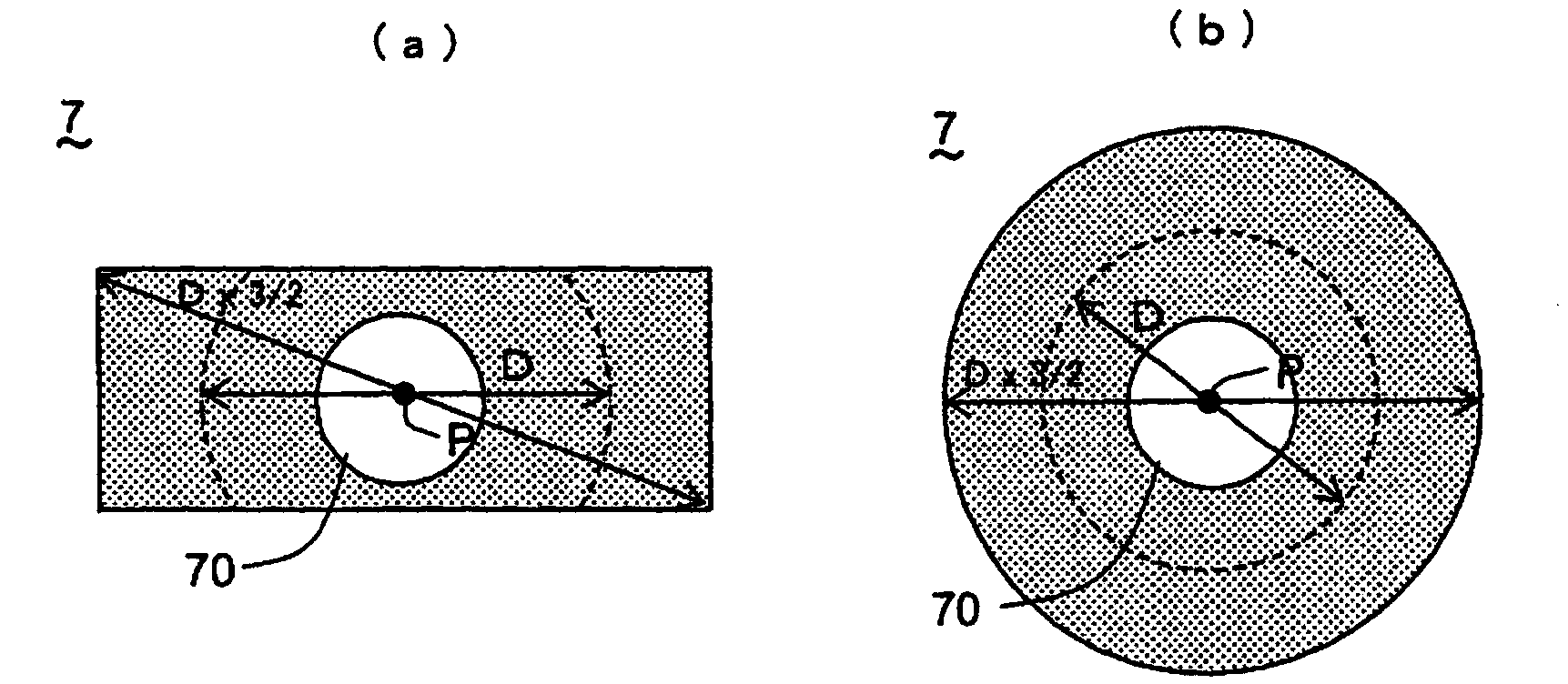

Vacuum deposition device

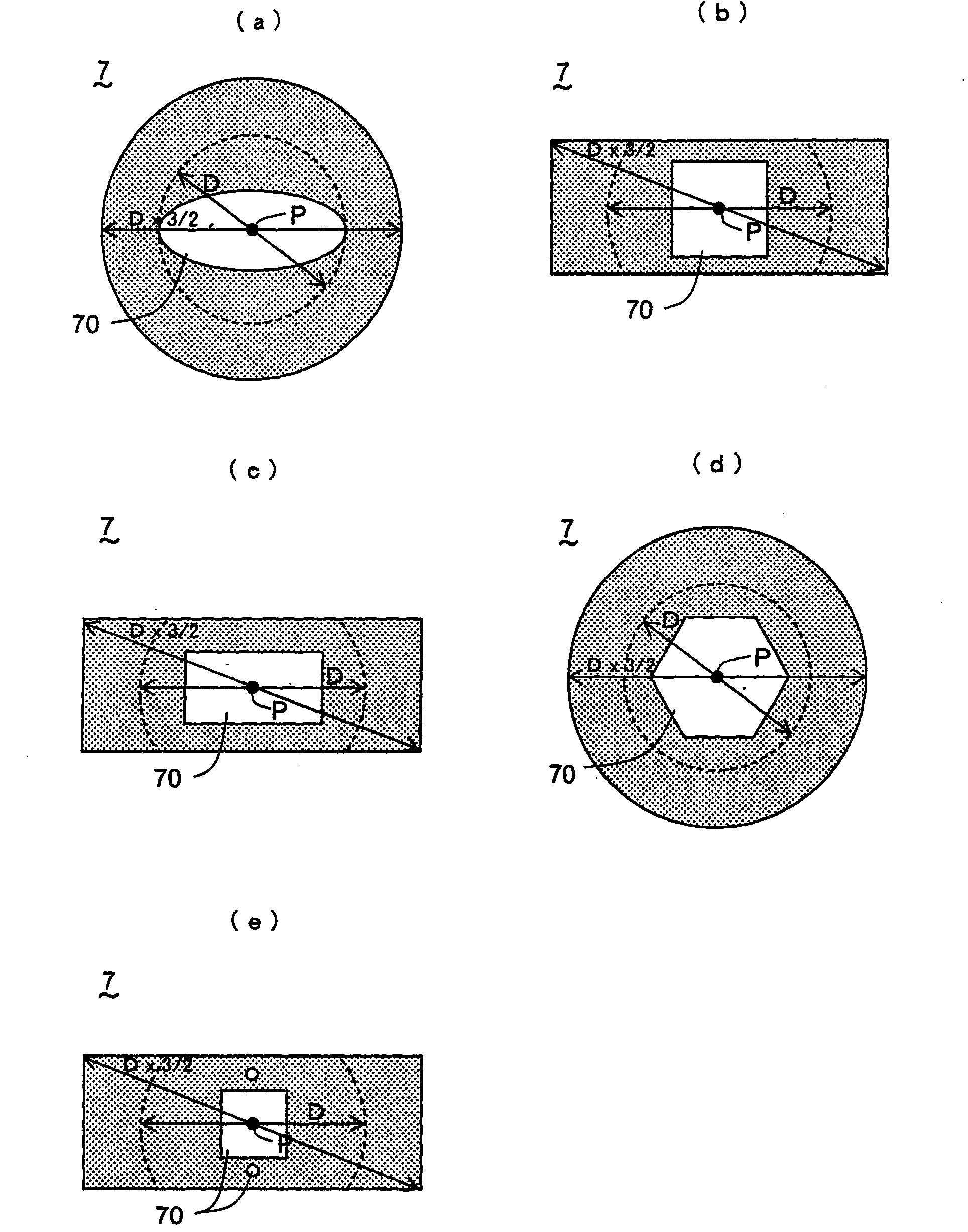

[Problem] To configure a vacuum deposition device so that non-uniformity of a deposited film formed on a body is less likely to occur when multiple evaporation sources are used, and a deposited film with a desired film thickness can be formed. [Solution] The vacuum deposition device (1) is provided with: multiple evaporation sources (3); and a cylindrical body (4) that surrounds the space between the evaporation sources (3) and a body (2) onto which a film is to be deposited, and has an aperture plane (41) on the side facing the body (2) onto which a film is to be deposited. Also, the vacuum deposition device has a partitioning plate (7) that is provided inside the cylindrical body (4). The partitioning plate (7) has aperture sections (70). One or more aperture sections (70) are provided within the range of a circumference having a diameter of D around the center of gravity (P).; The diameter (D) is 2 / 3 of the maximum value of the distance between two points on the outer circumference of the partitioning plate (7). This configuration can achieve a uniform flux distribution for an evaporation material from the aperture sections (70) of the partitioning plate (7) to the body (2) onto which a film is to be deposited. Thus, non-uniformity of the deposited film formed on the body (2) is less likely to occur when multiple evaporation sources (3) are used, and a deposited film with a desired film thickness can be formed.

