Axial-flow type efficient mixer

A mixer, axial flow technology, applied in the directions of fluid mixers, mixers, chemical instruments and methods, can solve the problems of reducing efficiency and product quality, difficult to achieve high-efficiency simultaneous mixing of three raw materials, etc. fully mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

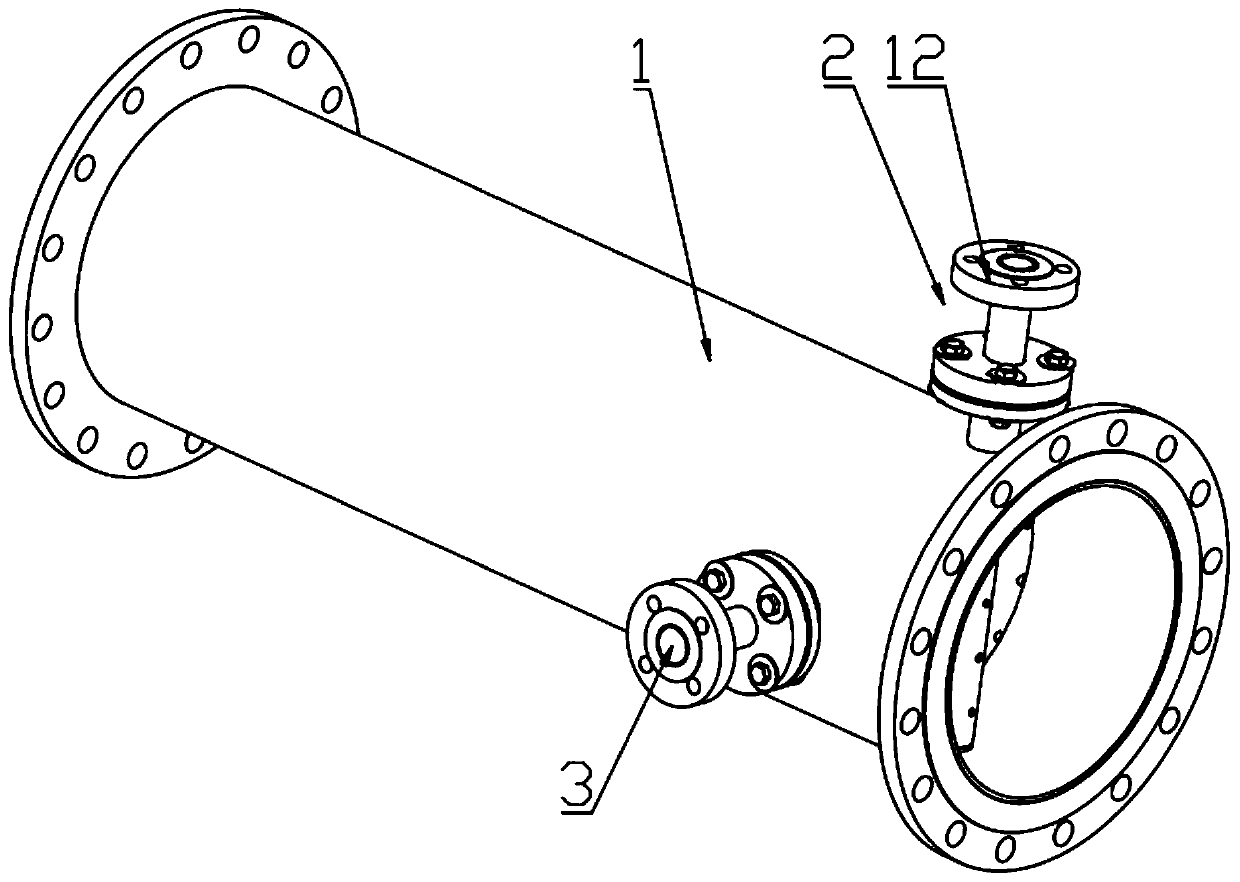

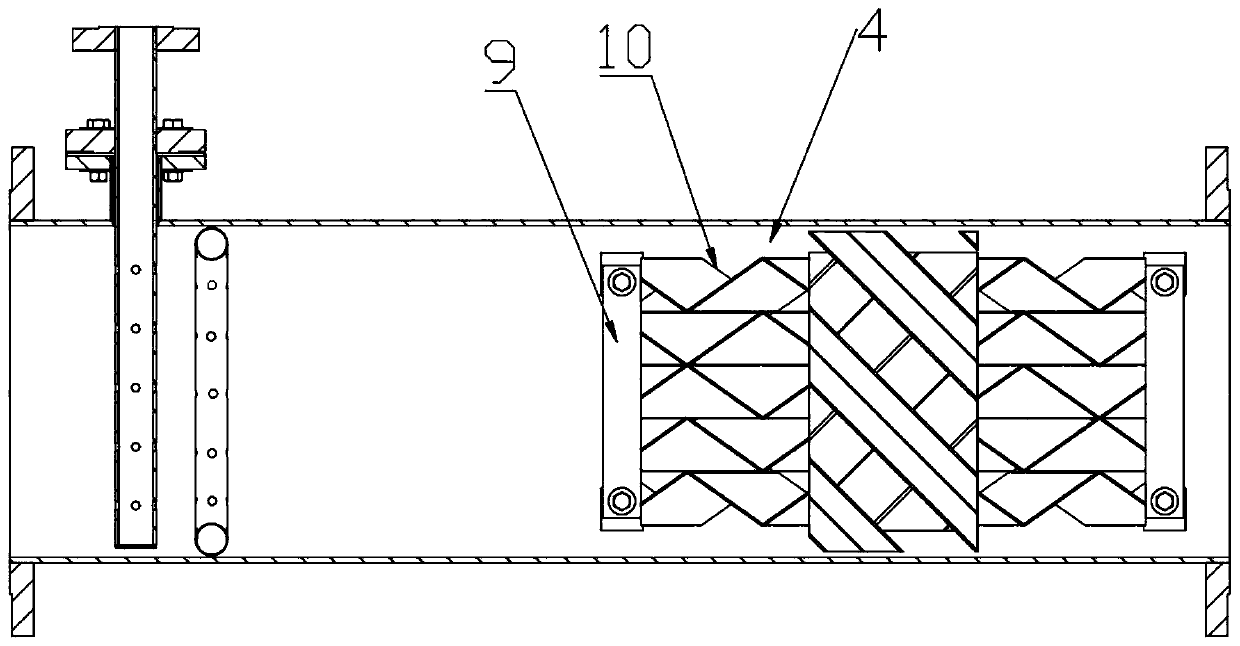

[0017] Such as Figure 1-5 As shown, an axial-flow high-efficiency mixer includes a mixing pipeline 1, a first feeding assembly 2, a second feeding