Mine safety integrated monitoring system

A comprehensive monitoring system and mine technology, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of not being able to notify rescue departments urgently, not being able to give early warnings, and limited monitoring capabilities, to reduce damage, increase safety, harm reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

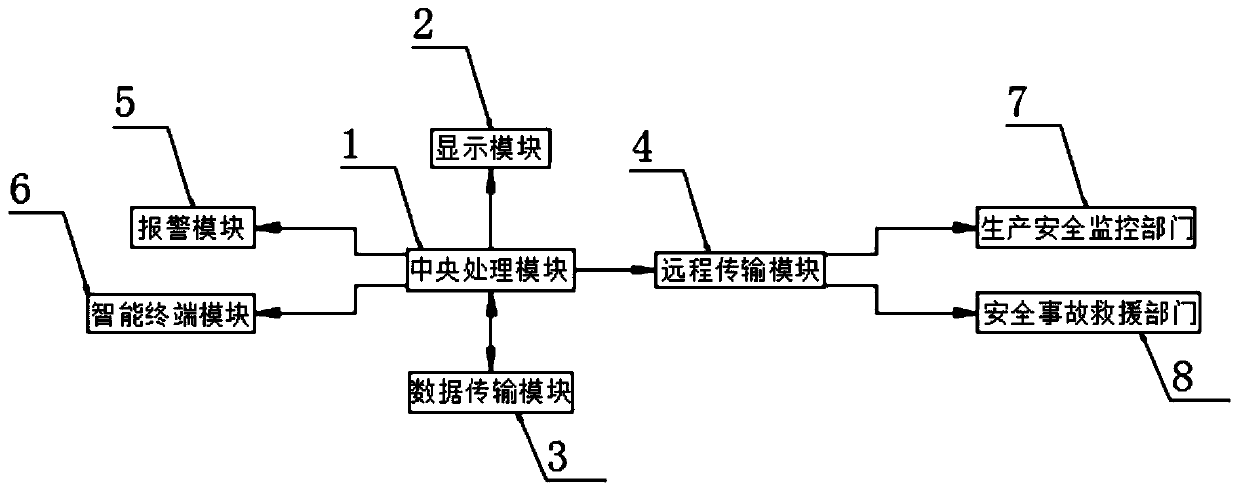

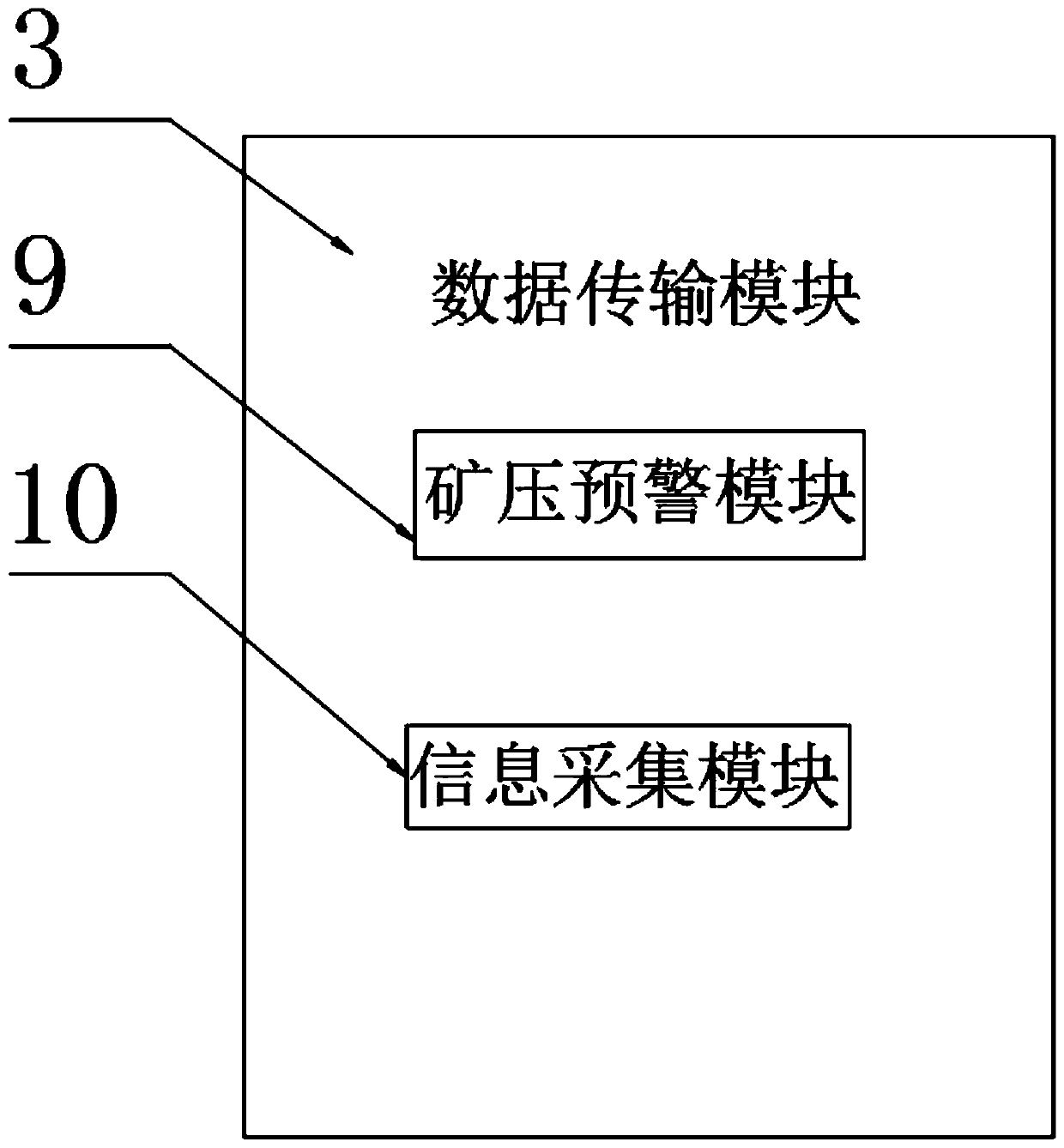

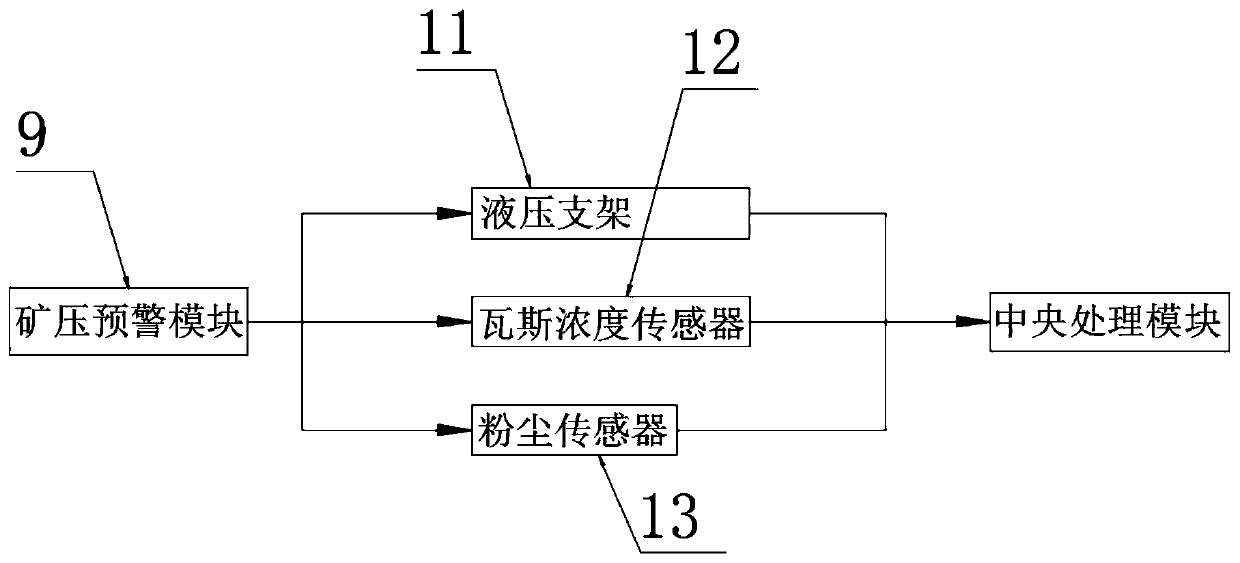

[0025] as attached Figure 1-5 The shown comprehensive mine safety monitoring system includes a central processing module 1, and the output terminal of the central processing module 1 is electrically connected with a display module 2, a data transmission module 3, a remote transmission module 4, an alarm module 5 and an intelligent terminal Module 6, the output end of the remote transmission module 4 is electrically connected to the production safety monitoring department 7 and the safety accident rescue department 8, the data transmission module 3 includes a mine safety early warning module 9 and an information collection module 10, the mine safety The output end of the early warning module 9 is electrically connected to a hydraulic support detection end 11, a gas concentration sensor 12, and a dust sensor 13, and the output end of the information collection module 10 is electrically connected to a humidity sensor 14, a wind speed sensor 15, and a carbon monoxide sensor 16. T...

Embodiment 2

[0029] as attached Figure 1-5 The shown comprehensive mine safety monitoring system includes a central processing module 1, and the output terminal of the central processing module 1 is electrically connected with a display module 2, a data transmission module 3, a remote