Method for opening path for antimony in tin smelting by combining pyrogenic process with wet process

A wet process and pyrotechnic technology, applied in the field of tin smelting, can solve the problems that tin smelters cannot recover tin and antimony economically and efficiently, the amount of anode slime is too large, and the economy is not ideal, so as to reduce the amount of recycling treatment, increase the Large processing capacity, realize the effect of cost-effective open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

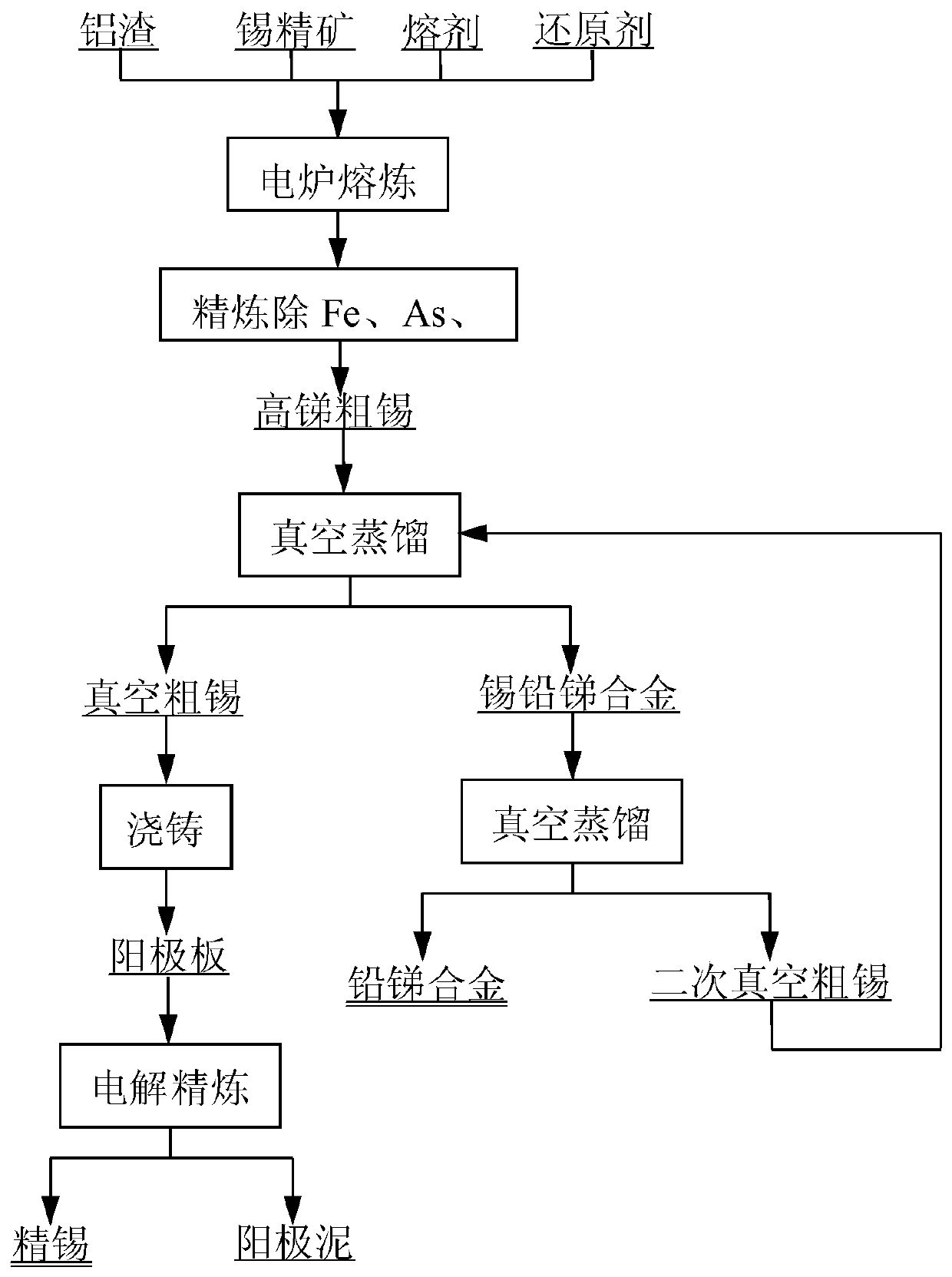

[0023] A method of combining pyrotechnics and wet processes to open the circuit of antimony in tin smelting, according to figure 1 The process flow shown is for processing 100t of high-antimony crude tin. The high-antimony crude tin is produced by refining crude tin and adding aluminum to remove arsenic and antimony. Tin, and then pre-removed high-antimony crude tin after removing the three impurities of iron, arsenic and copper (during this process, the mixed bismuth and arsenic can also be removed to meet the requirements of refined tin products). During the smelting process, solvents and reducing agents are normally used, and concentrates are used to adjust the furnace grade. Aluminum slag is the refining slag of adding aluminum to remove arsenic and antimony in tin smelting, which is a conventional and mature process. The composition of pre-dedoped high antimony crude tin is Sn 83.59wt.%, Sb 6.54wt.%, Pb 8.95wt.%, As 0.16wt.%, Bi0.28wt.%, and the rest are impurities. Spe...

Embodiment 2

[0028] according to figure 1The process flow shown is for processing 100t of high-antimony crude tin. The high-antimony crude tin is produced by refining crude tin and adding aluminum to remove arsenic and antimony. Tin, and then pre-removed high-antimony coarse tin with three impurities of iron, arsenic and copper removed, its composition is Sn 83.87wt.%, Sb 7.69wt.%, Pb 6.26wt.%, As0.21wt.%, Bi 1.41wt.%, the rest are impurities. Specific steps are as follows:

[0029] (1) Melt high-antimony crude tin at a temperature of 450-550°C, then continuously and evenly add it to a vacuum furnace with a maximum processing capacity of 20t / d, control the processing capacity to 16t / d, and control the distillation temperature at 1200-1250 ℃, the vacuum degree in the furnace is controlled at 2-6Pa. The obtained composition is Sn 97.34wt.%, Sb 1.7wt.%, Pb 0.12wt.%, As 0.025wt.%, Bi0.024wt.%, the remainder is impurity vacuum crude tin 77.20t, and enters the condenser to separate The compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com