Multi-layer insulated glass unit comprising a low cte glass layer

A technology of insulating glass and glass layers, applied in parallel glass structures, windows/doors, building components, etc., can solve the problems of increasing the total thickness of IGU, increasing the manufacturing cost of IGU, and reducing the optical quality of IGU

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

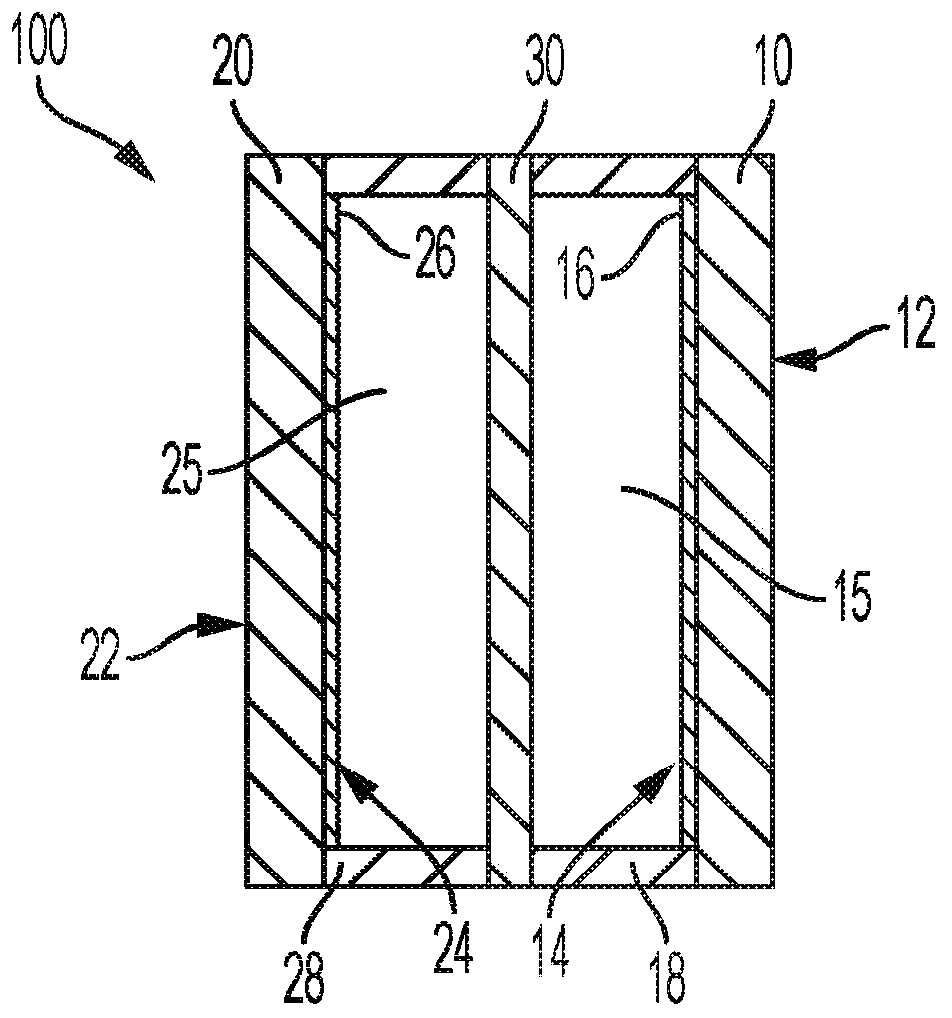

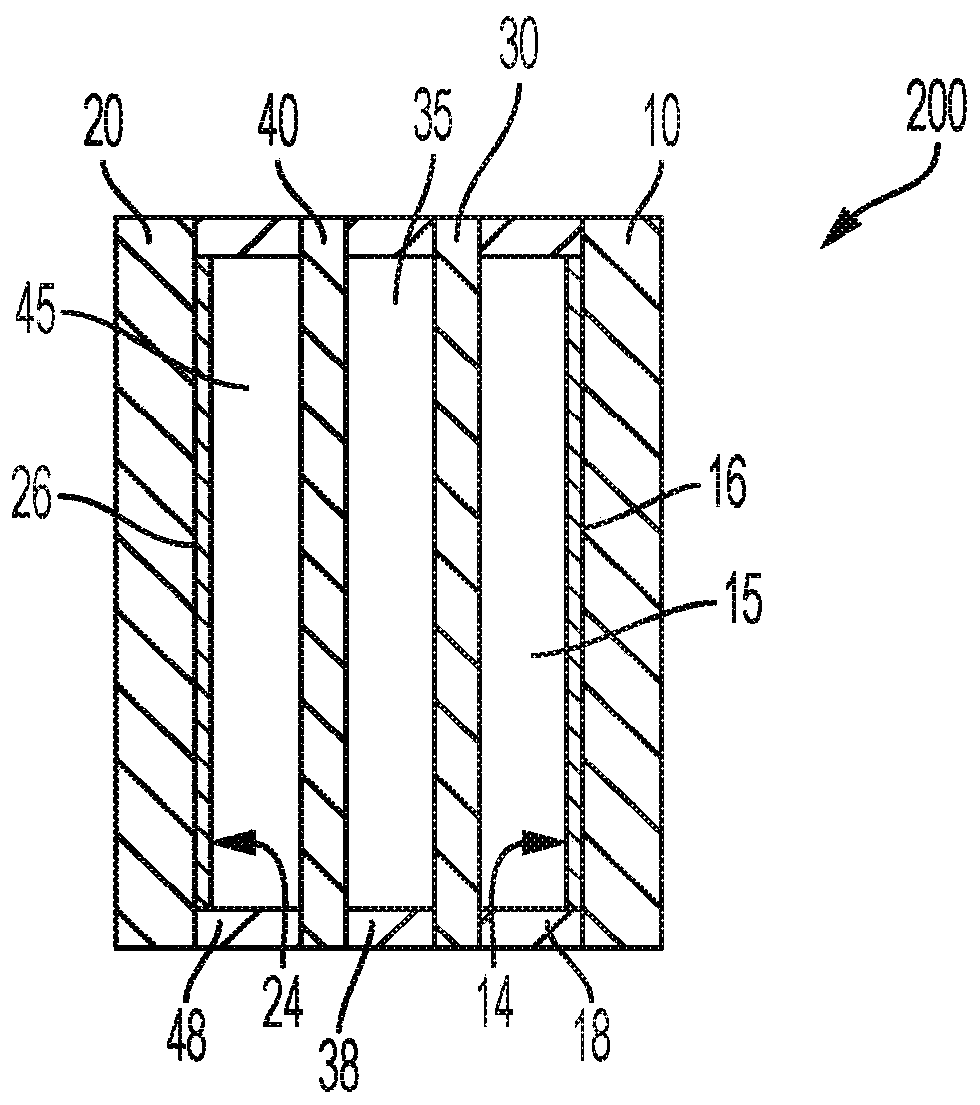

[0019] will now refer to Figure 1-5 Discussing various embodiments of the present disclosure, Figure 1-5 Exemplary embodiments of IGUs and components, features or properties thereof are illustrated. The following general description is intended to provide a general overview of the claimed device, and various aspects will be discussed more particularly throughout the disclosure with reference to non-limiting described embodiments which, in the context of the present disclosure, can be compared with each other. exchange.

[0020] Disclosed herein is an insulating glass unit comprising a first ply of glass, a second ply of glass and a third ply of glass disposed between the first ply of glass and the second ply of glass, defined between the first ply of glass and the third ply of glass A first sealed interstitial space between, and a second sealed interstitial space defined between the second glass layer and the third glass layer, wherein the third glass layer has a coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap