Pavement repairing device for highway engineering

A road surface repair and engineering technology, applied in road repair, roads, roads, etc., can solve the problems of labor and time-consuming, labor-intensive and time-consuming, and the inability to use large mixers and pavers, etc., to improve battery life, The effect of saving labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

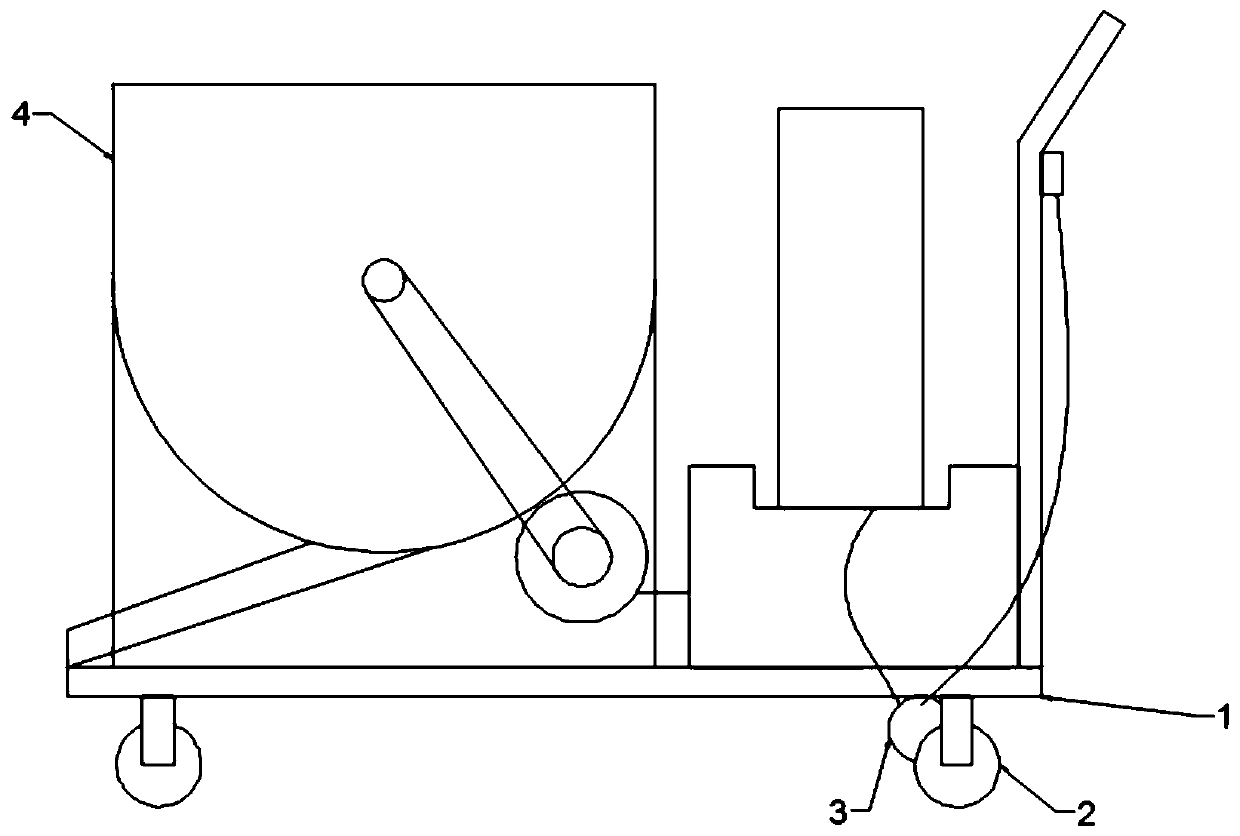

[0043] A road surface repair device for highway engineering of the present invention comprises a base plate 1, four directional pulleys 2 and a drive motor 3 are fixedly connected to the bottom of the base plate 1; the four directional pulleys 2 are facing in the same direction; bottom corners;

[0044] The driving motor 3 is fixedly connected between the two directional pulleys 2 at one end of the bottom of the base plate 1; the driving motor 3 is connected to the directional pulley 2 under control;

