Method for spreading high-temperature steamed food grains for brewing on ground

A ground and grain technology, applied in the field of winemaking, can solve the problems of reducing the appropriate temperature time for grain cooling, low work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

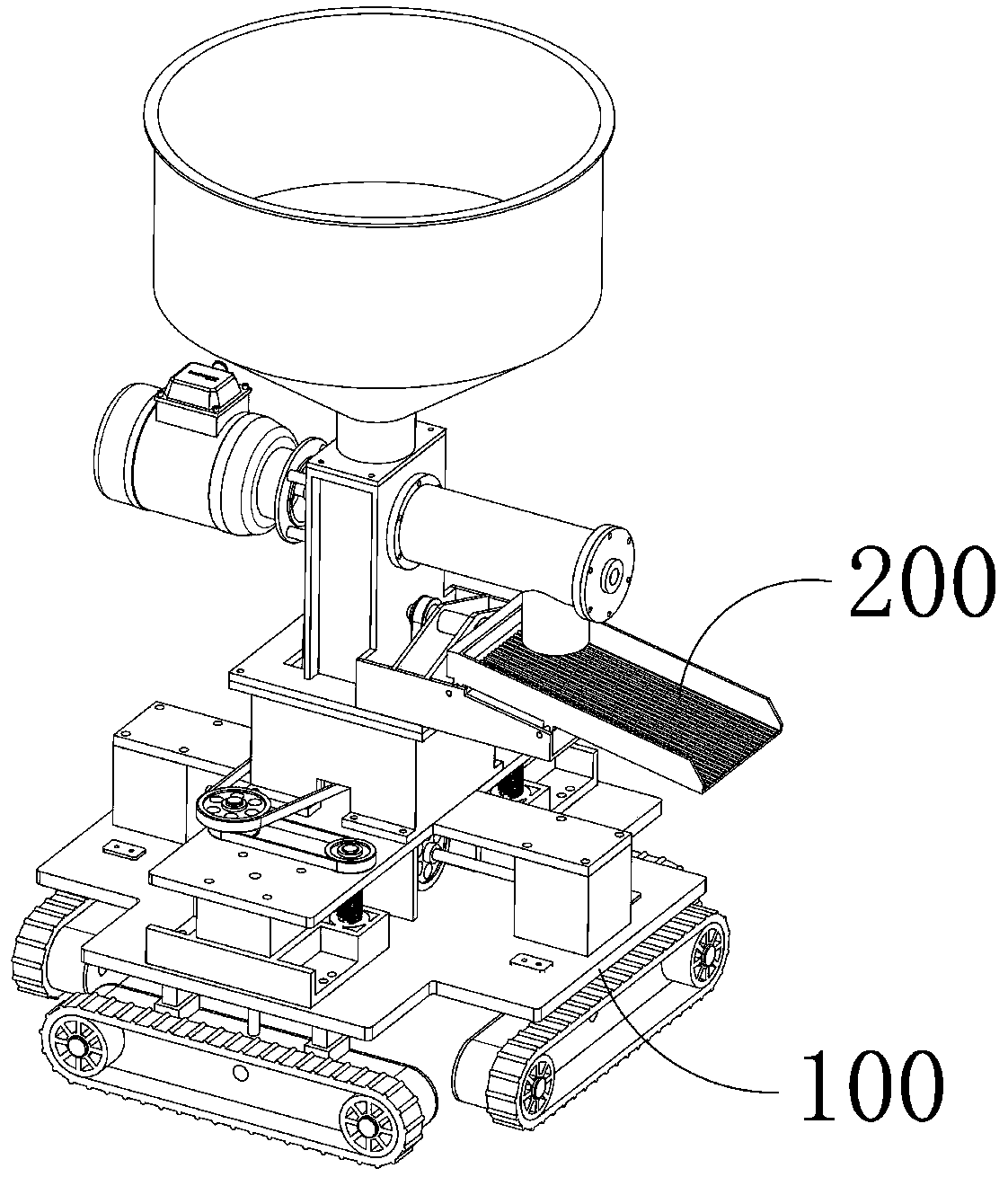

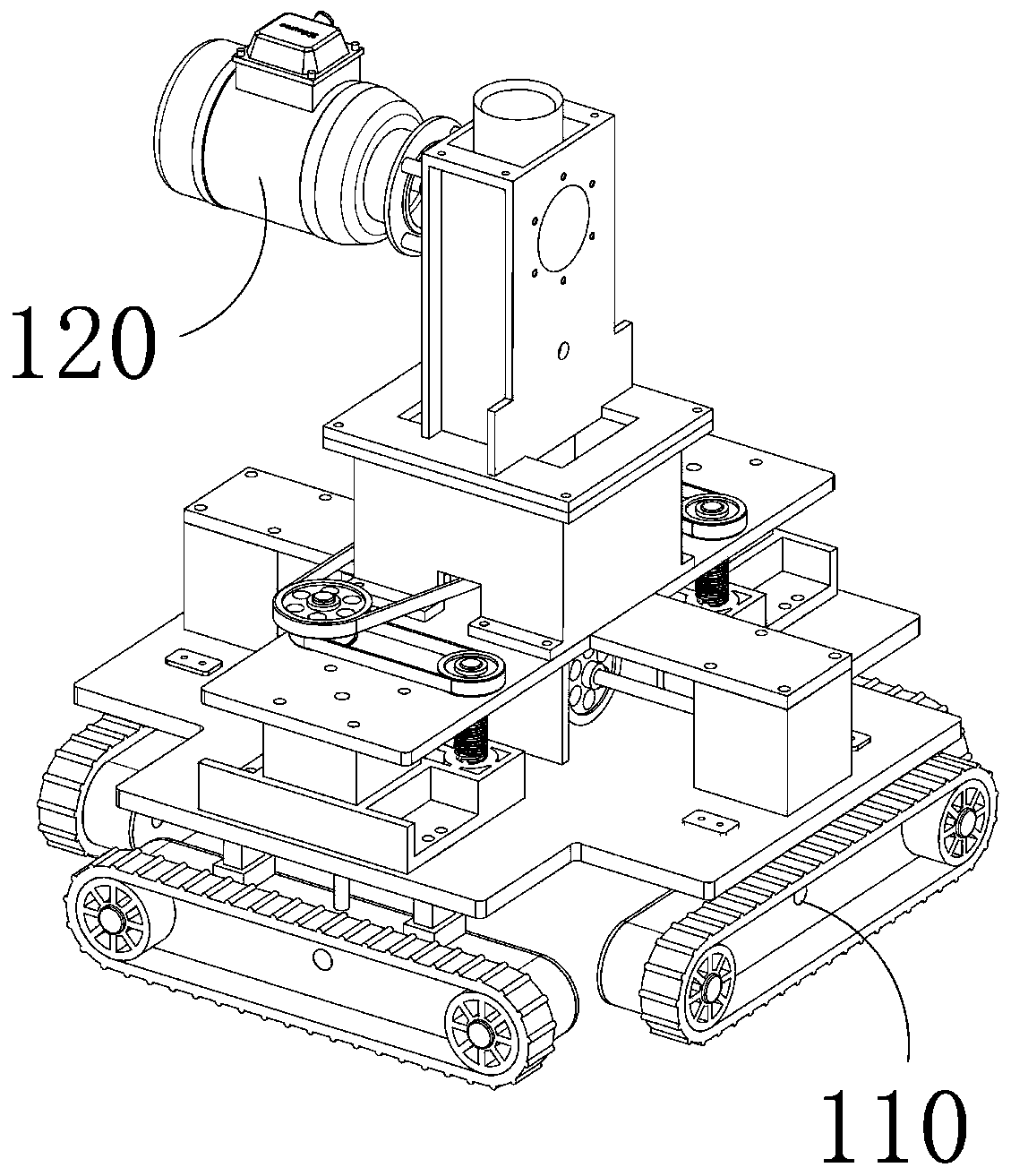

