Powdering device for mold of projecting tile of eaves for house building

A construction and mold technology, applied in construction, supply equipment, building construction, etc., can solve the problems of cumbersome operation process, manpower consumption, and low work efficiency, and achieve the effects of simple operation, improved work efficiency, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] first implementation

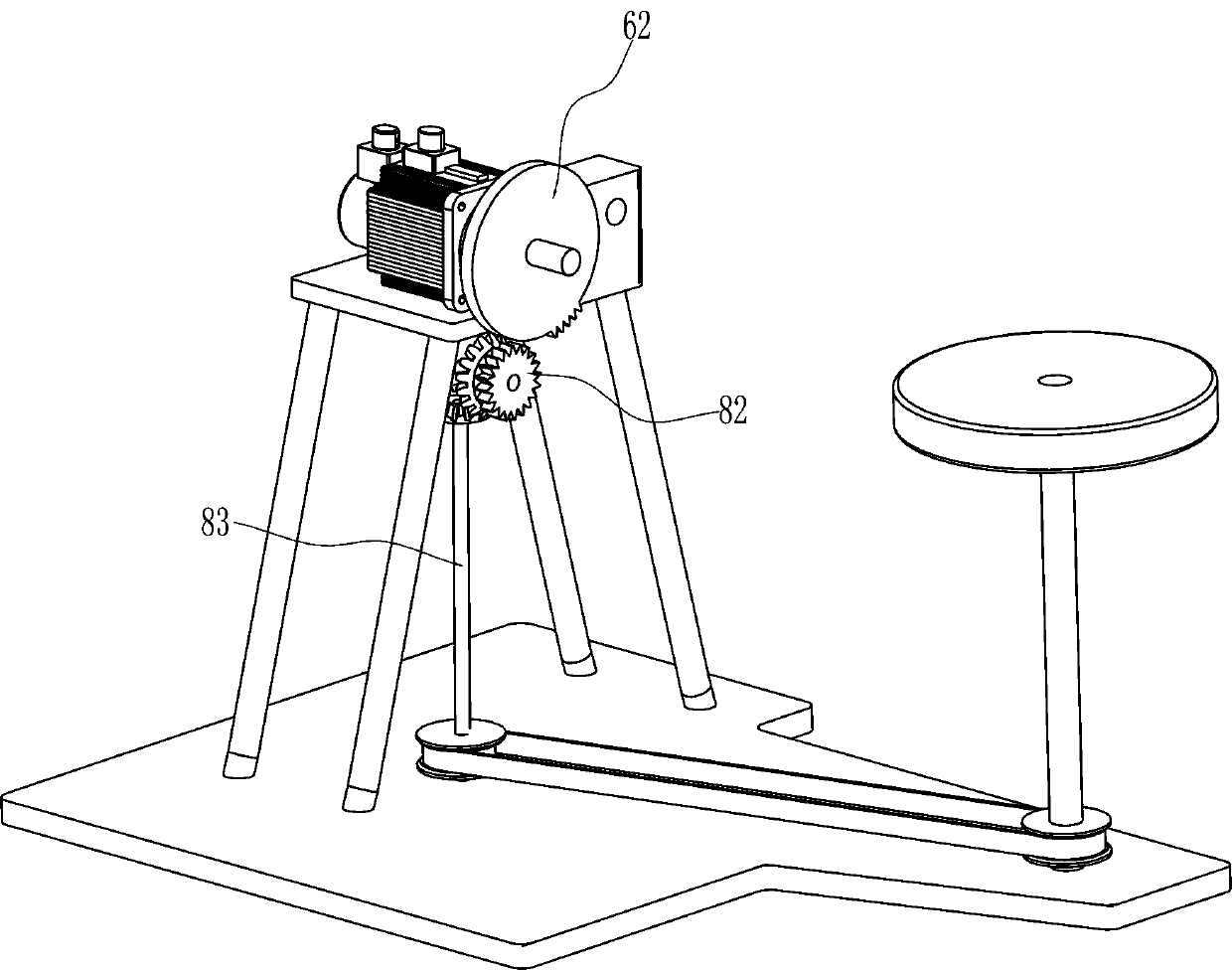

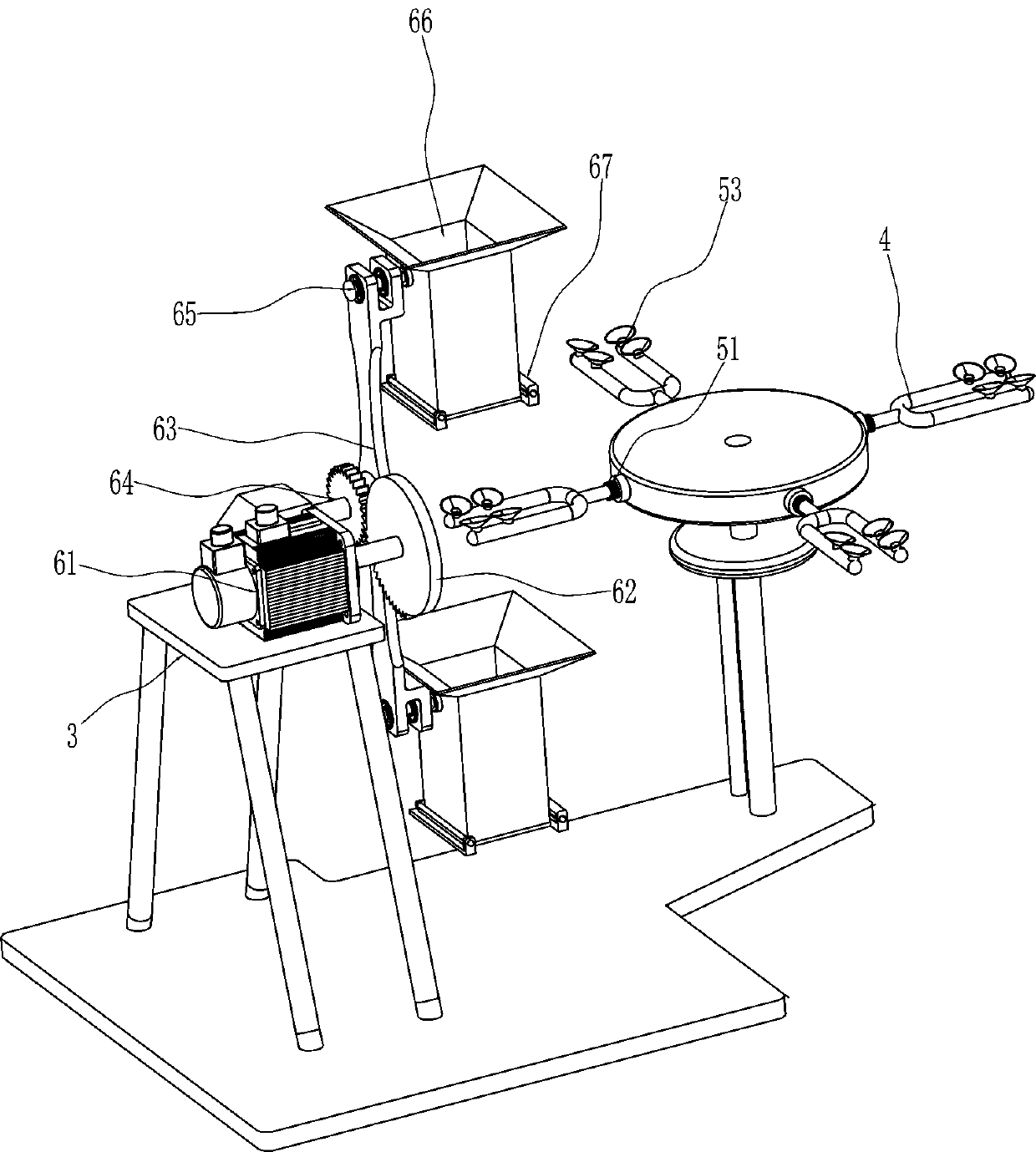

[0026] A kind of dripping tile mold powder feeding device for building construction, such as Figure 1-3 As shown, it includes a base 1, a turntable 2, a fixed frame 3 and a mounting frame 4. The right side of the top of the base 1 is rotatably connected to the turntable 2, and the left side of the top of the base 1 is connected to the fixed frame 3. The outer sides of the turntable 2 are evenly spaced along the circumferential direction. Four mounting frames 4 are connected, and also include a placement component 5 and a material dumping component 6 , a positioning component 5 is provided between the mounting frame 4 and the turntable 2 , and a material dumping component 6 is provided on the fixed frame 3 .