Owner:PANASONIC CORP

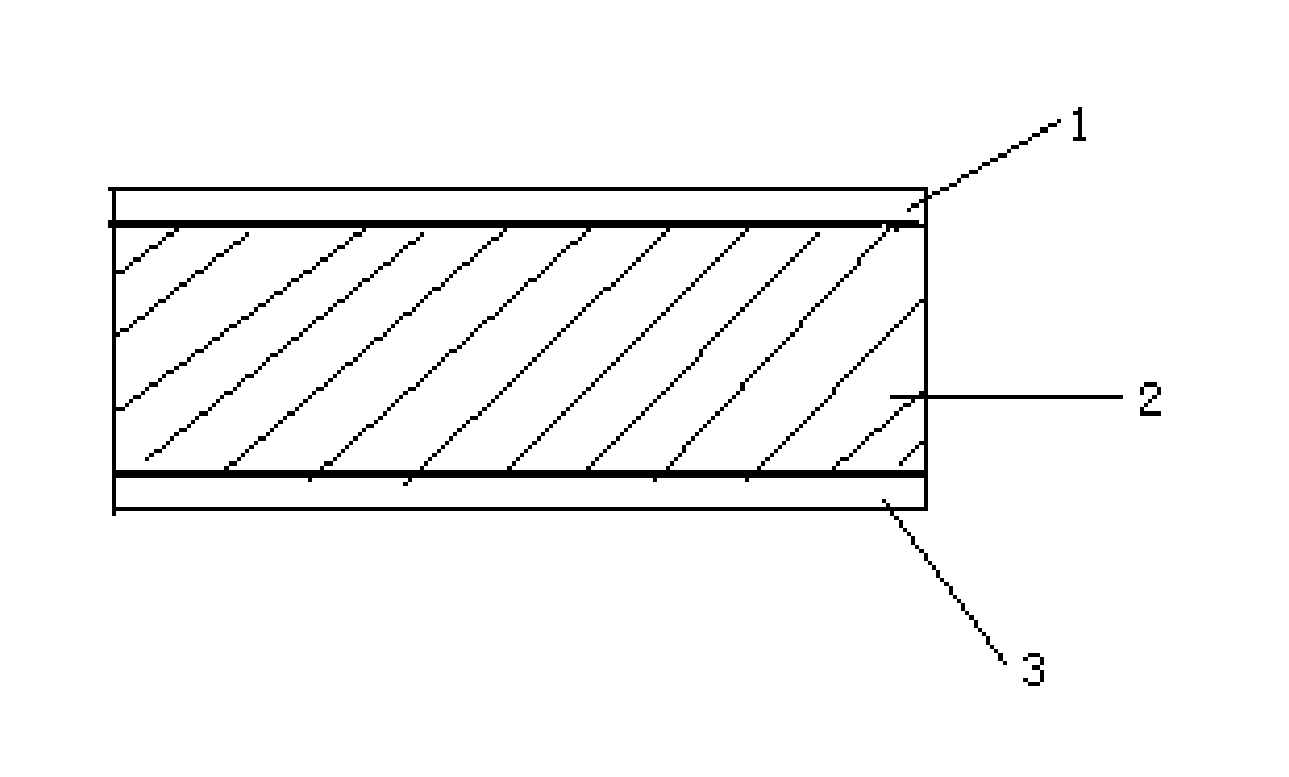

Household-decoration-use environment-friendly multi-layer composite board and preparation method thereof

ActiveCN103104081AGood moisture absorption and air permeabilityGuaranteed hardnessCovering/liningsLayered productsFiberHardness

The invention discloses a household-decoration-use environment-friendly multi-layer composite board and a preparation method of the household-decoration-use environment-friendly multi-layer composite board. The multi-layer composite board is composed of a multi-layer board and a decorative layer in a composite mode. At least two layers of single-layer boards are composited into a whole to form the household-decoration-use environment-friendly multi-layer composite board. Each of the single-layer boards is selected from a component 1 and a component 2, and two adjacent single-layer boards are different in component, wherein the component 1 comprises, by weight, 50-80 % of fibrilia and 20%-50% of low melting point fiber, and the component 2 comprises, by weight, 50-80 % of fibrilia, 20%-50% of low melting point fiber and 0%-30% of alpinia fiber. The environment-friendly multi-layer composite board is non-toxic, harmless, environment-friendly, capable of forming complementation on properties of hardness, elasticity, corrosion prevention, bacteriostasis and the like, and capable of effectively reducing cost and prolonging service life, when a prepared product is 100g-500g / m 2 in gram weight and 0.2-5mm in thickness, the household-decoration-use environment-friendly multi-layer composite board can directly replace a wallpaper, oil paint, coating and other decoration materials and is directly used, when the prepared environment-friendly board is 1000-5000g / m2 in gram weight and 8-250 mm in thickness, the household-decoration-use environment-friendly multi-layer composite board can be regarded as decoration material and is directly used.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

