Positioning clamp for U-shaped bending plate

A technology for positioning fixtures and bending plates, which is applied in metal processing and other directions, and can solve problems such as processing errors and slow processing speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

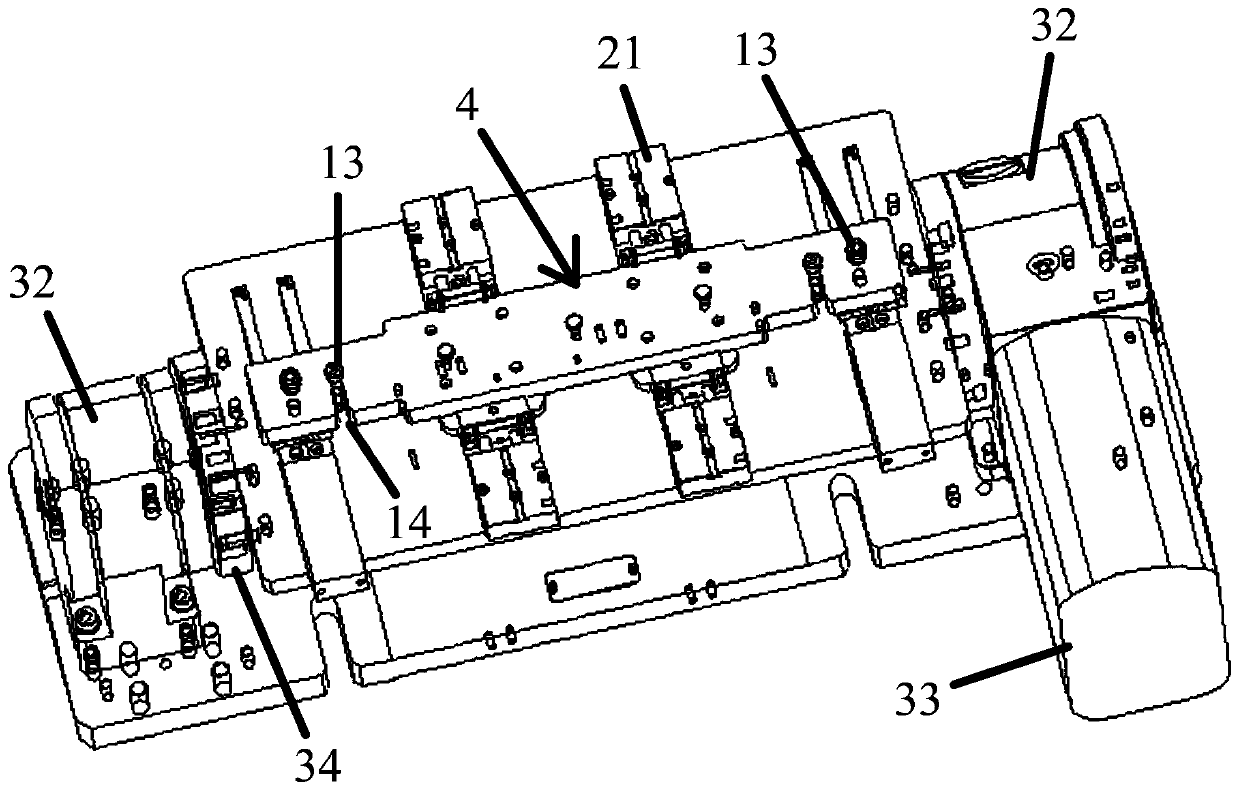

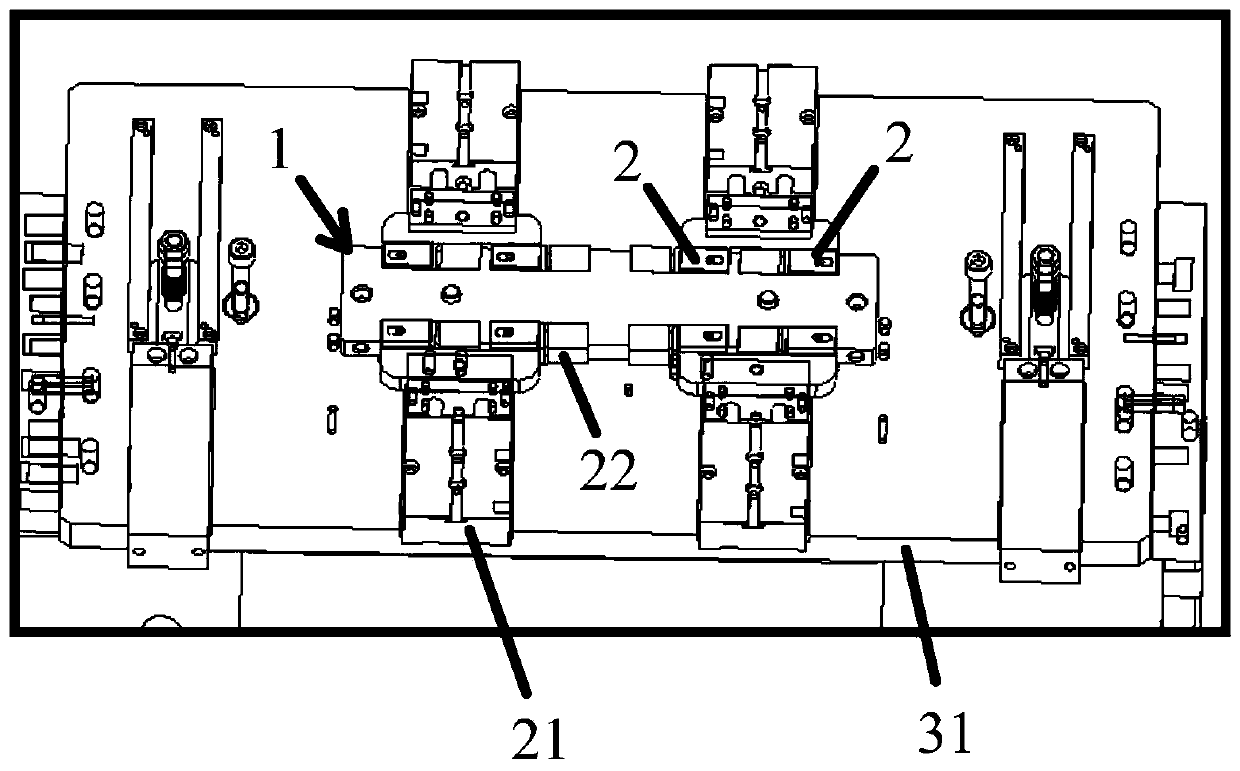

[0057] A positioning fixture for U-shaped bending plates provided in this embodiment, such as Figure 1 to Figure 3 shown, which includes:

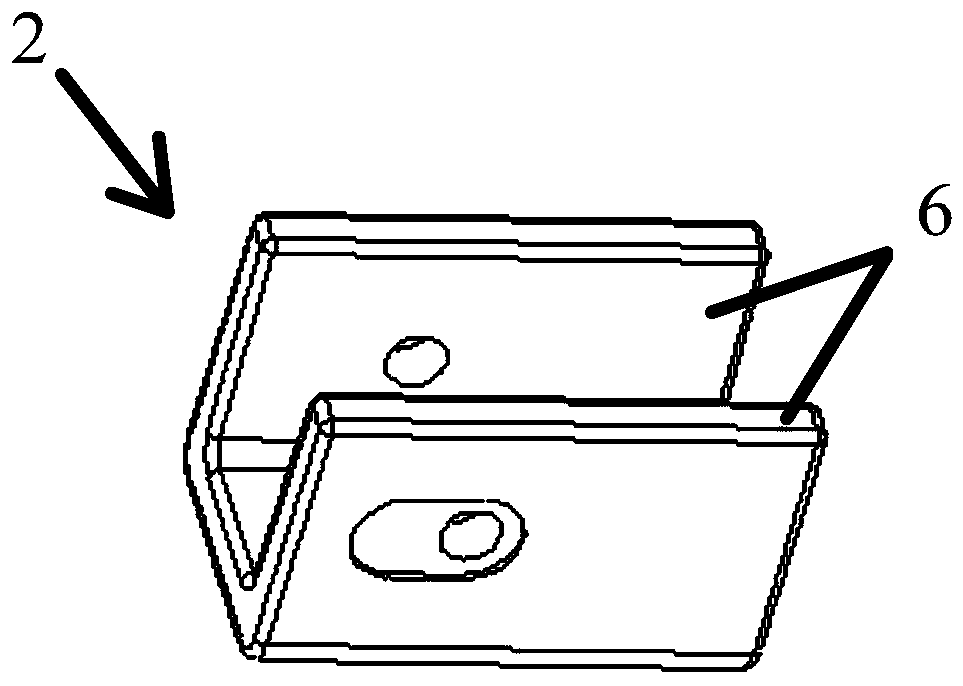

[0058] The clamping fixture 1 is arranged on the fixed base plate 31; the outer contour edge of the clamping fixture 1 is provided with a clamping part 3 for inserting the U-shaped bending plate 2, and the clamping part 3 is for accommodating The groove of the U-shaped bending plate 2; there is a sliding gap arranged along the thickness direction of the clamping fixture 1 between the groove and the U-shaped bending plate 2;

[0059] rotating mechanism, such as Figure 5 As shown, it is connected with the clamping fixture 1 to drive the clamping fixture 1 to rotate on the same horizontal plane to convert the front and back positions of the clamping fixture 1; the rotating mechanism includes: respectively arranged on The fixed seats 32 at both ends of the fixed base plate 31, and the fifth drive source 33; the fixed base 32 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com