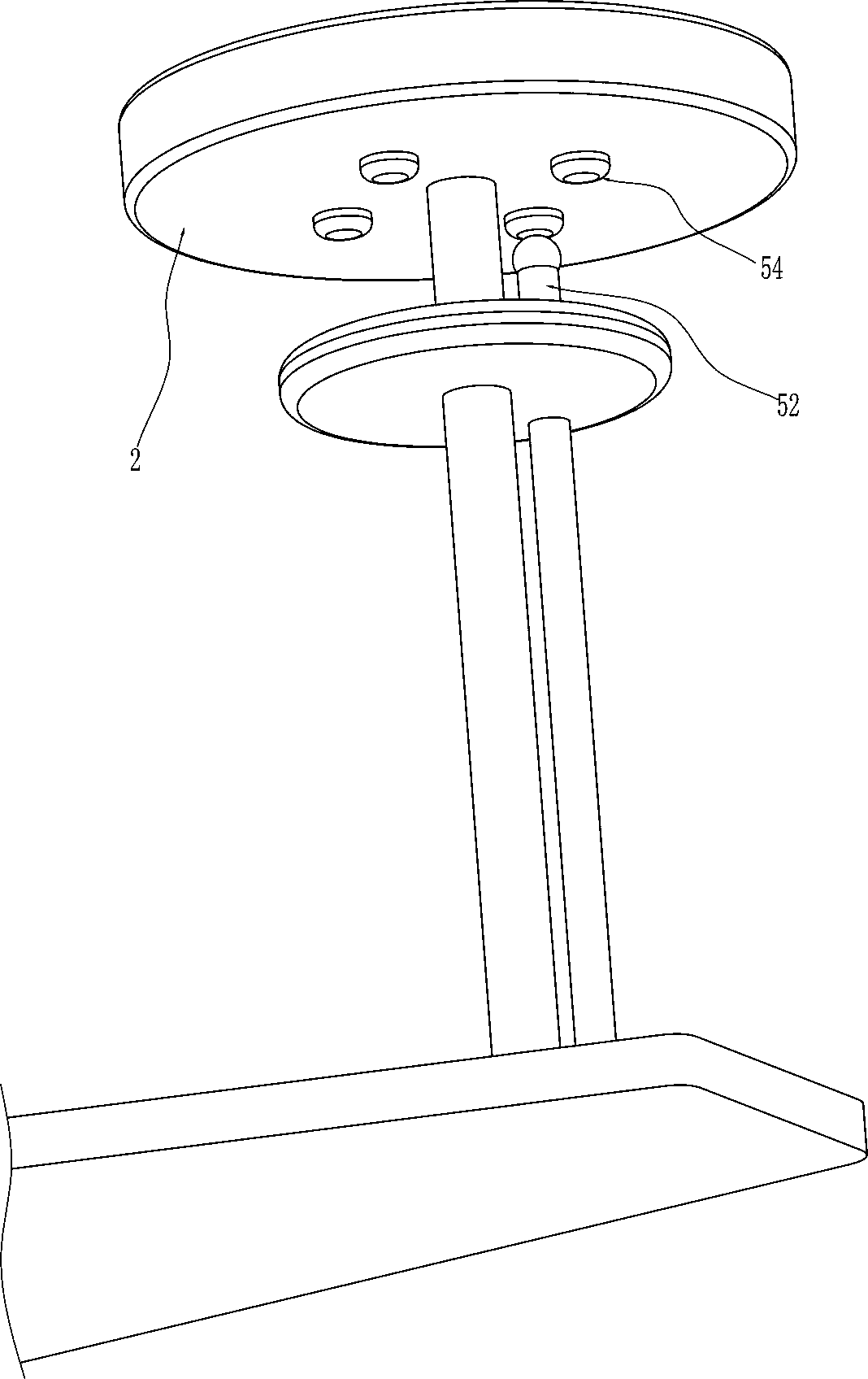

[0027] The placement assembly 5 includes a torsion spring 51, a contact rod 52, a vacuum chuck 53 and a first cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com