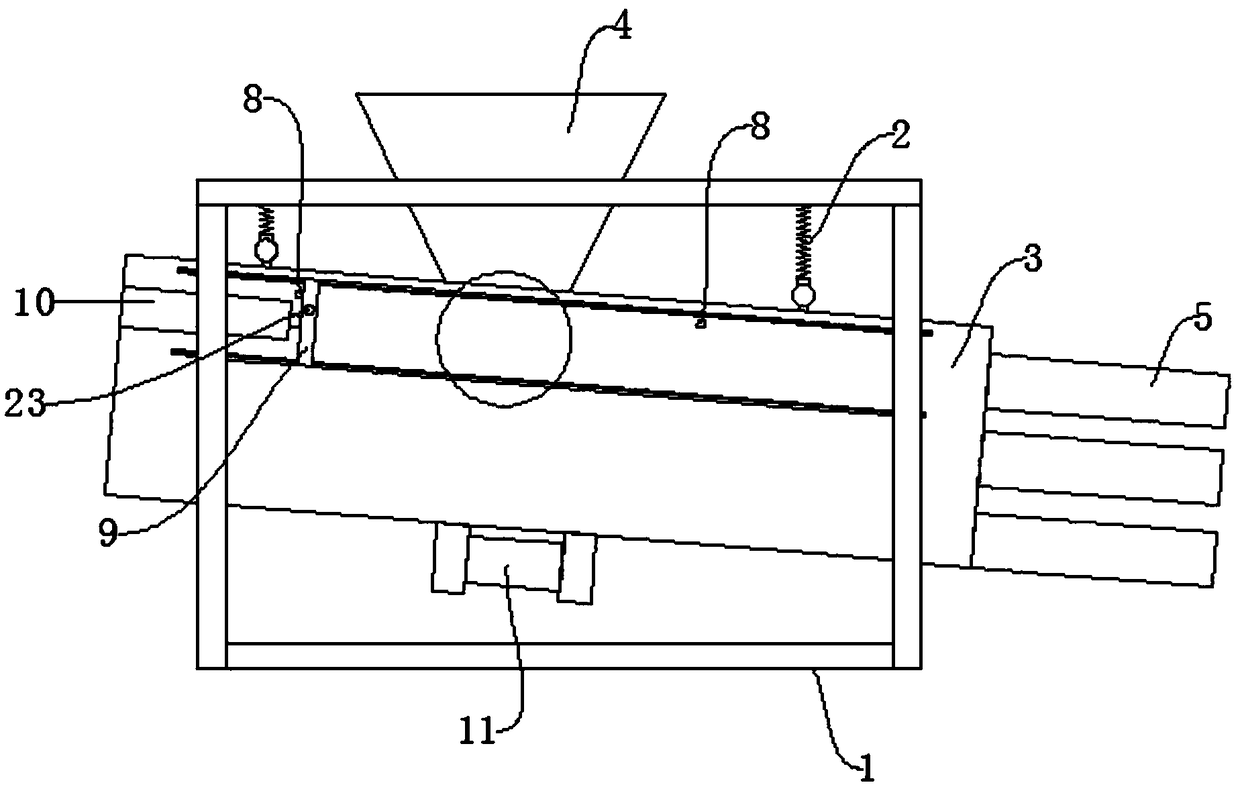

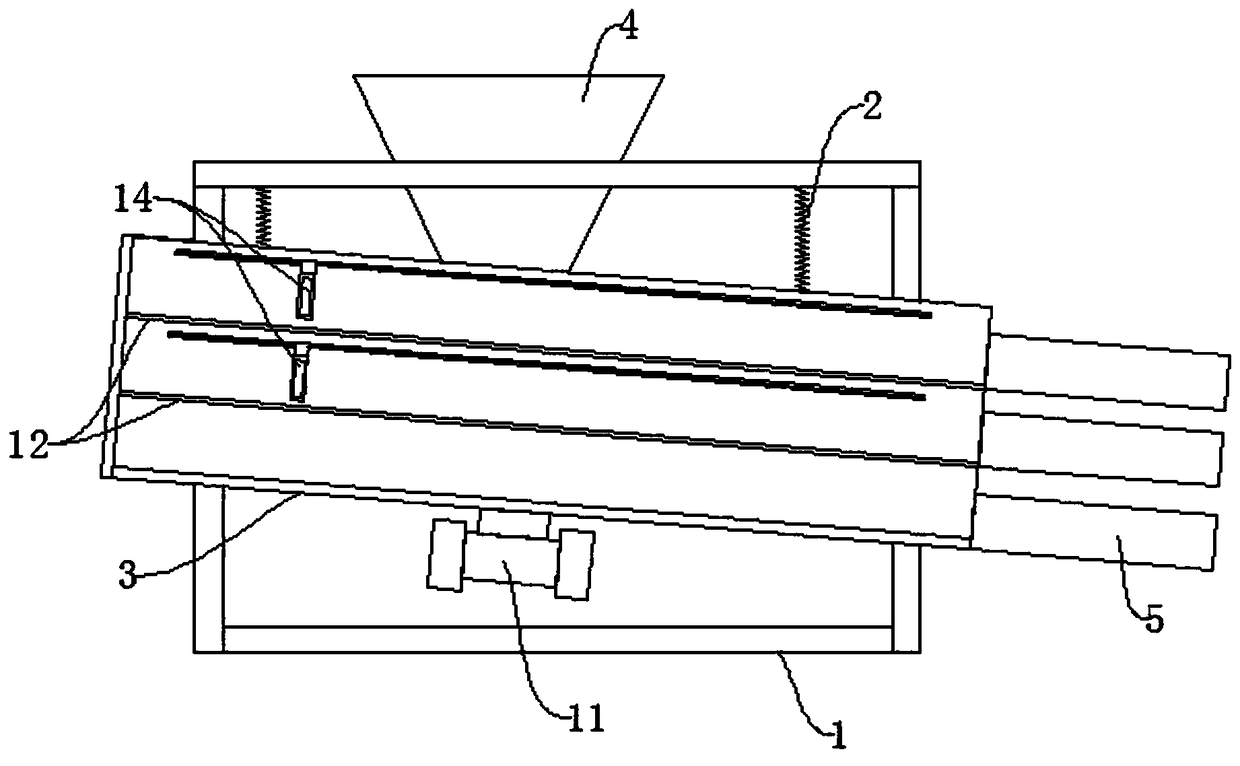

Rapid screening device with flattening function for fodder production

ActiveCN109174618AIncrease the feeding speedIncrease productivitySievingScreeningProduction lineBiochemical engineering

The invention discloses a rapid screening device with a flattening function for fodder production. The rapid screening device comprises a rack. A screening box is mounted on the rack through hanging springs in a hung mode, a feeding hopper is mounted in the middle of the upper end of the screening box, a plurality of discharging hoppers are mounted on the side face of the screening box, and a plurality of vibrating motors are fixedly mounted on the lower surface of the screening box. The rapid screening device has the beneficial effects that the rapid screening device with the flattening function for fodder production can flatten fodder raw materials on a screening plate, thus the falling speed of the fodder screening device can be increased, the corresponding screening speed is increased,the corresponding screening efficiency is improved, the production efficiency of a whole fodder production line can also be further improved, and practicability is good.