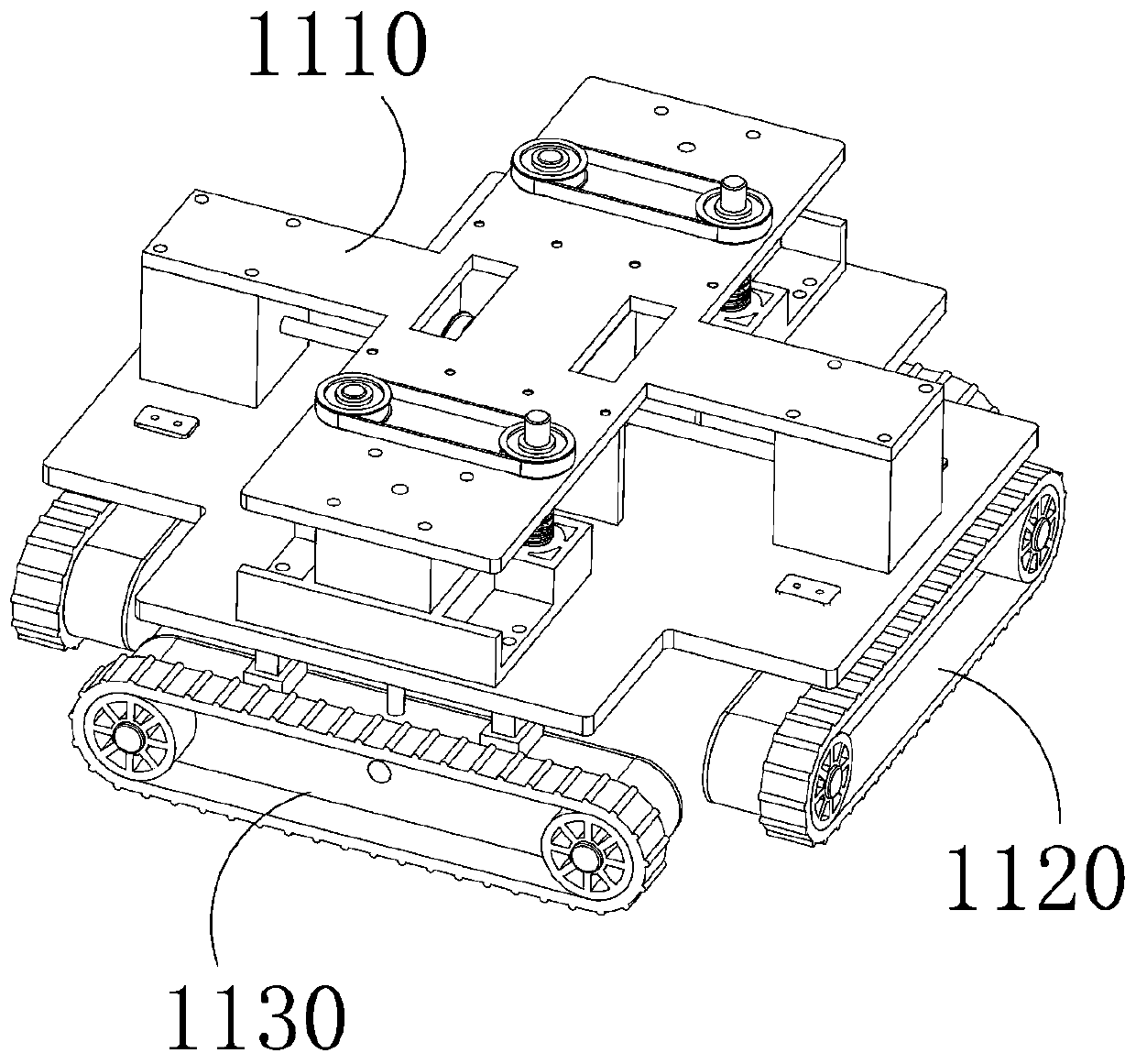

[0082] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0083] The present invention has the advantage of cooling the high-temperature steamed wine-making grains in that it only needs to dump and store the high-temperature-steamed wine-making grains into the storage shell, and the subsequent process of evenly guiding the grains to the ground can be carried out by driving The combination of the device and the guiding cooling device is realized, in which the staff only need to operate remotely through the controller indoors or in a cool place, which greatly reduces the labor intensity of the staff and improves work efficiency; since there is no need for staff to manually transfer the grain spread to the ground, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com