Preparation method of covering agent of alkaline steel ladle or tundish

A production method and technology of covering agent, which are applied in the production field of basic ladle or medium-ladle covering agent, can solve the problems of low utilization rate and high energy consumption of calcium-silicon slag, and achieve the reduction of circulating treatment volume, price reduction and simple process method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Flash-evaporate and dry the dehydrated calcium-silicon slag at 100-120°C to remove the powdery material obtained by removing the attached water;

[0015] The powdery material after flash evaporation enters the calcining furnace with a combustion temperature of 800℃~1200℃. After the calcined product is cooled, it is ground into powder with a particle size ≤0.088mm for use; it can be ground by a ball mill. The combustion temperature can be any temperature value between 800°C and 1200°C, such as 800°C, 850°C, 900°C, 1000°C, 1100°C or 1200°C, which can remove the crystal water in the calcium silicon slag or realize calcium The crystal phase transformation of the substance in the silicon slag.

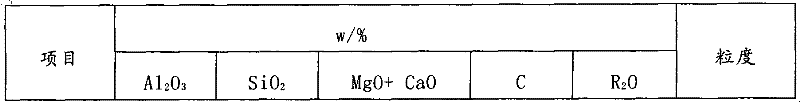

[0016] The chemical composition is shown in the table below.

[0017] name

CaO

Al 2 O 3

SiO 2

Fe 2 O 3

TiO 2

R 2 O

Burn

%

35-48

32-42

<3.5

<1.5

<0.02

5-10

<8

[0018] The silica and lime are mixed uniformly according to the weight ratio of 45:55, and the me...

Embodiment 2

[0023] Flash-evaporate and dry the dehydrated calcium-silicon slag at 100-120°C to remove the powdery material obtained by removing the attached water;

[0024] The powdery material after flash evaporation enters the calcining furnace with a combustion temperature of 1100℃. After the calcined product is cooled, it is ground into powder with a particle size of ≤0.088mm for use; it can be ground by a ball mill.

[0025] The chemical composition is shown in the table below.

[0026] name

CaO

Al 2 O 3

SiO 2

Fe 2 O 3

TiO 2

R 2 O

Burn

%

35-48

32-42

<3.5

<1.5

<0.02

5-10

<8

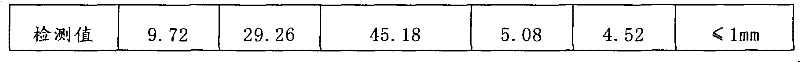

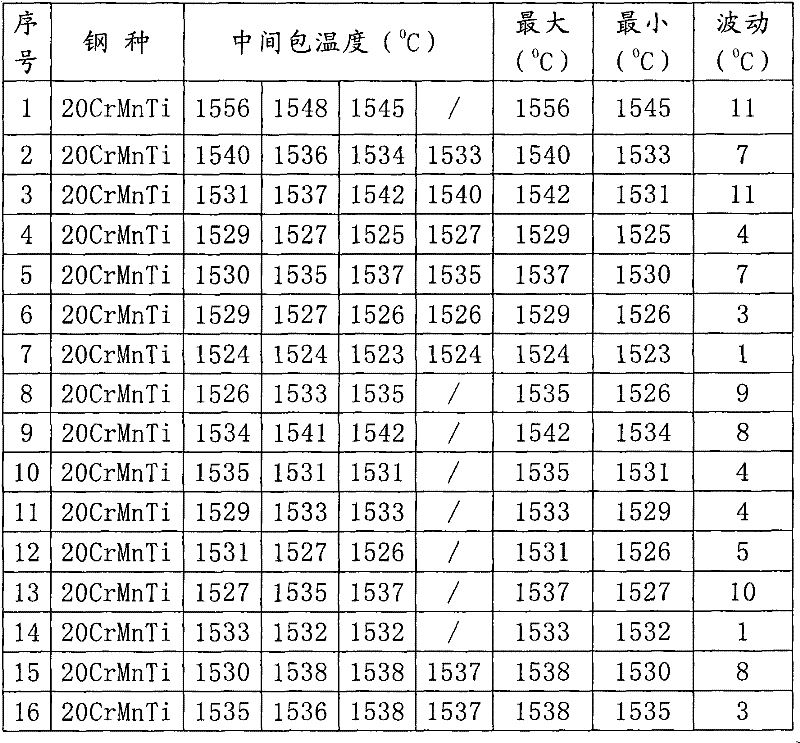

[0027] The silica and lime are mixed uniformly according to the weight ratio of 45:55, and the melting is carried out. The melting conditions are: heating up to 1350℃~1550℃, after 8-12 hours, it will form the main lithofacies as CaO·SiO 2 的melt. After the melt is crushed, 0-30% fixed carbon is added according to the different steel types for co-grinding to a material degree ≤ 1mm. After crushing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com