Owner:山东利坤生物科技有限公司

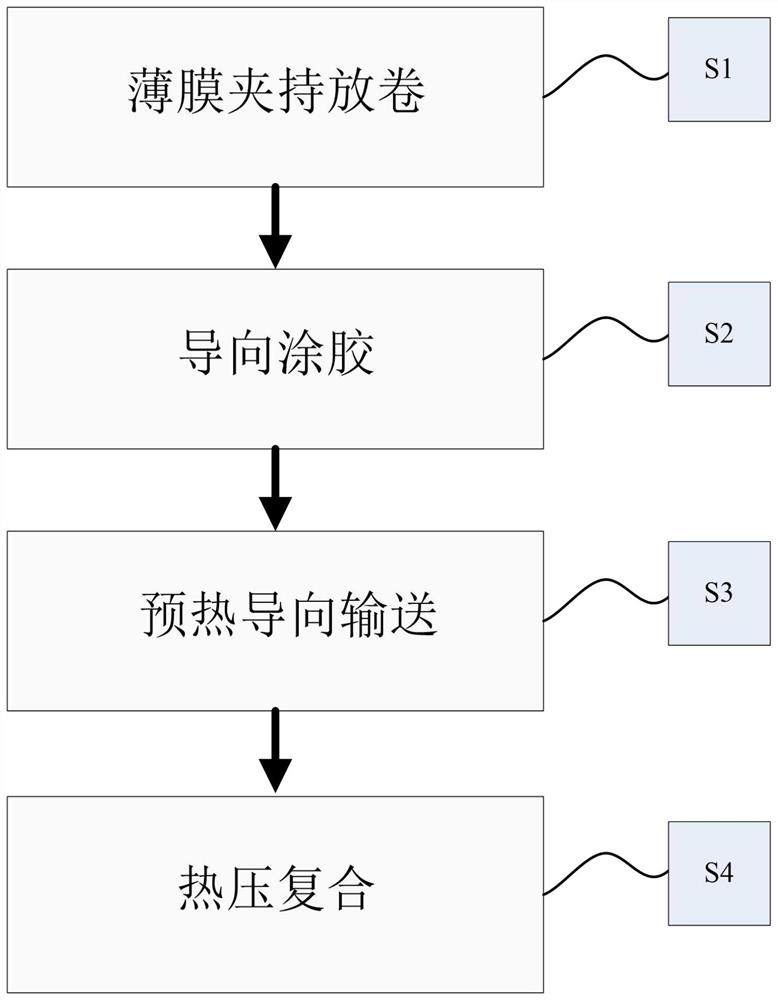

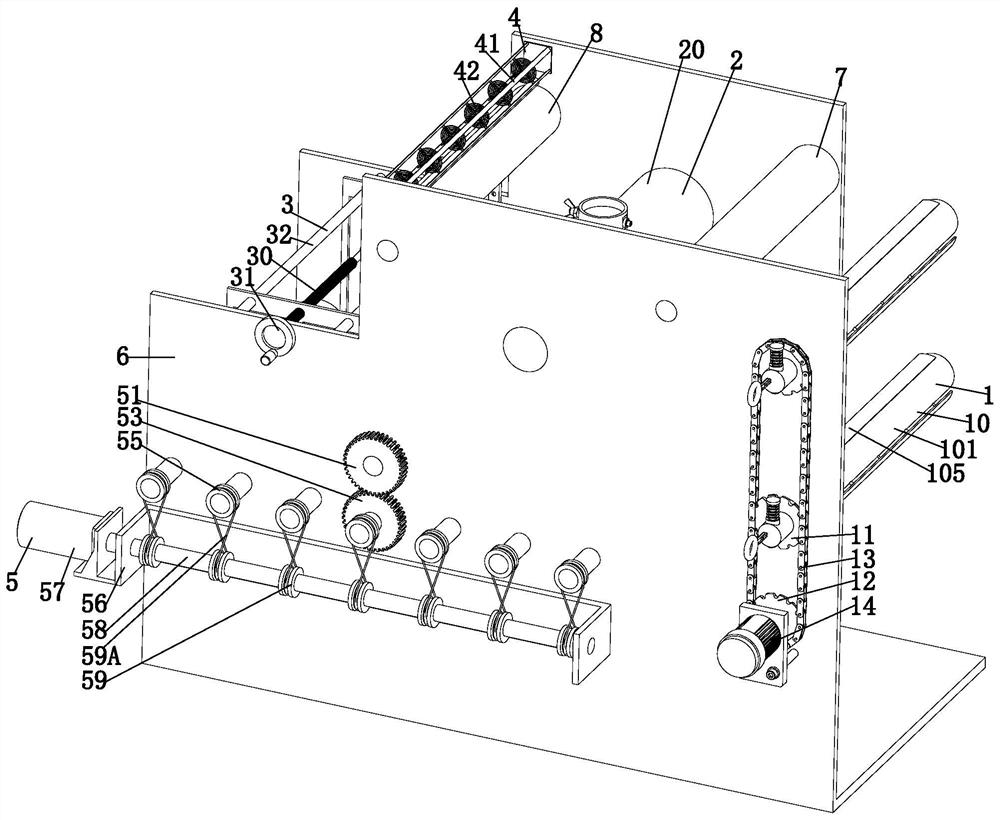

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

Environment-friendly single-layer board for home decoration and manufacture method thereof

