Environmental protection board for interior decoration and preparation method thereof

An interior decoration and environmental protection technology, applied in the field of decorative materials, can solve problems such as the use of decorative materials, and achieve the effects of enhancing anti-corrosion performance, convenient operation, and improving selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

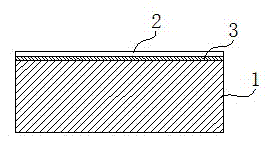

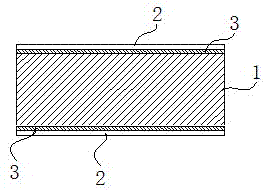

[0029] The environment-friendly board for interior decoration is composed of a substrate 1, a non-woven fabric layer 3 on one side, and a PE film 2. Substrate 1 is composed of 50% flax by weight and 50% ES fiber by weight (skin-core structure, the skin is PE polyethylene, the melting point range is 125-135°C; the core is PP polypropylene, the melting point range is 145-165°C) .

[0030] The method for preparing the above-mentioned environmental protection board for interior decoration: weighing each component of the substrate according to the required ratio, pre-opening, mixing, fine opening, automatic cotton feeding, pre-forming, air-laid, upper acupuncture, Needle punching to obtain the substrate, put non-woven fabric on it, oven thermal bonding (170°C, 20min), cold rolling (0°C), cooling, and food-grade colored PE film (contact thermal bonding, 150°C) , Cutting to obtain the environmental protection board, it can be inspected and packaged; among them, the web forming speed...

Embodiment 2

[0033] The environment-friendly board for interior decoration is composed of a substrate 1, a non-woven fabric layer 3 on one side, and a PE film 2. Substrate 1 is composed of 80% jute by weight and 20% by weight PET bicomponent fiber (the skin is PET polyester fiber with a melting point of 110-120°C; the core is PET polyester fiber with a melting point of 260°C).

[0034] The method for preparing the above-mentioned environmental protection board for interior decoration: weighing each component of the substrate according to the required ratio, pre-opening, mixing, fine opening, automatic cotton feeding, pre-forming, air-laid, upper acupuncture, Needle punching to obtain the substrate, put the non-woven fabric on it, oven thermal bonding (230°C, 0.5min), cold rolling (30°C), cooling, and food-grade colored PE film (contact thermal bonding, 230°C ), cut to obtain environmental protection board, and then inspect and pack it; among them, the web forming speed is 1m / min; the needl...

Embodiment 3

[0037] The environment-friendly board for interior decoration is composed of a substrate 1, a non-woven fabric layer 3 on one side, and a PE film 2. The substrate 1 is composed of 50% by weight of sisal, 20% by weight of PLA fiber (melting point range 150-160°C), and 30% by weight of peach fiber.

[0038] The method for preparing the above-mentioned environmental protection board for interior decoration: weighing each component of the substrate according to the required ratio, pre-opening, mixing, fine opening, automatic cotton feeding, pre-forming, air-laid, upper acupuncture, Needle punching to get the substrate, put the non-woven fabric on it, oven thermal bonding (210°C, 5min), cold rolling (0°C), cooling, and food-grade colored PE film (contact thermal bonding, 170°C) , Cutting to obtain the environmental protection board, just carry out inspection and packaging; among them, the web forming speed is 1-20m / min; the acupuncture density is 30 pricks / cm 2 .

[0039] The per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com