Deformed tooth and machining process of aero-engine driven by gradient memory alloy

An aero-engine, memory alloy technology, applied in the direction of engine components, machine/engine, additive processing, etc., to achieve the effect of reasonable structure and shape, reducing airflow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

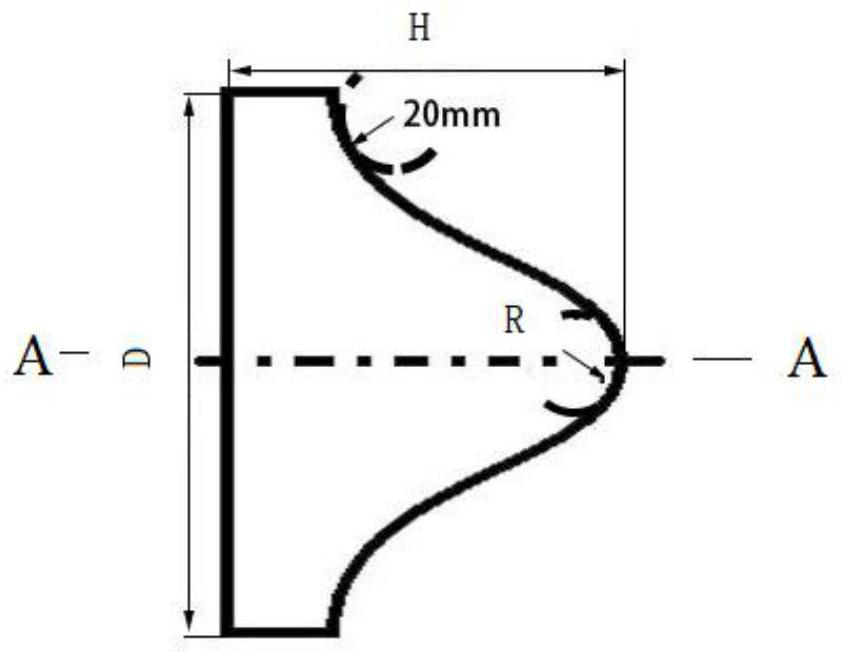

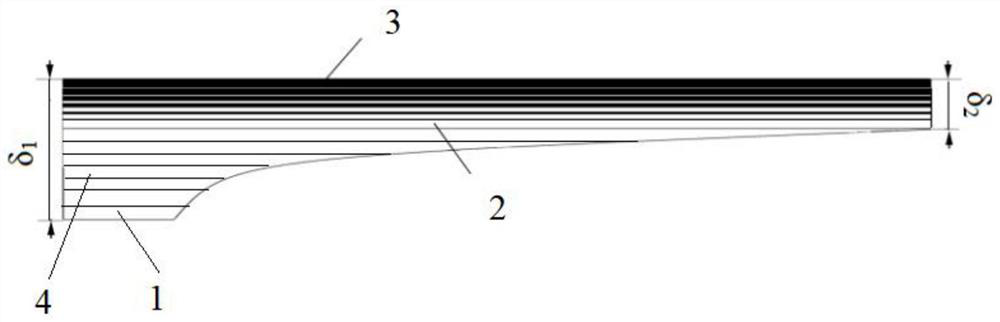

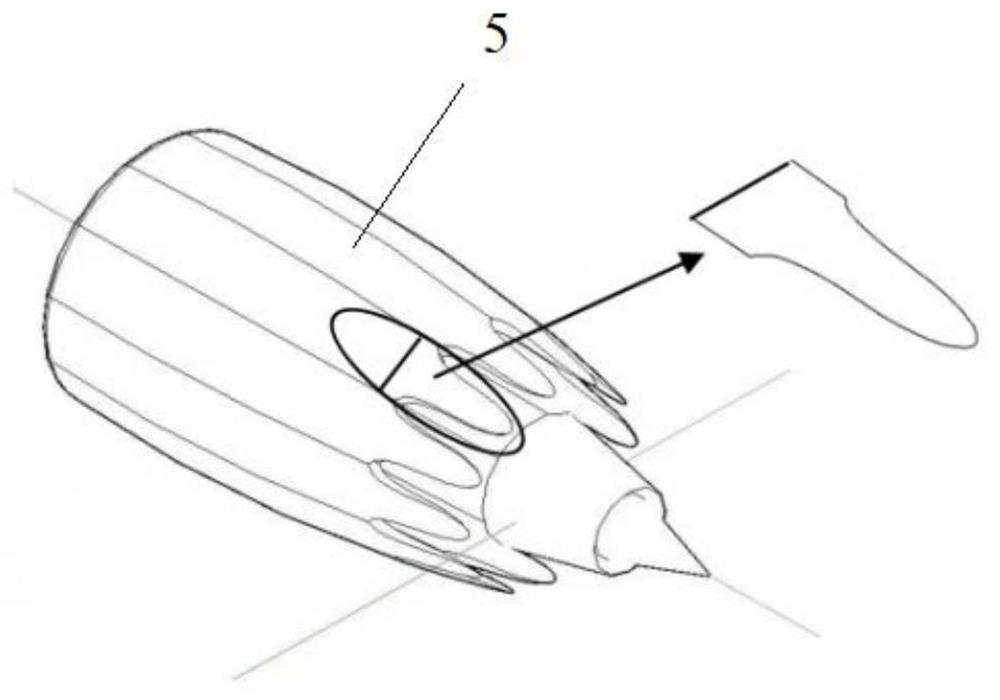

[0030] An aeroengine deformable tooth driven by gradient memory alloy, such as figure 1 As shown, it includes a toothed body. The toothed body includes an inner substrate 1, an outer substrate 3 and several intermediate substrates 2. The inner substrate is pure SMA powder material, and the outer substrate is pure aluminum alloy. Powder material, the intermediate layer substrate is mixed with aluminum alloy powder and SMA powder in proportion to form a mixed material, and the mixed material is integrally formed with pure SMA powder material and pure aluminum alloy powder material by laser cladding and layer-by-layer sintering. The volume ratio of the SMA powder of the mixed material of the sheet increases linearly from the outside to the insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com