Lead core laminated rubber support seat capable of bearing tensile force

A technology of laminated rubber bearings and lead cores, which is applied to building components, earthquake resistance, construction, etc., can solve problems such as damage, poor tensile bearing capacity, and damage to seismic isolation layers, so as to ensure safety, facilitate construction, and protect structures safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

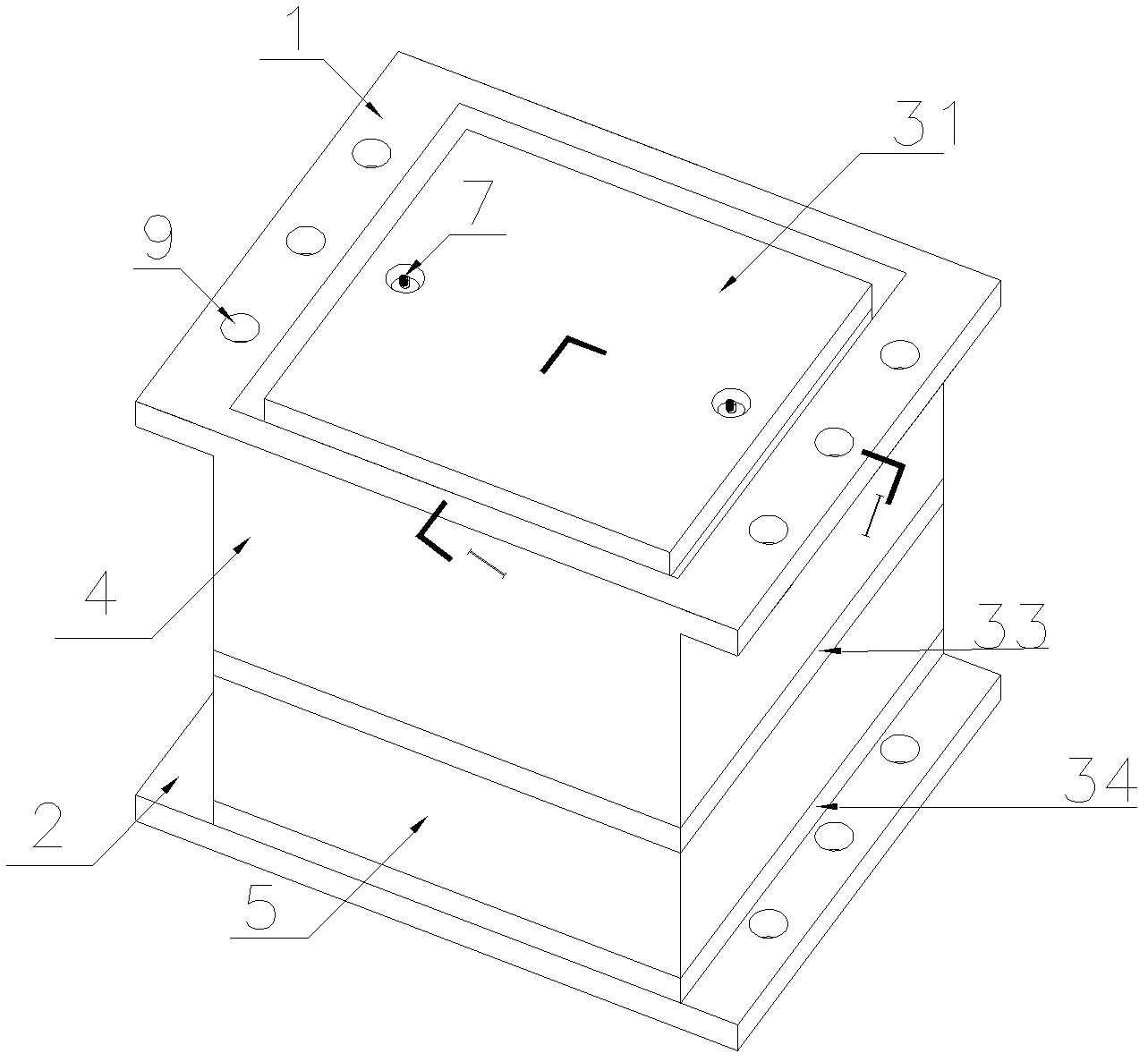

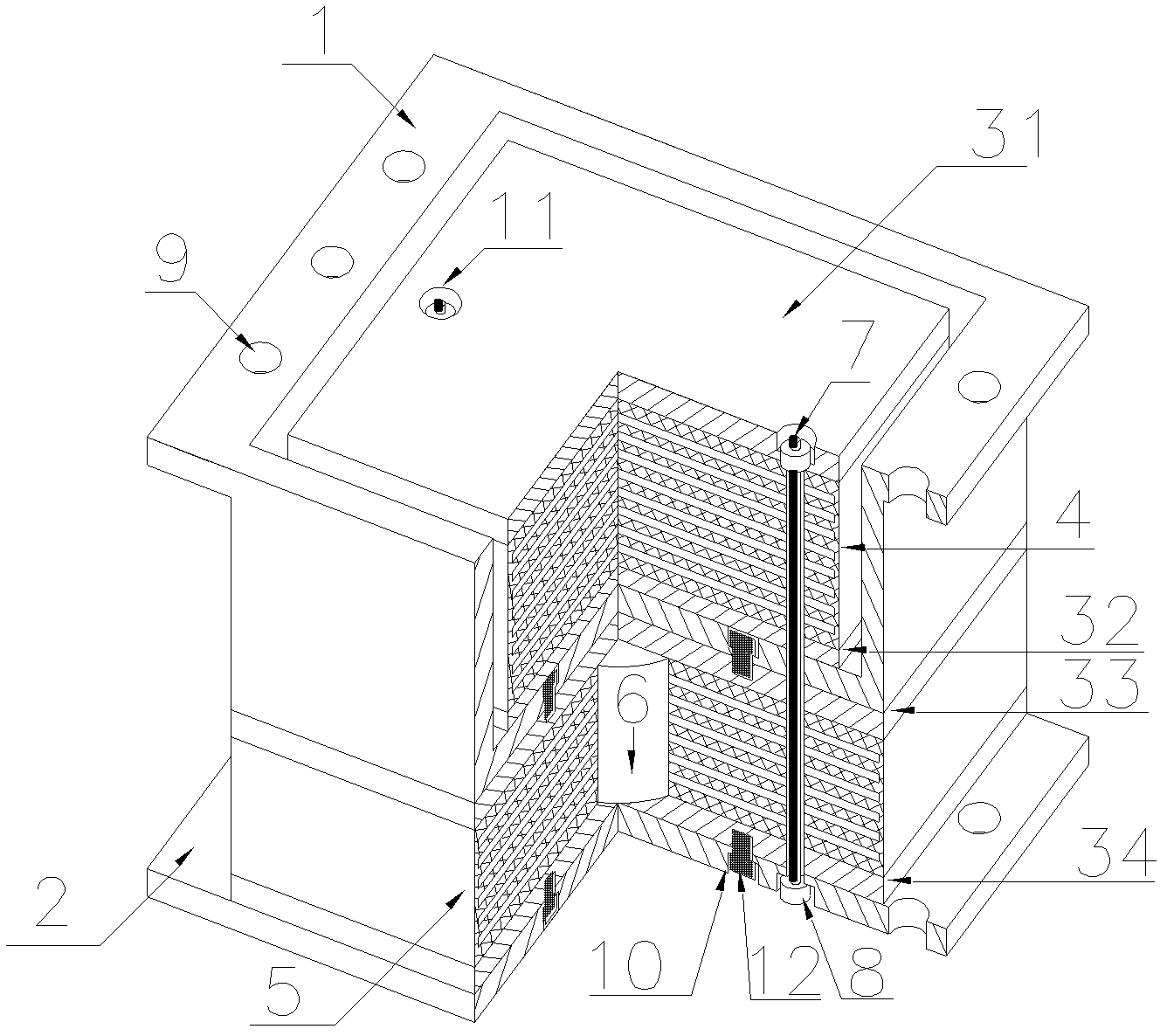

[0034] Such as figure 1 with 2 Shown are the structural diagram and cross-sectional view of Embodiment 1 of the present invention, respectively.

[0035] The laminated rubber bearing is a square bearing. A laminated rubber bearing, comprising an upper connecting piece 1 and a lower connecting plate 2, the upper connecting piece 1 is located above the lower connecting plate 2, the upper connecting piece 1 is provided with a pressure rubber pad 4, the upper connecting piece 1 and the lower connecting plate 2 A shearing rubber cushion 5 is arranged between the lower connecting plates 2 , and the compressed rubber cushion 4 and the shearing rubber cushion 5 are integrally fixed by steel strands 7 .

[0036] The pressure rubber cushion layer 4 is a standard laminated rubber layer.

[0037] An upper sealing plate 31 and a lower sealing plate 32 are respectively bonded to the upper and lower surfaces of the pressure rubber cushion 4 , wherein the lower sealing plate 32 is located ...

