Automatic boxing production line for large bottles and cans

An automatic boxing and packaging production line technology, applied in the direction of automatic packaging control, packaging, packaging bottles, etc., can solve the problems of low efficiency and laborious efficiency, and achieve the effect of improving boxing efficiency and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

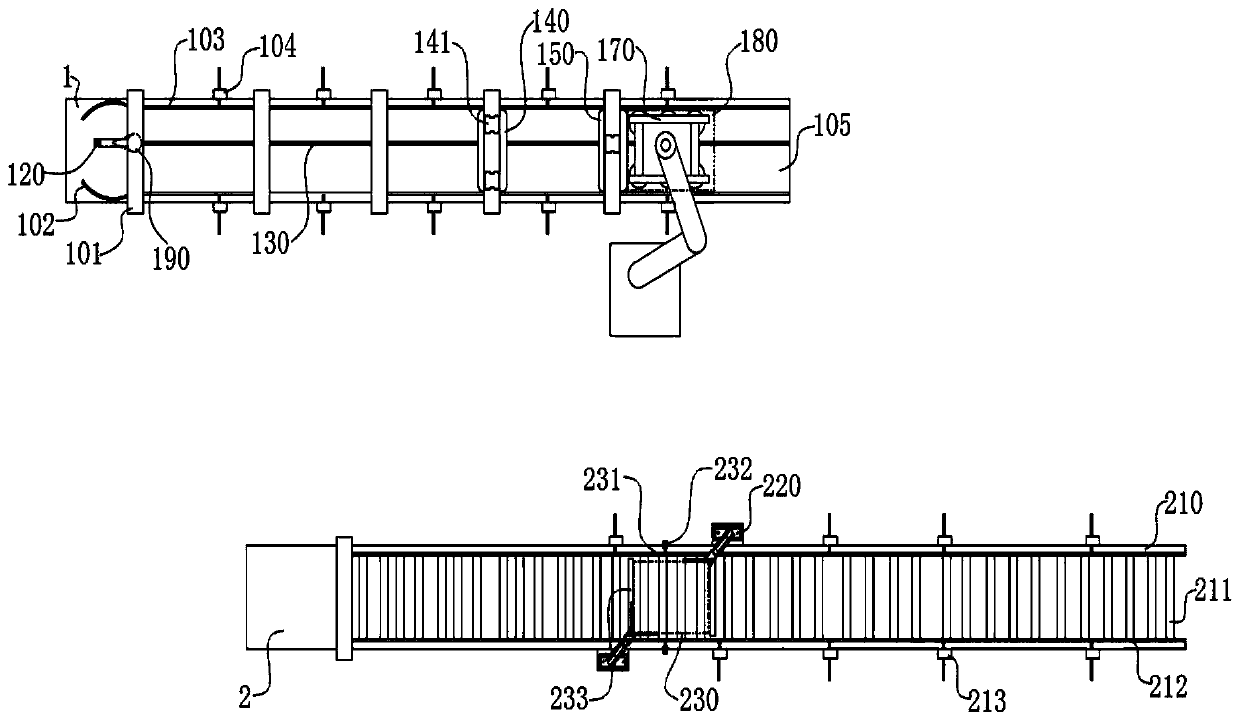

[0039] see Figure 1-6 , is a schematic diagram of the overall structure in an embodiment; including:

[0040] Allocation line 1;

[0041] Sealing production line 2;