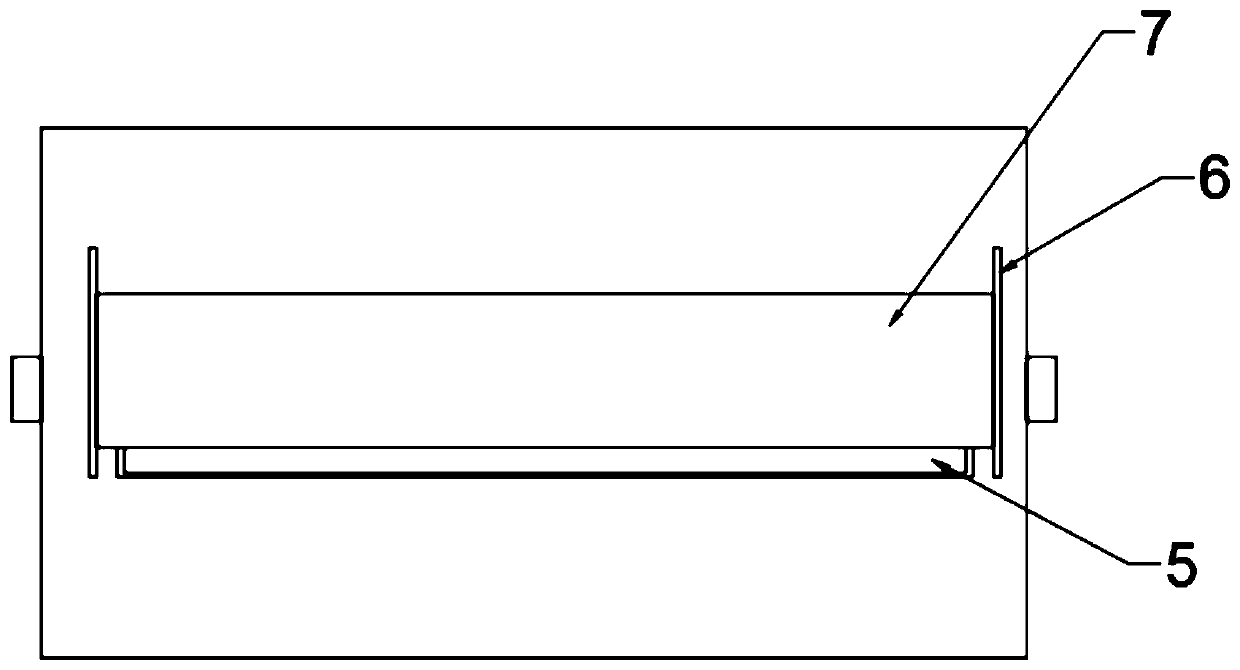

[0045] The mixer 4 is fixedly connected to one end of the upper part of the bottom plate 1; the bottom of the mixer 4 is provided with a material outlet 5 along the length direction of the mixer 4; both sides of the material outlet 5 are vertically fixedly connected with a card slot 6; the upper and lower sides of the two card slots 6 The sliding connection has a baffle plate 7;

[0046]Wherein, base plate 1 can make mixer 4 move more conveniently as the moving carrier of mixer...