ActiveCN103114386AGood moisture absorption and air permeabilityHigh hardnessCovering/liningsNon-woven fabricsFiberEnvironmental resistance

The invention discloses an environment-friendly single-layer board for home decoration and a manufacture method of the environment-friendly single-layer board. The environment-friendly single-layer board is composed of 50-80 wt% of fibrilia, 20-50 wt% of low melting point fiber and 0-30 wt% of Alpinia speciosa fiber. The manufacture method of the environment-friendly single-layer board comprises weighing, pre-opening, mixing, fine-opening, automatic cotton feeding, pre-forming of nets, air laying, upper needling, lower needling, heat bonding in a drying oven, cold rolling, cooling, cutting, inspection, packaging and other procedures. The environment-friendly single-layer board is directly formed by the low melting point fiber and the fibrilia in a composite mode, no other ingredient is added, and therefore the fact that the environment-friendly single-layer board does not contain other harmful chemical substances is guaranteed, and the environment-friendly single-layer board is harmless to a human body and environmental friendly. The fibrilia has good moisture absorption and air permeability properties and is antimicrobial and resistant to mites, thereby being especially suitable for being used as an environment-friendly home decoration material. The environment-friendly single-layer board is light in weight, the gram weight can reach 100-500 grams per square meter, the thickness is in the range of 0.2-5 millimeters, the hardness is high, and therefore the environment-friendly single-layer board can be used for directly replacing wallpaper, oil paint, coatings and other decorating materials and can be directly used on walls, roofs and other places which need decorating.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

High-elasticity natural fiber bed core and preparation method thereof

InactiveCN103054383ASoft touchImprove comfortStuffed mattressesSpring mattressesSurface layerPalm fiber

The invention discloses a high-elasticity natural fiber bed core. The high-elasticity natural fiber bed core comprises at least one intermediate layer and a surface layer arranged on the upper surface or the lower surface of the intermediate layer, wherein each surface layer is a non-woven layer consisting of the following components by weight: 15 to 40 percent of low-melting-point fiber and 60 to 80 percent of raw bamboo fiber; the intermediate layer consists of the following components by weight: 60 to 85 percent of bamboo palm fiber and 15 to 40 percent of low-melting-point fiber; the bamboo palm fiber consists of coconut palm fiber and raw bamboo fiber; and the content ratio of the coconut palm fiber to the raw bamboo fiber is (1-4):1. The invention further discloses a preparation method for the natural fiber bed core. The preparation method comprises the following steps: preparing the upper surface layer, the lower surface layer and the intermediate layer respectively; sequentially paving the layers; drying by using a drying oven; performing cold rolling; cooling; cutting; checking; and packaging. According to the natural fiber bed core and the preparation method thereof, the technical problems that the conventional mattress is easy to layer and break, has low elasticity and low air permeability, and is mildewed and verminous are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Environment-friendly composite board for home decoration and preparation method thereof

ActiveCN103112209AGood moisture absorption and air permeabilityHigh hardnessSynthetic resin layered productsFiberEnvironmental resistance

The invention discloses an environment-friendly composite board for home decoration and a preparation method thereof. The environment-friendly composite board is composed of a base board and a PE (polyethylene) film arranged on the surface of the base board, wherein the base board comprises the following components in percentage by weight: 50-80% of jute fiber, 20-50% of low-melting-point fiber and 0-30% of Alpinia zerumbet fiber. According to the environment-friendly composite board for home decoration, the base board is prepared by compounding low-melting-point fibers, jute fibers and Alpinia zerumbet fibers, the food grade colored PE film is covered on the base board, and no other components are added, thereby ensuring that the product is free of other harmful chemical substances and causing no harm to the body; and meanwhile, the jute fibers bring favorable moisture absorption and air permeability, and have bacterium resistance and mite prevention effects. The environment-friendly board is light in weight and high in hardness, can be used instead of wallpaper, paint and other decorative materials, and can be directly used in places to be decorated, such as walls, roofs and the like. The preparation method of the environment-friendly composite board is simple in procedures, convenient to operate and easy to realize industrialization; and the gram weight of the prepared product can be up to 100-300 g / m<2>, and the thickness is 0.3-5 mm.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com