Embodiment 2

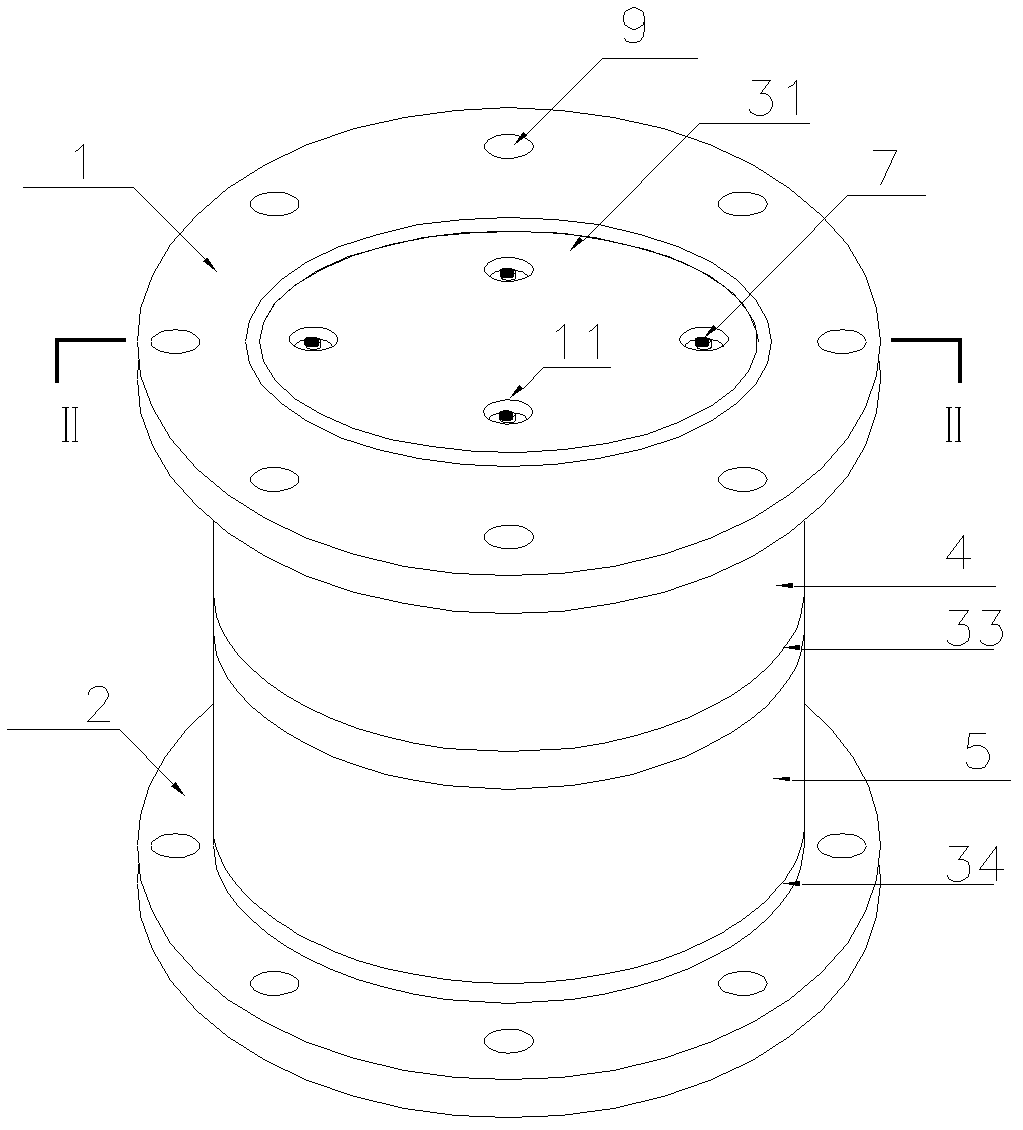

[0047] image 3 with Figure 4 It is the embodiment of the round support in Embodiment 2 of the present invention, and its implementation method is the same as that of the square support in Embodiment 1 above.

[0048] A laminated rubber bearing, comprising an upper connecting piece 1 and a lower connecting plate 2, the upper connecting piece 1 is located above the lower connecting plate 2, the upper connecting piece 1 is provided with a pressure rubber pad 4, the upper connecting piece 1 and the lower connecting plate 2 A shearing rubber cushion 5 is arranged between the lower connecting plates 2 , and the compressed rubber cushion 4 and the shearing rubber cushion 5 are integrally fixed by steel strands 7 .

[0049] The pressure rubber cushion layer 4 is a standard laminated rubber layer.

[0050] An upper sealing plate 31 and a lower sealing plate 32 are respectively bonded to the upper and lower surfaces of the pressure rubber cushion 4 , wherein the lower sealing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com