Embodiment 2

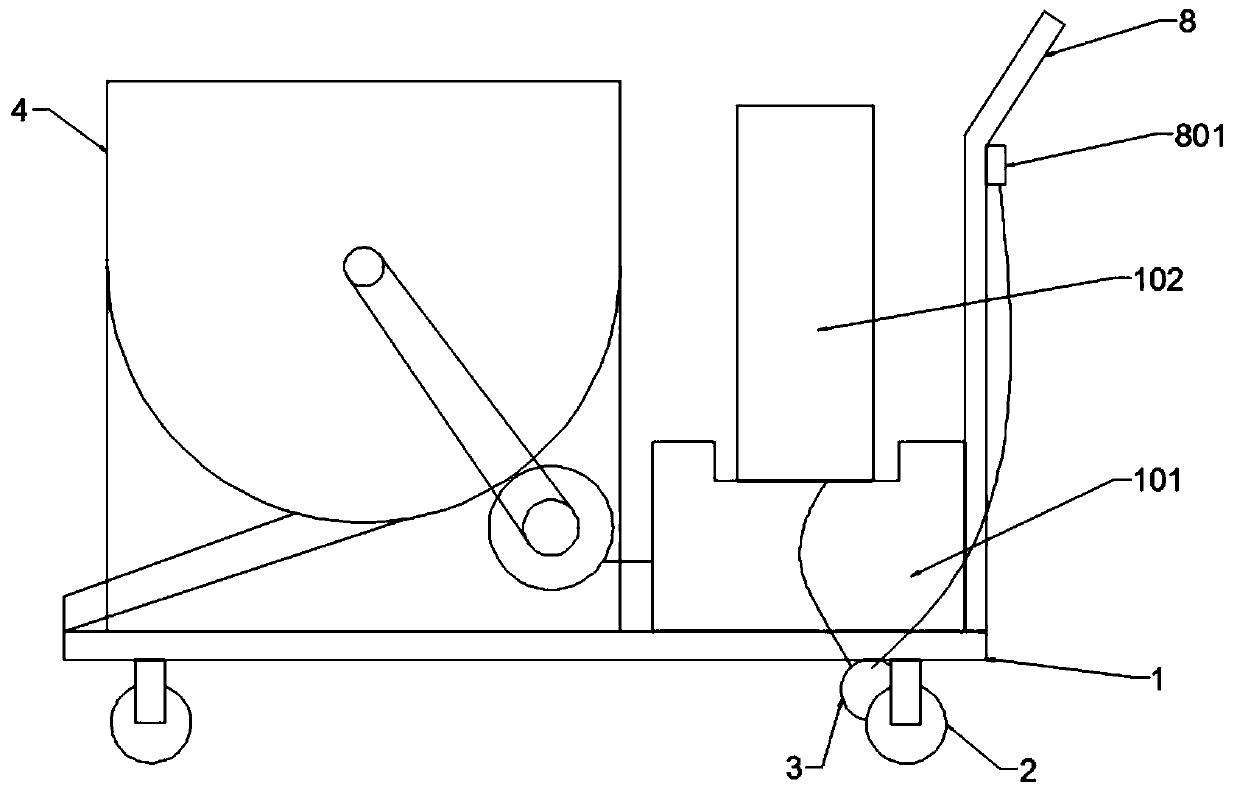

[0050] This embodiment relates to a road surface repair device for highway engineering, which has roughly the same structure as that of Embodiment 1. This embodiment is further optimized on the basis of Embodiment 1: the upper part of the bottom plate 1 is perpendicular to the end away from the mixer 4 and is welded with a handrail 8. The handrail 8 can facilitate the staff to control the direction of the bottom plate 1;

[0051] In order to further optimize a road repair device for road engineering, a speed regulating knob 801 is fixedly connected to the upper part of the handrail 8, and the speed regulating knob 801 is controlled and connected to the drive motor 3 through a circuit, and the drive motor 3 realizes different functions under the control of the speed regulating knob 8. Rotating speed.

[0052] In order to further optimize a road surface repair device for road engineering, a battery base 101 is fixedly connected between the mixer 4 and the handrail 8, and the bat...

Embodiment 3

[0056] This embodiment relates to a road surface repairing device for highway engineering, which has roughly the same structure as that of Embodiment 1. This embodiment is further optimized on the basis of Embodiment 1: the mixer 4 includes a horizontally placed mixing drum 401, a horizontally penetrating The transmission shaft 402 of the mixing drum 401 and the second motor 403 that is rotationally connected with the transmission shaft 402; the transmission shaft 402 is evenly and fixedly connected with the stirring blade 404; the stirring blade 404 is located in the mixing drum 401; the second motor 403 and the transmission shaft 402 Rotate and connect between them by conveyor belt 405;

[0057] Wherein, mixer 4 adopts the horizontally placed mixing drum 401 to make the material outlet 5 at the bottom of the mixing drum 401 longer, and the longer material outlet 5 can expand the coverage area when the repair material is discharged; the second motor 403 drives the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com