Vacuum deposition device

An evaporation and vacuum technology, which is applied in the field of vacuum evaporation equipment, can solve the problems of inability to correctly control the evaporation speed, uneven evaporation of the evaporation body, and inability to form an evaporation film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

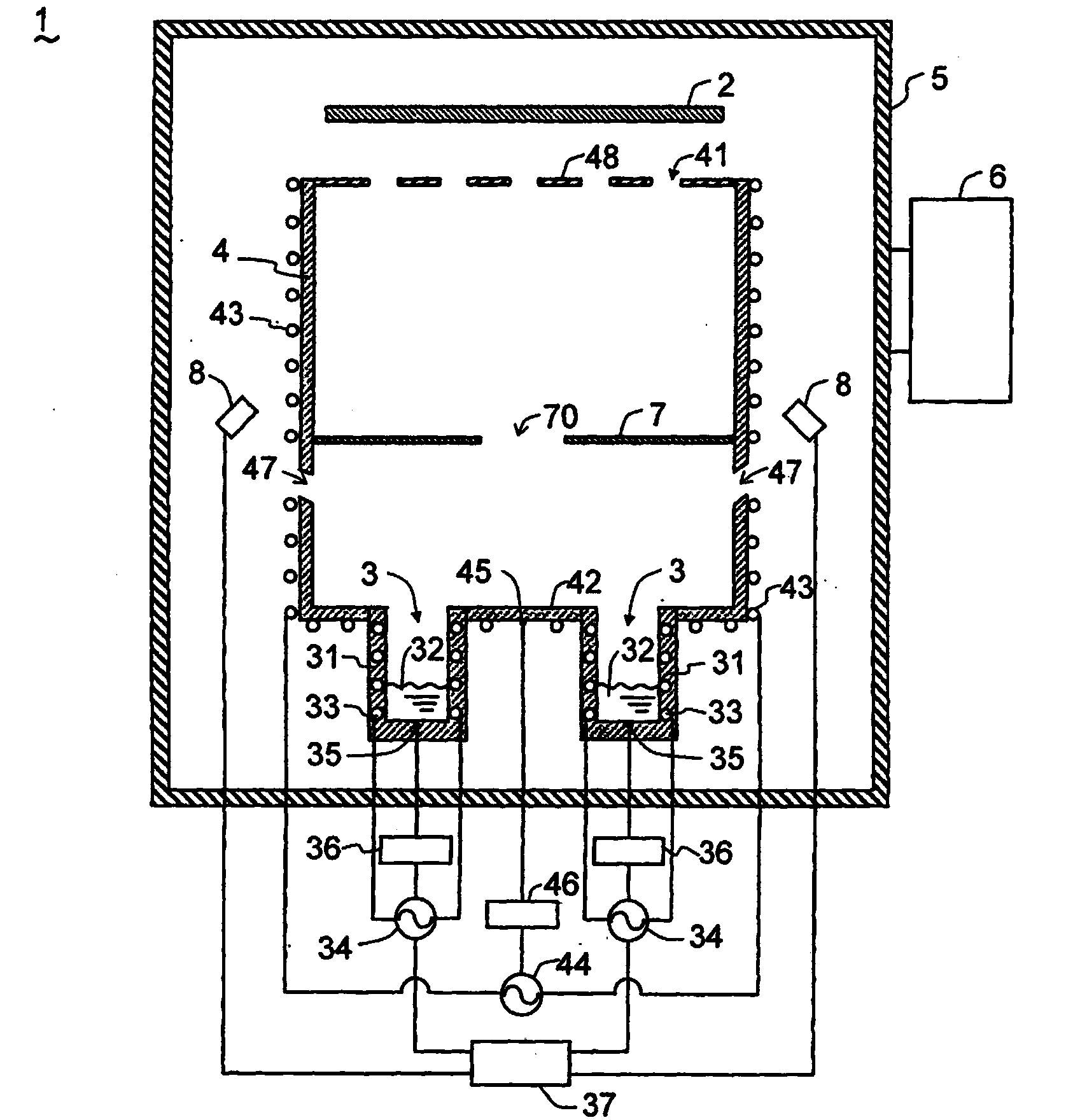

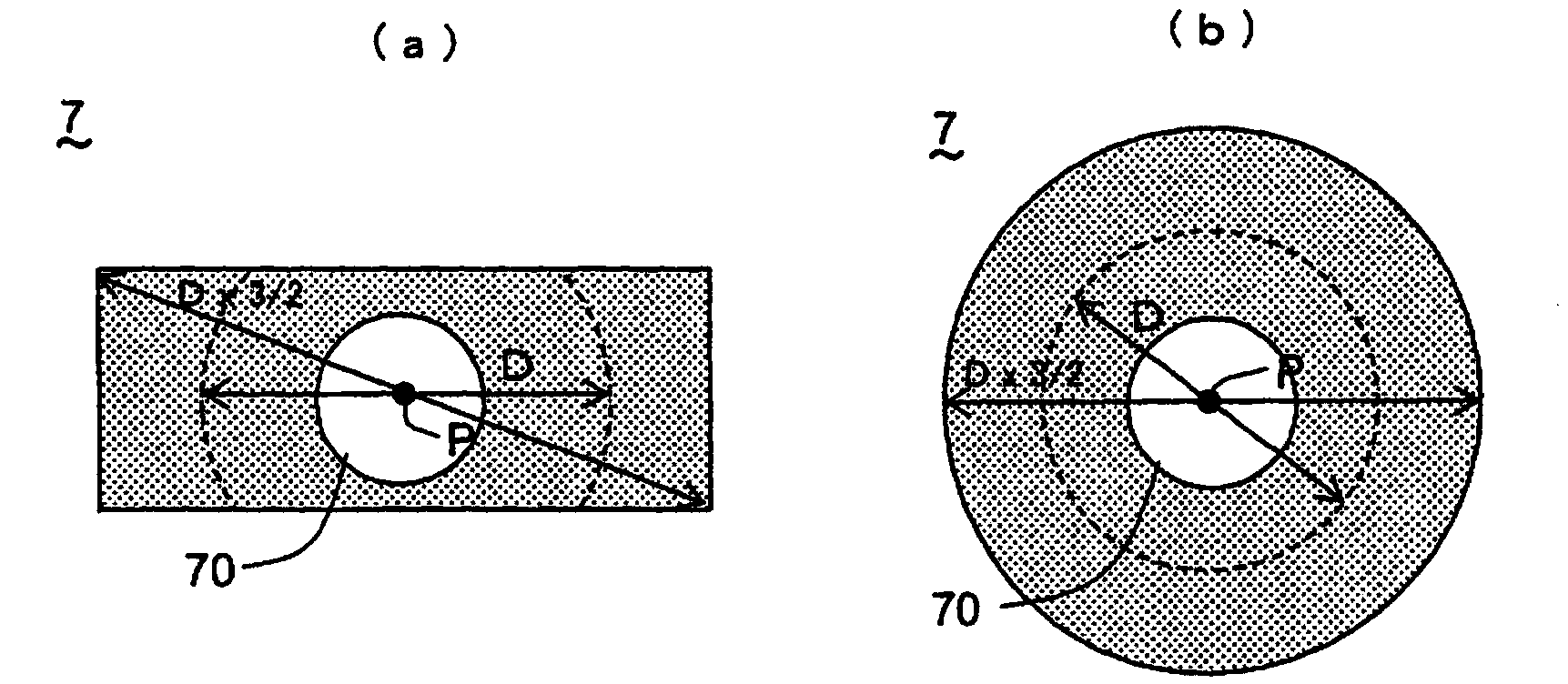

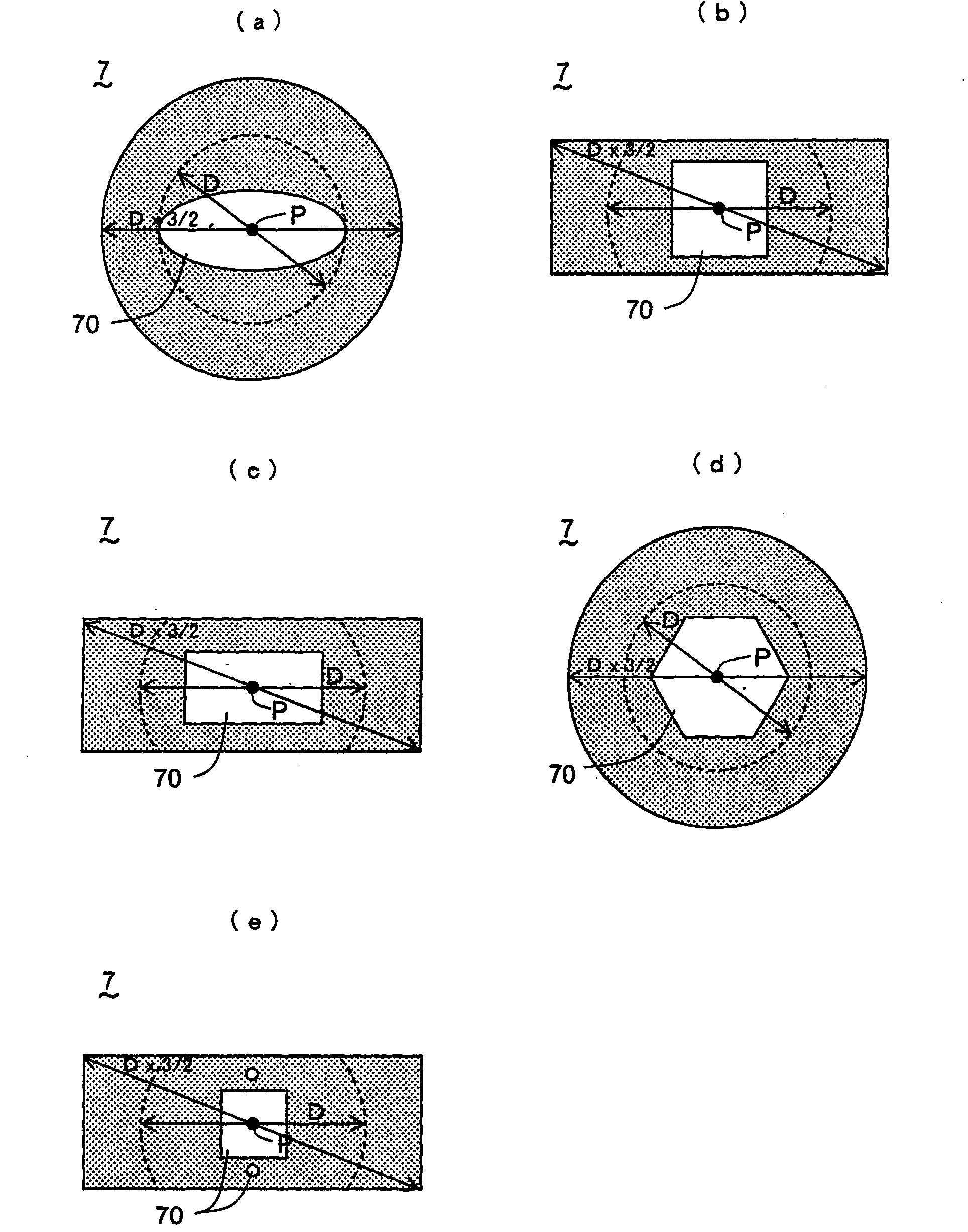

[0038] For the vacuum evaporation device of the first embodiment of the present invention, refer to Figure 1 to Figure 3 Be explained. like figure 1 As shown, the vacuum evaporation device 1 of the present embodiment is provided with a plurality of evaporation sources 3 for evaporating various materials on the evaporation target 2 , and a plurality of evaporation sources 3 and the evaporation target 2 are connected to each other. A cylindrical body 4 surrounded by a space and having an open surface on the vapor-deposited body 2 side. Furthermore, a vacuum chamber 5 is provided which makes the space in which the vapor deposition object 2, the evaporation source 3, and the cylindrical body 4 are arranged to be in a vacuum state. The vacuum chamber 5 is configured to be decompressed into a vacuum state by exhausting the vacuum pump 6 .

[0039] The cylindrical body 4 has an opening surface 41 at one end, and a correction plate 48 for flow rate control described later is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com