Beam and board separating type layering shock isolation structure

A separate, beam-slab technology, used in earthquake-proof, building components, building structures, etc., can solve the problems of small vertical natural vibration period, large vertical rigidity of isolation bearings, and no isolation of vertical earthquakes. Increase the vertical natural vibration period, ensure the integrity and stability, and have the effect of good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objectives and advantages of the present invention clearer, the following further describes the present invention in detail with reference to embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, and do not limit the present invention.

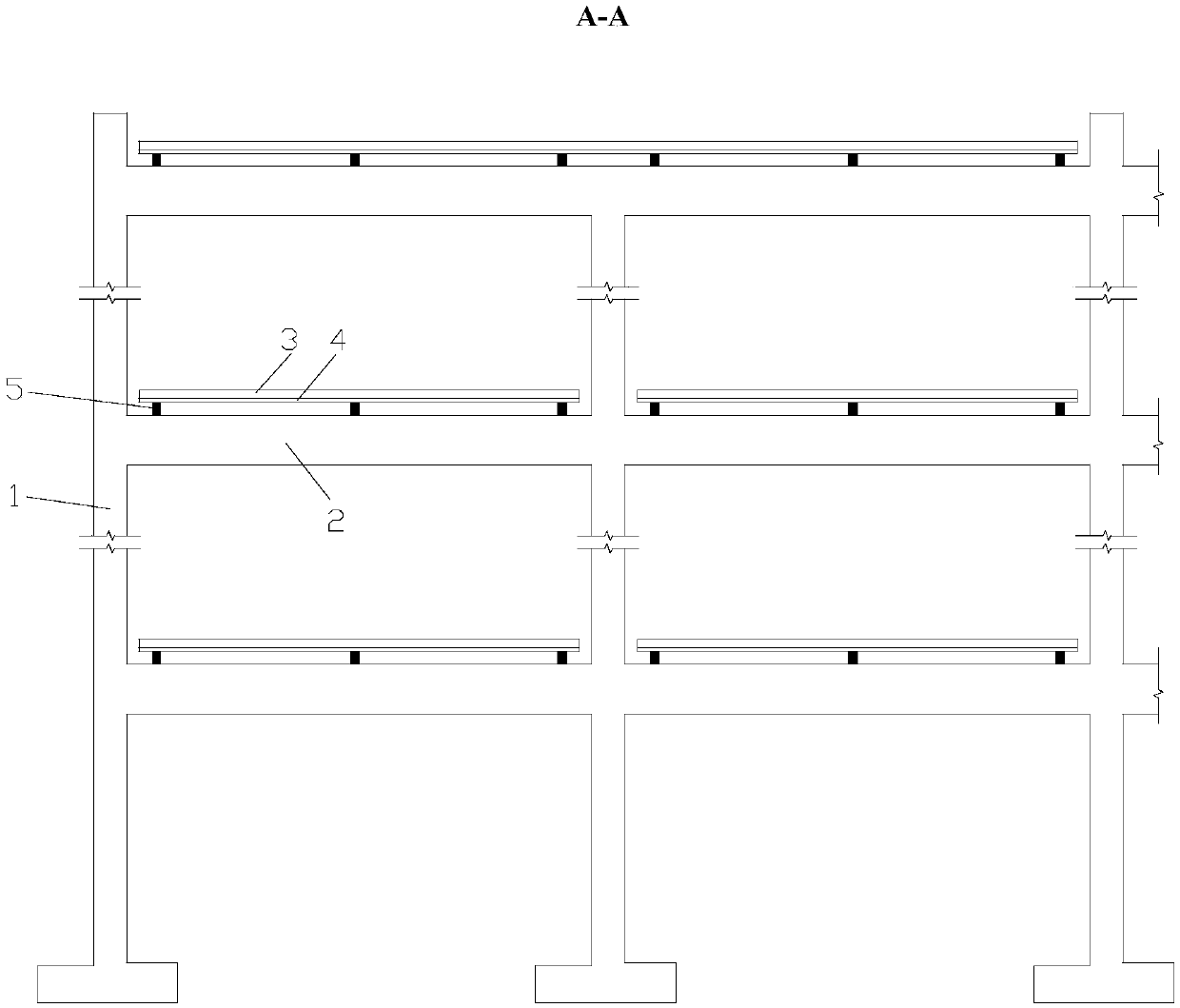

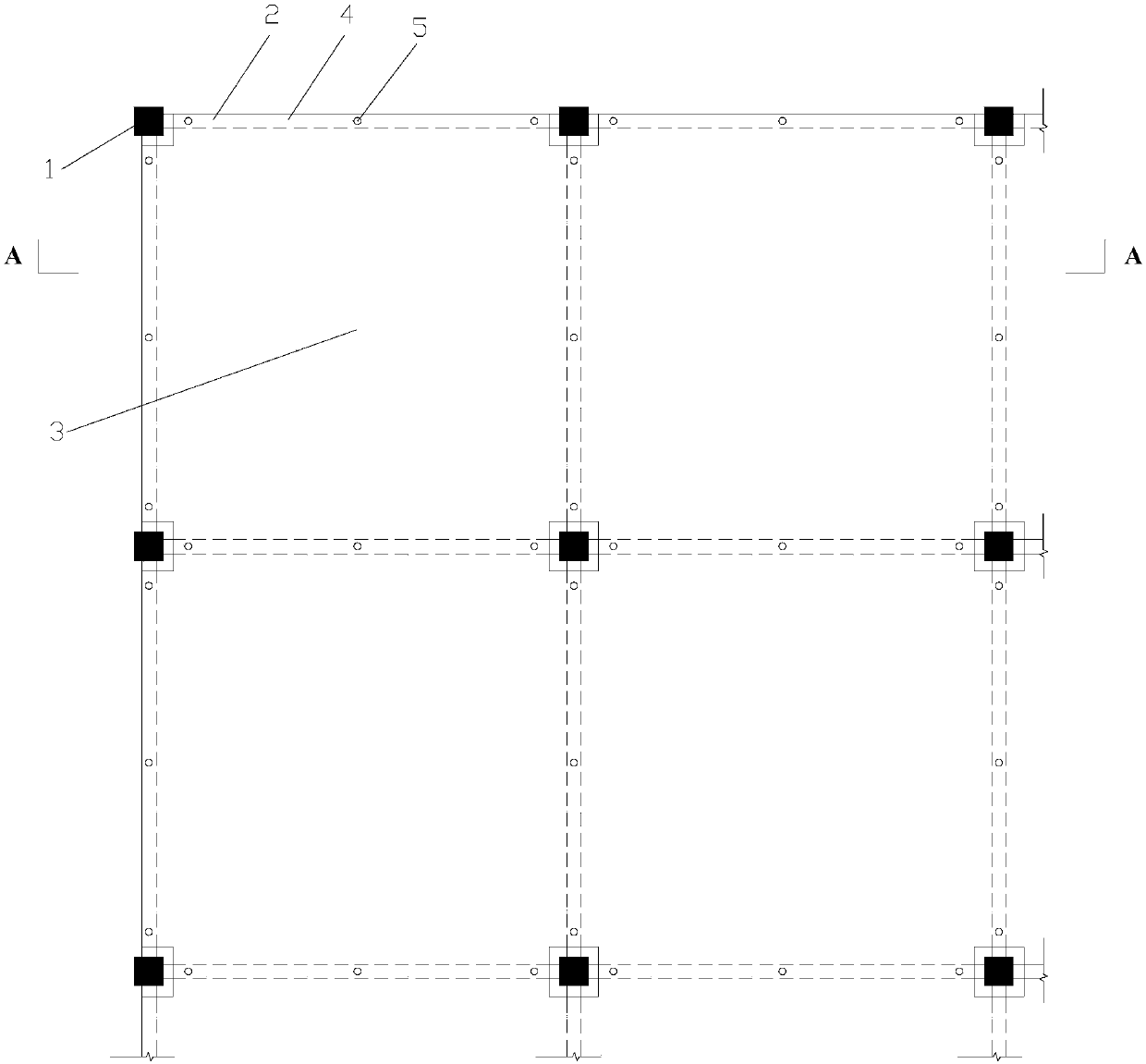

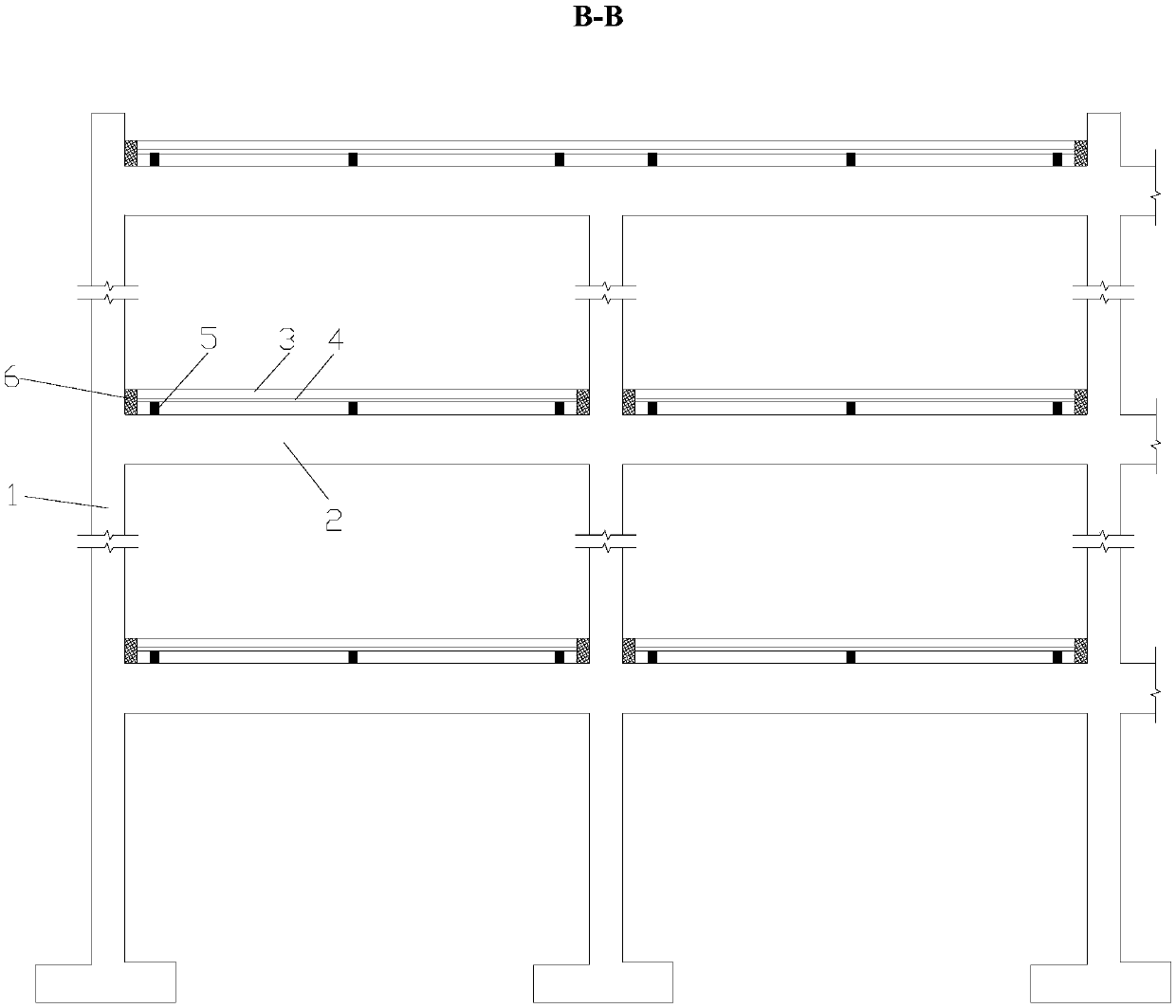

[0039] The example of the present invention provides a beam-slab separated layered seismic isolation structure. A single-story reinforced concrete frame knot, such as Picture 11 As shown, the column section size b×h=400mm×400mm, the beam section size b×h=200mm×600mm, the floor thickness is 150mm, and the floor live load is 2KN / m 2 , Using C30 concrete, elastic modulus E=30×10 6 KN / m 2 , The damping ratio of the structure is 0.05, the fortification intensity is 7 degrees for the class II site, the design basic seismic acceleration is 0.10g, and the design seismic group in the area where the building is located is the second group. Calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com