Tiltable material pouring three-dimensional compost fermentation frame and operation method thereof

A fermentation rack and three-dimensional technology, which is applied in the field of three-dimensional composting fermentation racks that can be tilted and poured, can solve the problems of occupying agricultural land and compost fermentation occupying a large area, and achieve the effect of solving a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

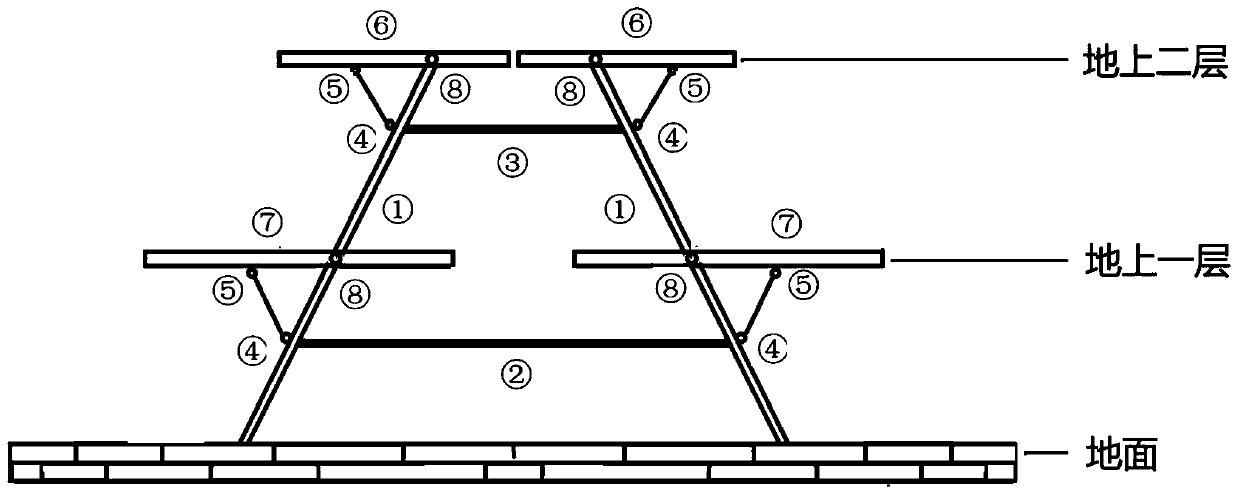

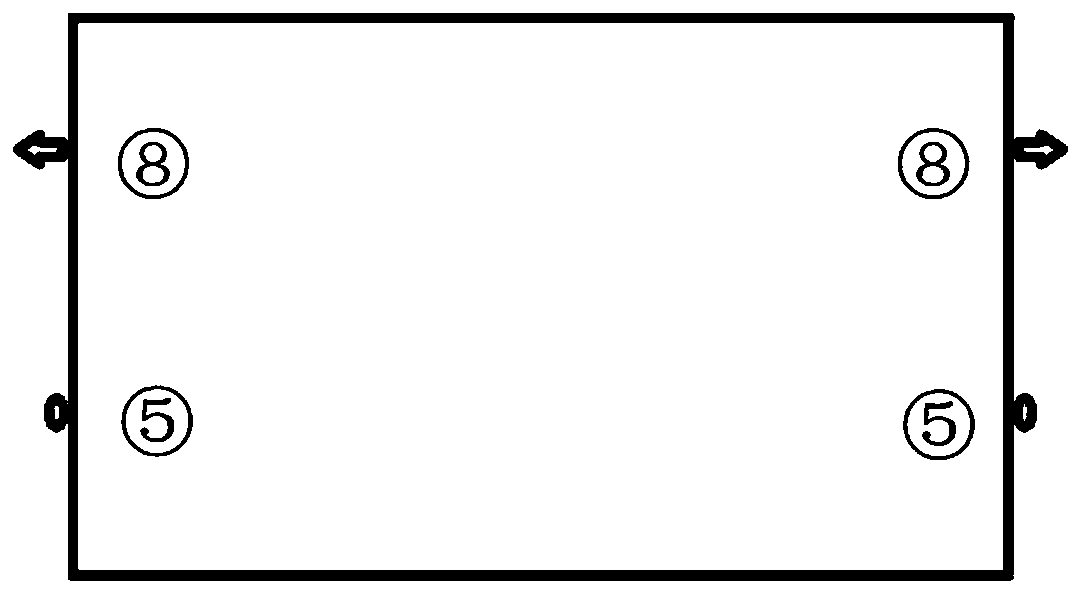

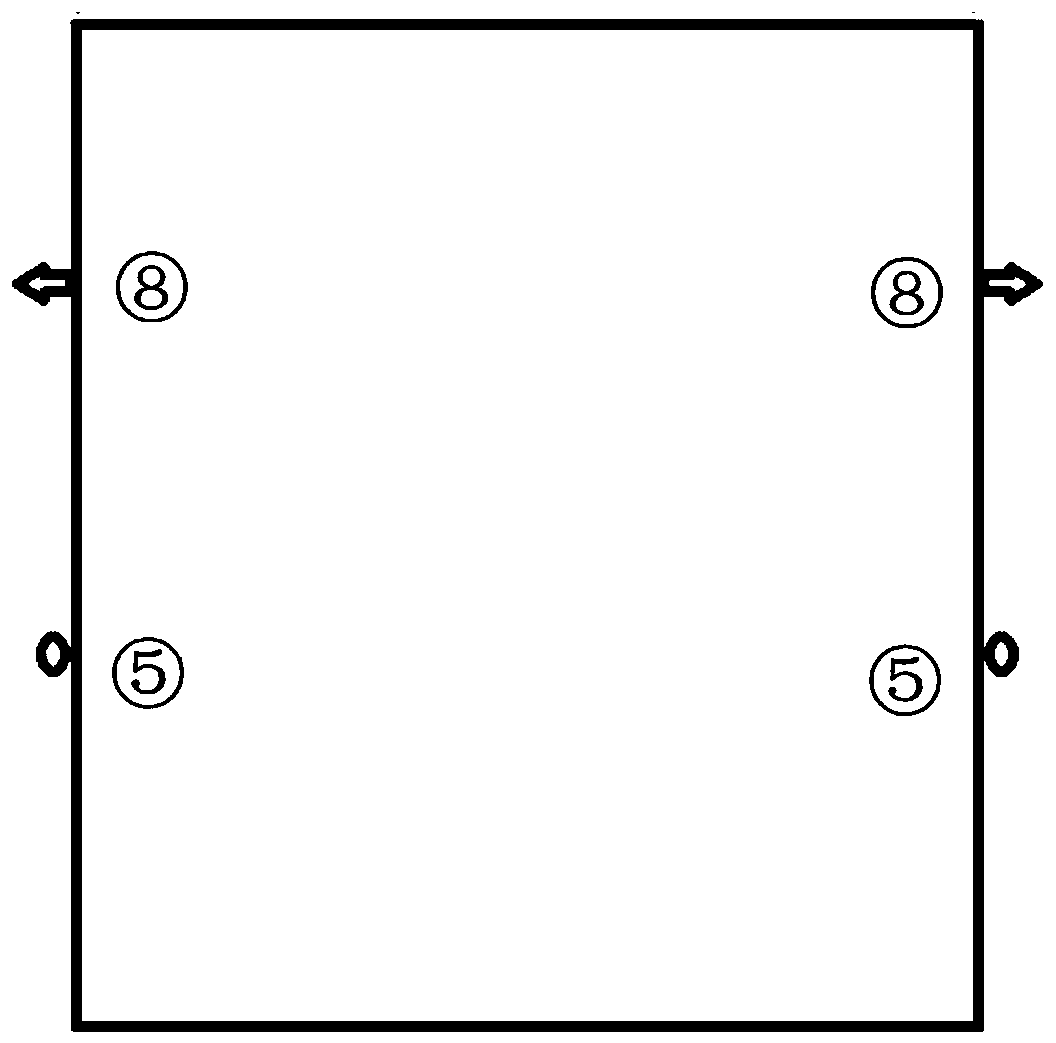

[0021] refer to figure 1 , a three-dimensional composting fermentation rack that can be tilted and dumped, including a main frame, a dung-bearing board, and an unlockable bracket. The main frame is composed of a slanted angle steel column 1, a bottom horizontal bracket 2 and an upper horizontal bracket 3. One end of the unlockable bracket is fixed on the column 1 through the rotatable fixed terminal 4 of the bracket, and the other end is a shackle through the hook ring. The fixed terminal 5 is connected to the manure-bearing board to play a supporting and fixing role; the manure-bearing area is divided into three layers: the manure-bearing area on the ground, the manure-bearing area on the first floor and the manure-bearing area on the second floor above the ground, and the manure-bearing area on the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com