Automatic packing machine

A cartoning machine and automatic technology, applied in the direction of packaging, etc., can solve the problem of low packing efficiency and achieve the effect of improving packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

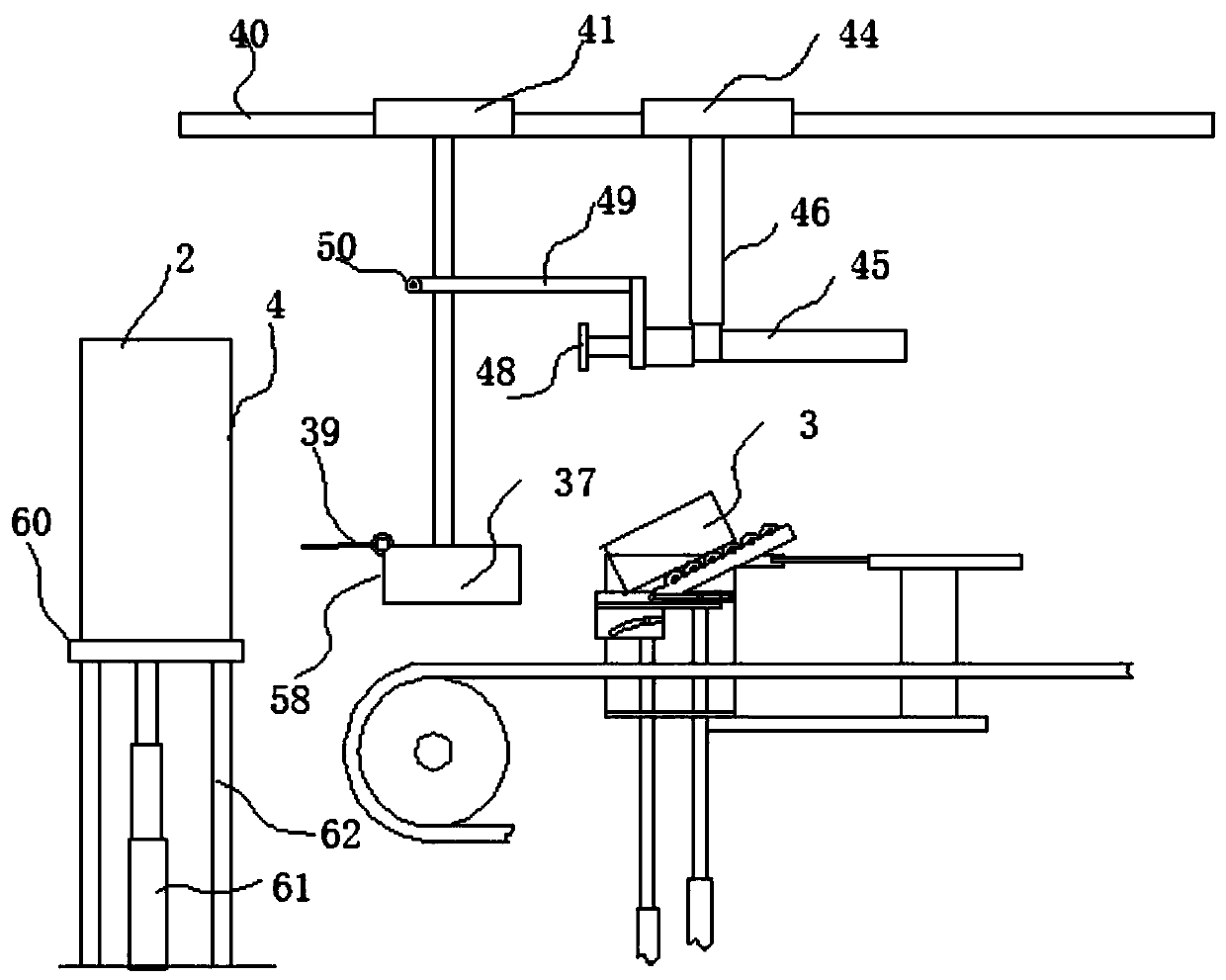

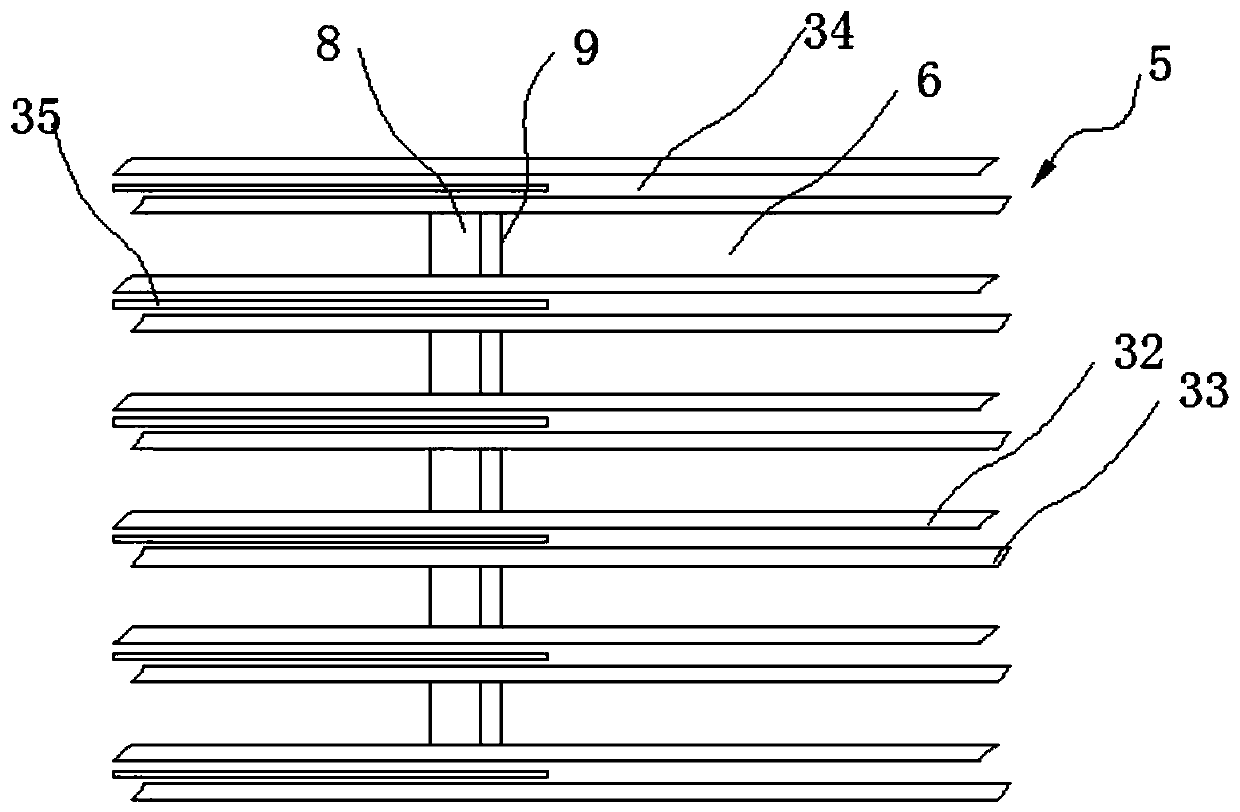

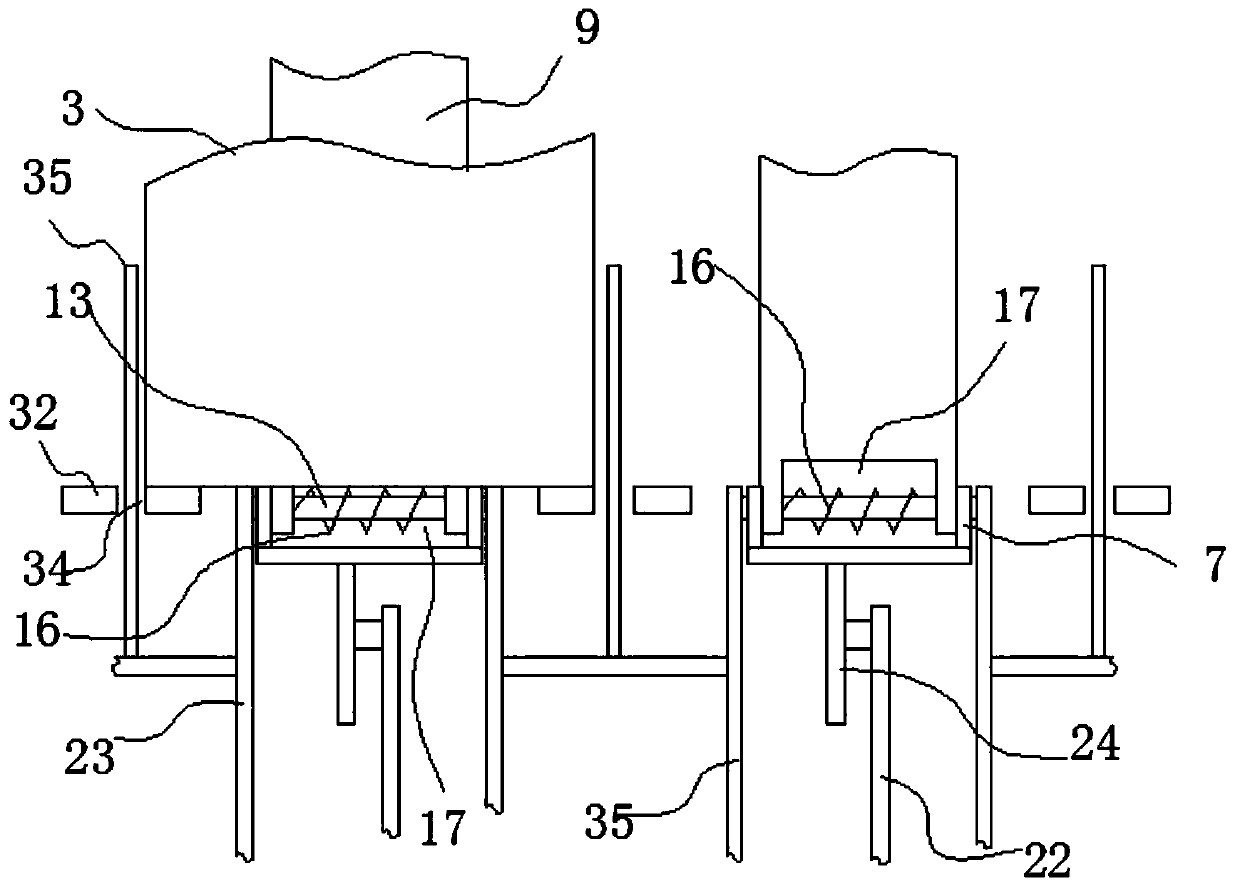

[0026] Such as Figure 1 to Figure 3 As shown, an automatic box packing machine includes a frame 1, the frame 1 is provided with a lifting mechanism, a cargo box 2 is placed on the lifting mechanism, and a horizontally extending conveying mechanism is installed on the frame 1 , the upper opening of the cargo box 2 faces the end of the conveying mechanism, the conveying mechanism is placed with goods 3, and the frame 1 is also provided with an overturning mechanism for turning over the goods 3 conveyed on the conveying mechanism, The overturning mechanism overturns the goods whose height direction is perpendicular to the horizontal direction so that the angle between them and the horizontal direction is less than 60 degrees, and the frame 1 is also provided with a pushing mechanism for pushing the overturned goods into the container. The upper opening of the container faces the end of the conveying mechanism, and the pushing mechanism pushes the overturned goods into the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com