Novel material sorting control system

A control system and material technology, applied in sorting, electrical program control, program control in sequence/logic controllers, etc., can solve the problems of slow speed and low precision, and achieve simple and accurate control, flexible settings, The effect of improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained and illustrated by specific embodiments below.

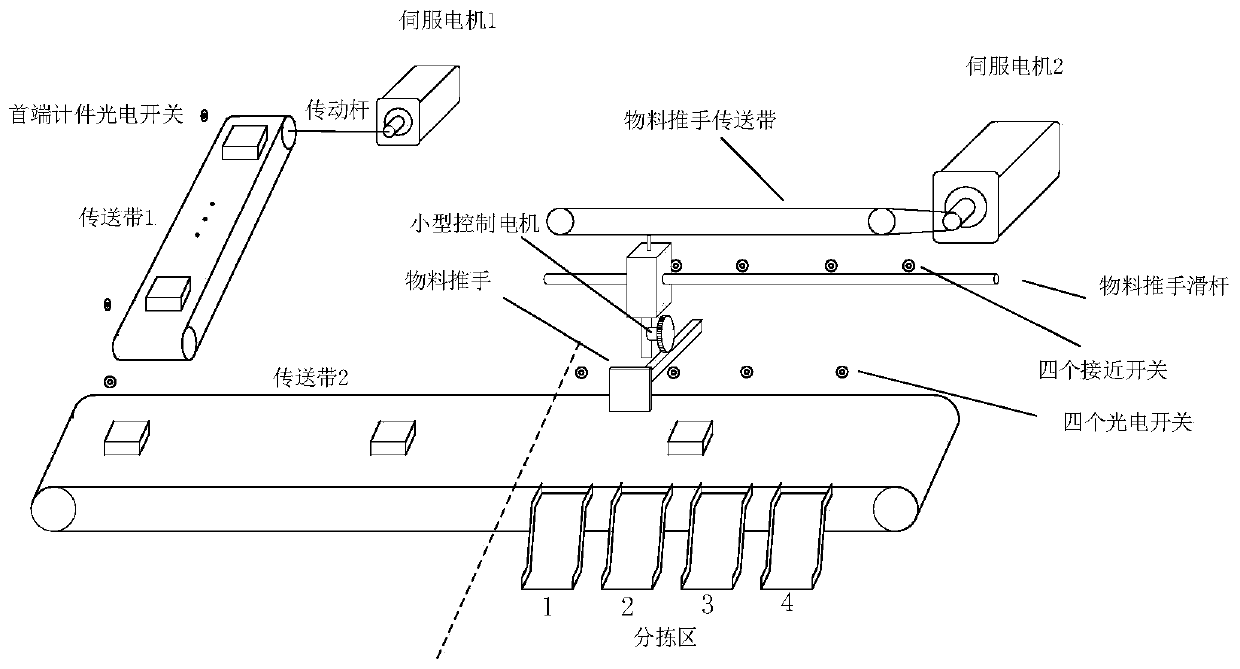

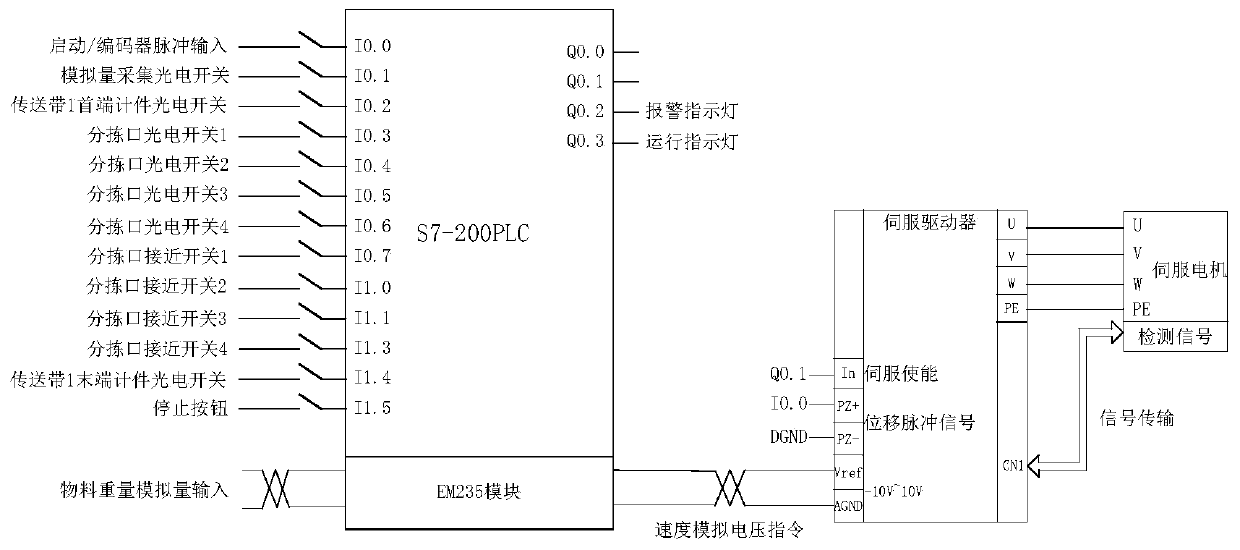

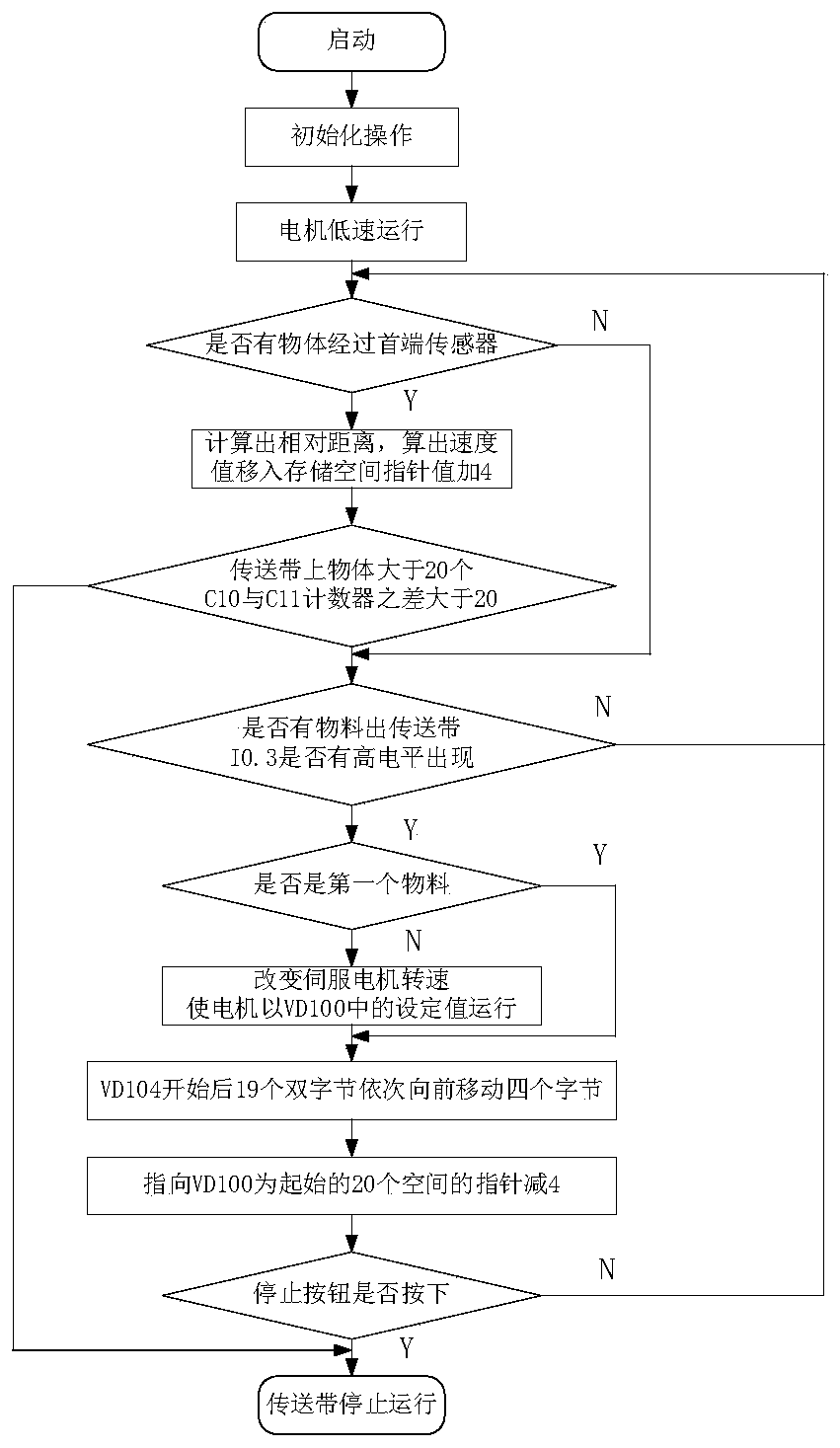

[0020] The present invention is mainly composed of a monitoring device, a transmission device, a central processing device, etc., please refer to figure 1 and figure 2 . The present invention mainly includes a power supply module, a PLC module, a servo motor control system operating independently, a weight detection module, a servo motor module, a servo driver module, a transmission device, a conveyor belt 1, a conveyor belt 2, a material pusher, a material pusher conveyor belt, and a sorting port slide. , Material pusher slider, small control motor, proximity switch and photoelectric sensor switch. The present invention adopts two servo drives and servo motors to drive the horizontal movement of the conveyor belt 1 and the material pusher respectively, and the conveyor belts 1 and 2 cooperate with each other so that the materials can enter the sorting area at equal dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com