transmission module 4, an alarm module 5 and an intelligent terminal Module 6, the output end of the remote transmission module 4 is electrically connected to the production safety monitoring department 7 and the safety accident rescue department 8, the data transmission module 3 includes a mine safety early warning module 9 and an information collection module 10, the mine safety The output end of the early warning module 9 is electrically connected to a hydraulic support detection end 11, a gas concentration sensor 12, and a dust sensor 13, and the output end of the information collection module 10 is electrically connected to a humidity sensor 14, a wind speed sensor 15, and a carbon monoxide sensor 16. ,...

Embodiment 3

[0032] as attached Figure 1-5 The shown comprehensive mine safety monitoring system includes a central processing module 1, and the output terminal of the central processing module 1 is electrically connected with a display module 2, a data transmission module 3, a remote transmission module 4, an alarm module 5 and an intelligent terminal Module 6, the output end of the remote transmission module 4 is electrically connected to the production safety monitoring department 7 and the safety accident rescue department 8, the data transmission module 3 includes a mine safety early warning module 9 and an information collection module 10, the mine safety The output end of the early warning module 9 is electrically connected to a hydraulic support detection end 11, a gas concentration sensor 12, and a dust sensor 13, and the output end of the information collection module 10 is electrically connected to a humidity sensor 14, a wind speed sensor 15, and a carbon monoxide sensor 16. , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com