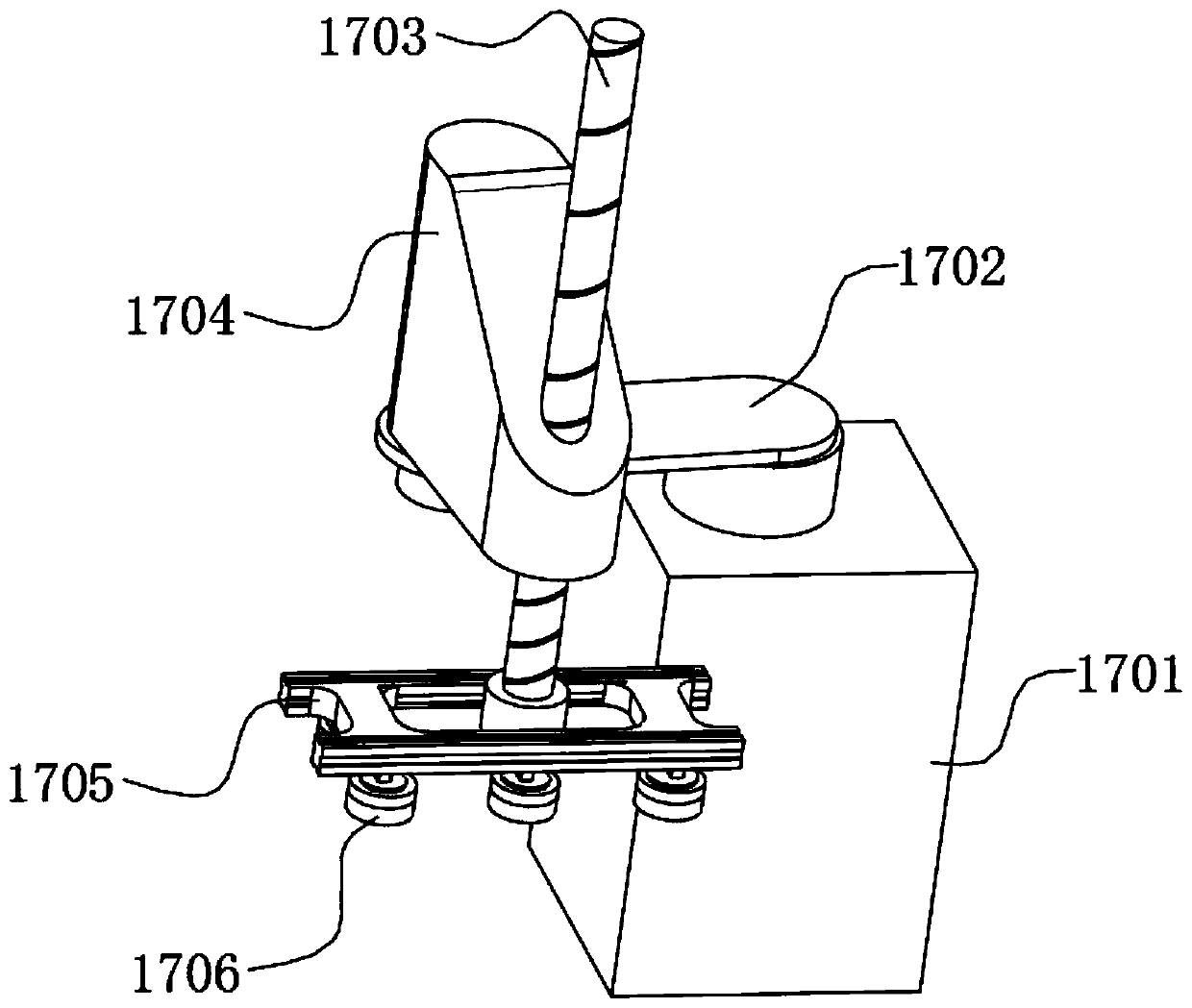

[0042] Manipulator 170;

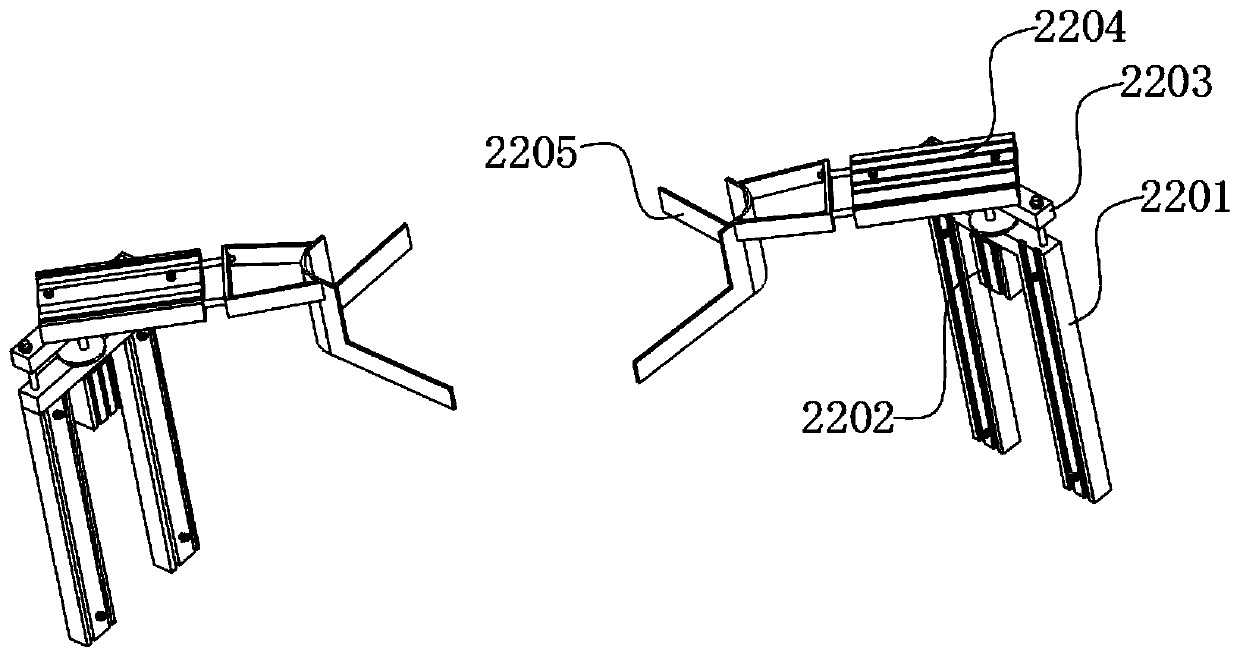

[0043] There are two unpacking devices 220; there are two unpacking devices 220;

[0044] Among them, the bottom of the distribution production line 1 is conveyed by the conveyor belt 105, the bottom of the sealing production line 2 is conveyed by the conveying roller 211, the bottle is conveyed more smoothly by the conveyor belt 105, and the carton is conveyed by the conveying roller 211. In the previous process of the production line 2, the distribution production line 1 transports the cans via the conveyor belt 105 to the grabbing station 180 of the manipulator 170. The grabbing station 180 is an electronic area set by the manipulator and can be adjusted according to the work content.

[0045] The feeding end of the sealing production line 2 is put into packaging cartons, and the...

Embodiment 2

[0055] see figure 1 , is a schematic diagram of the overall structure in an embodiment; including:

[0056] Allocation line 1;

[0057] Sealing production line 2;

[0058] Manipulator 170;

[0059] There are two unpacking devices 220; there are two unpacking devices 220;

[0060] Among them, the bottom of the distribution production line 1 is conveyed by the conveyor belt 105, the bottom of the sealing production line 2 is conveyed by the conveying roller 211, the bottle is conveyed more smoothly by the conveyor belt 105, and the carton is conveyed by the conveying roller 211. In the previous process of the production line 2, the distribution production line 1 transports the cans via the conveyor belt 105 to the grabbing station 180 of the manipulator 170. The grabbing station 180 is an electronic area set by the manipulator and can be adjusted according to the work content.

[0061] The feeding end of the sealing production line 2 is put into packing cartons, and the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com