assembly 3 and a flow guide assembly 4, and the first feeding assembly 2 and the second feeding assembly 3 are located at The front end of the mixing pipeline 1, the flow guide assembly 4 is arranged on the rear side of the mixing pipeline 1;

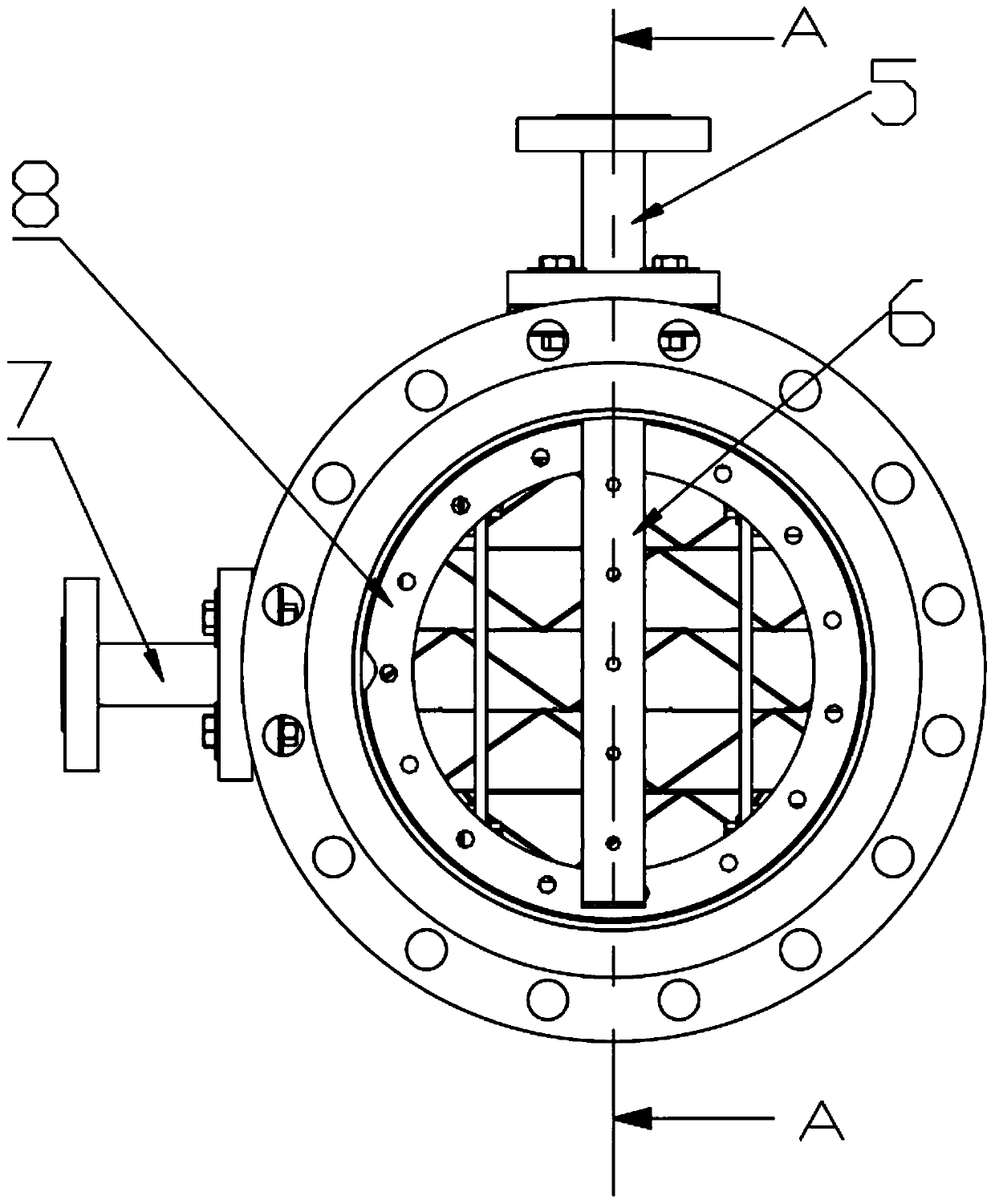

[0018] The first feeding assembly 2 includes a first inlet pipe 5 arranged outside the mixing pipe 1 and a first release pipe 6 arranged on the inner wall of the mixing pipe, and the first release pipe 6 passes through the mixing pipe vertically 1, the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com