Mask sheet forming machine

A technology for forming machines and masks, which is applied to household components, tools for sewing clothes, household appliances, etc., can solve the problems of reducing production efficiency and increasing labor costs, and achieve the effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

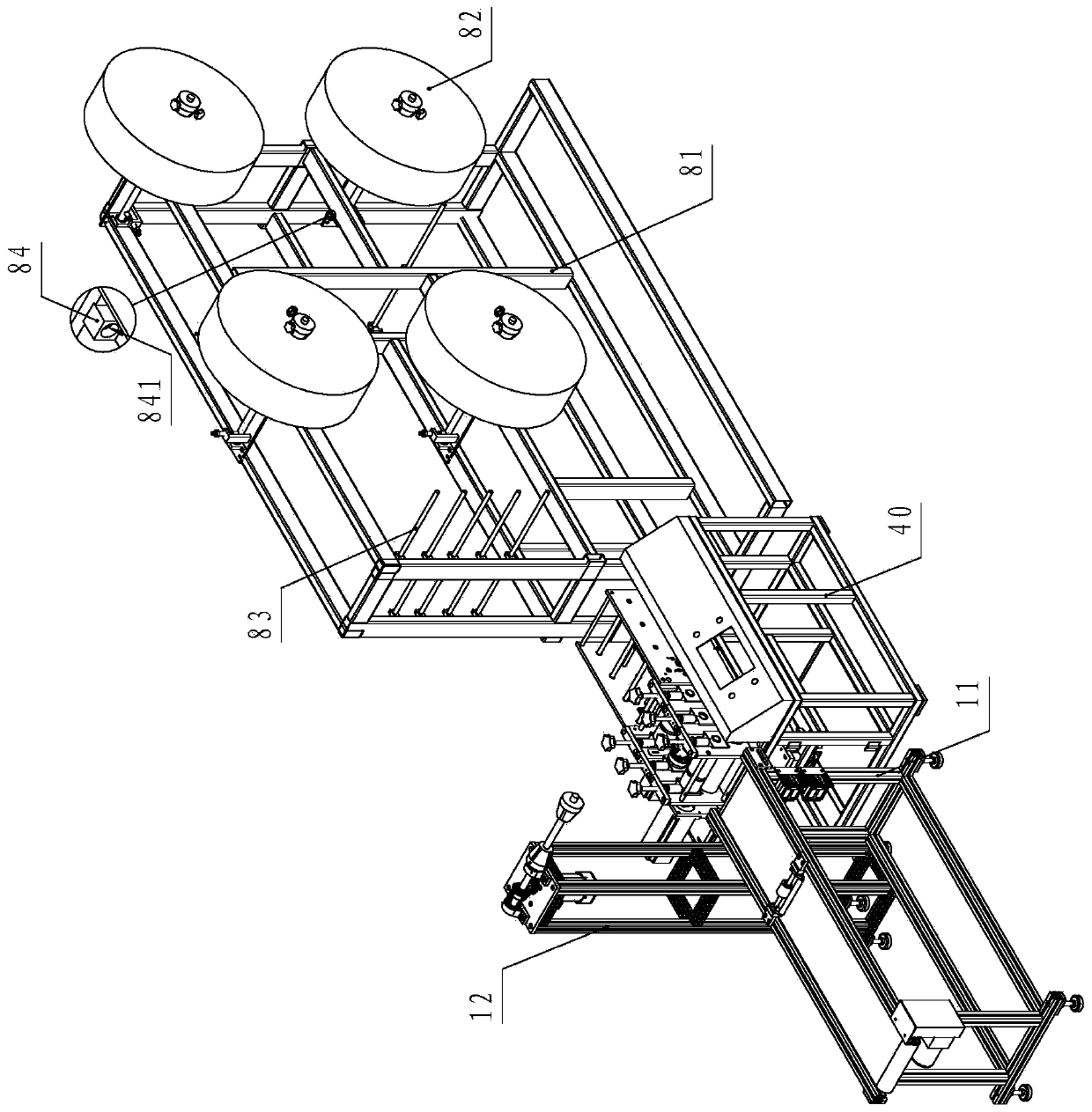

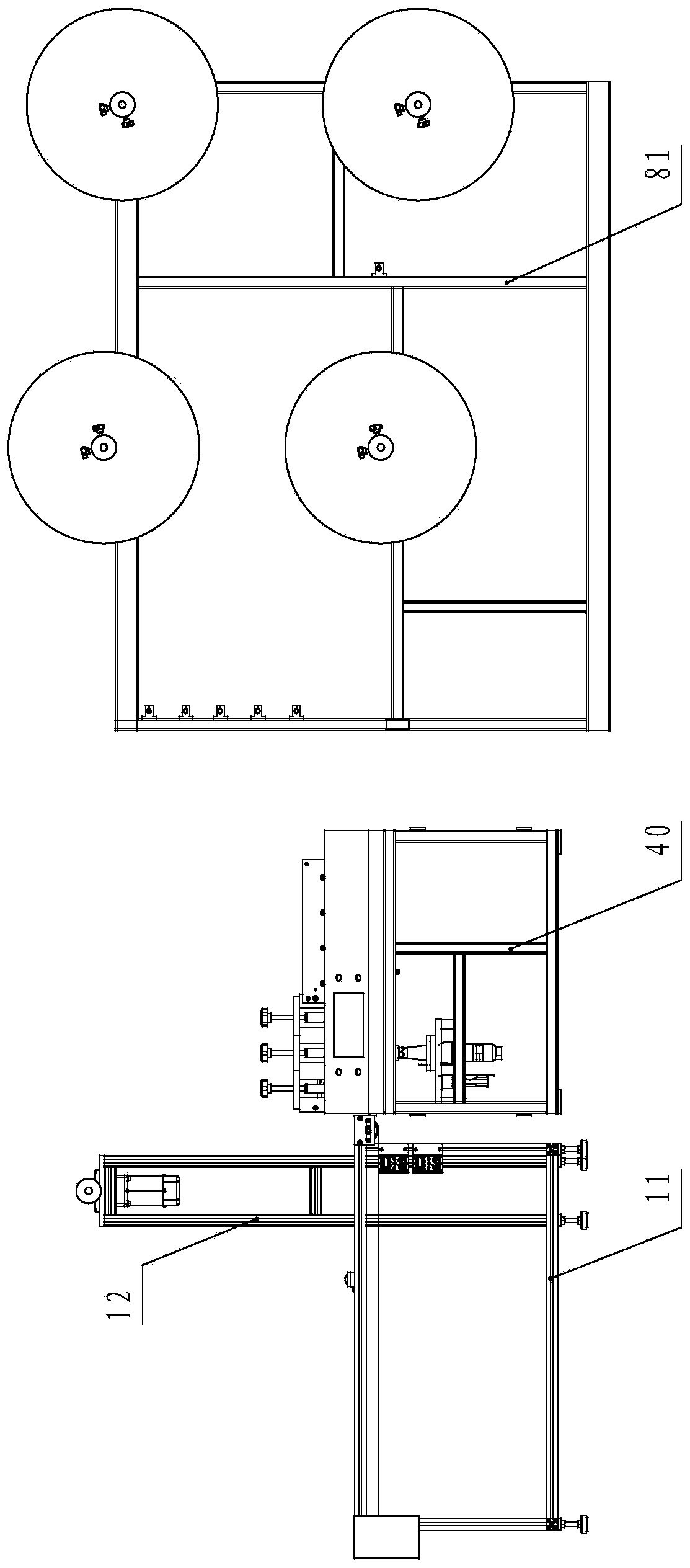

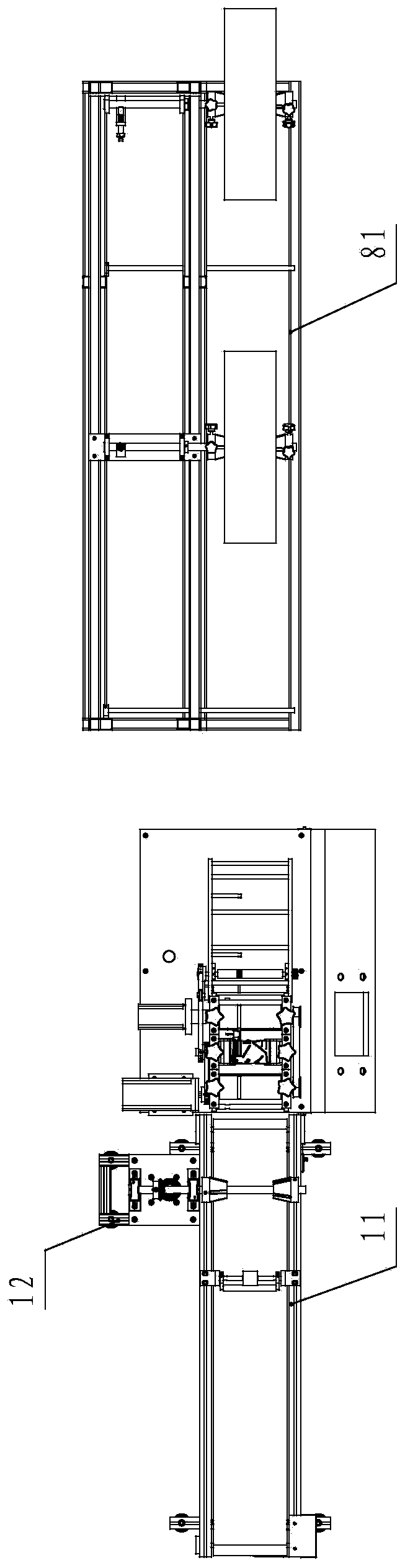

[0026] Such as Figure 1 to Figure 3 As shown, the mask sheet forming machine of the present invention includes: an unwinding device, a forming device and a stripping device placed in sequence according to the processing order, such as Figure 4 to Figure 5 As shown, the specific structure of the molding device includes: a molding frame 40, the molding frame 40 is provided with an installation base plate 41, a pair of forming station support plates 421 arranged on the installation base plate 41 and a pair of feeding The installation bracket formed by the station support plate 422, a pair of forming station support plates 421 of the installation bracket are respectively provided with a feeding device before forming, a forming roller 65 and a material pulling device after forming through corresponding up and down position adjustment mechanisms. A feeding device is arranged between a pair of feeding station support plates 422 of the bracket, and an ultrasonic device 66 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com