Impeller built-in electric pump adjustable blade

A built-in, adjustable technology, applied in the field of electric pumps, can solve the problems of loose electric pump blade adjustment structure, complex electric pump blade adjustment structure, difficult installation and maintenance, etc., to achieve low manufacturing cost, reduce vibration, and reduce requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

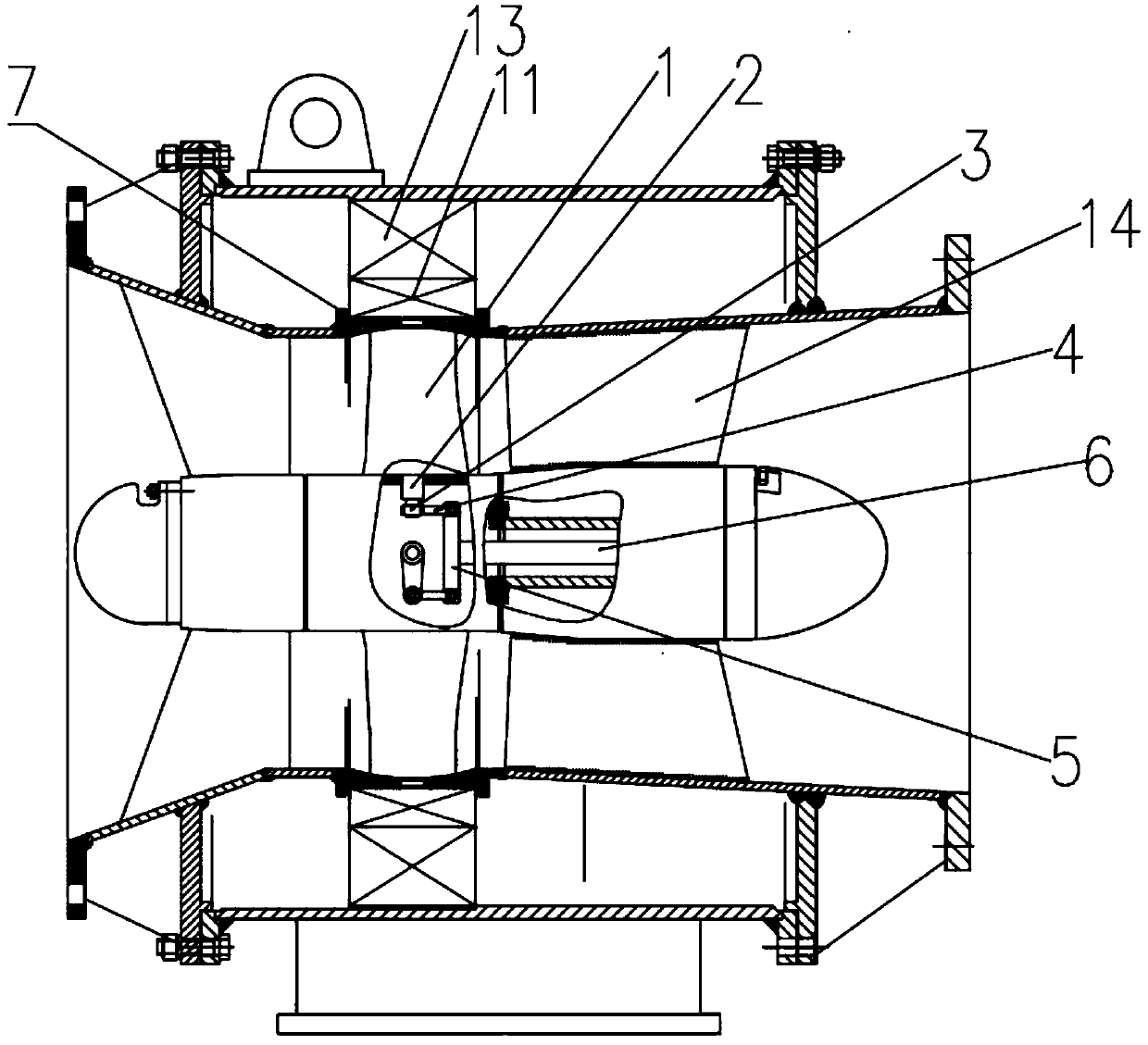

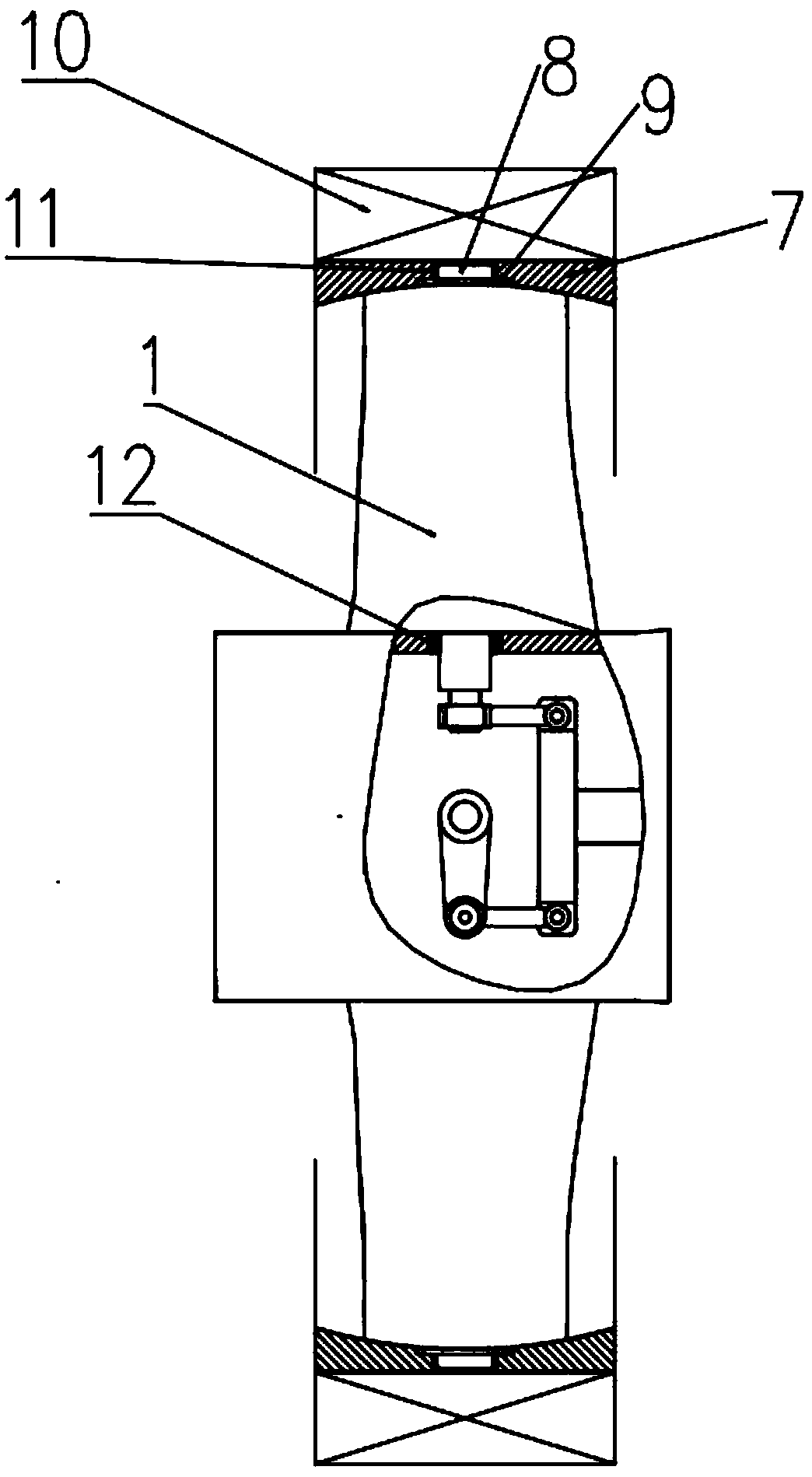

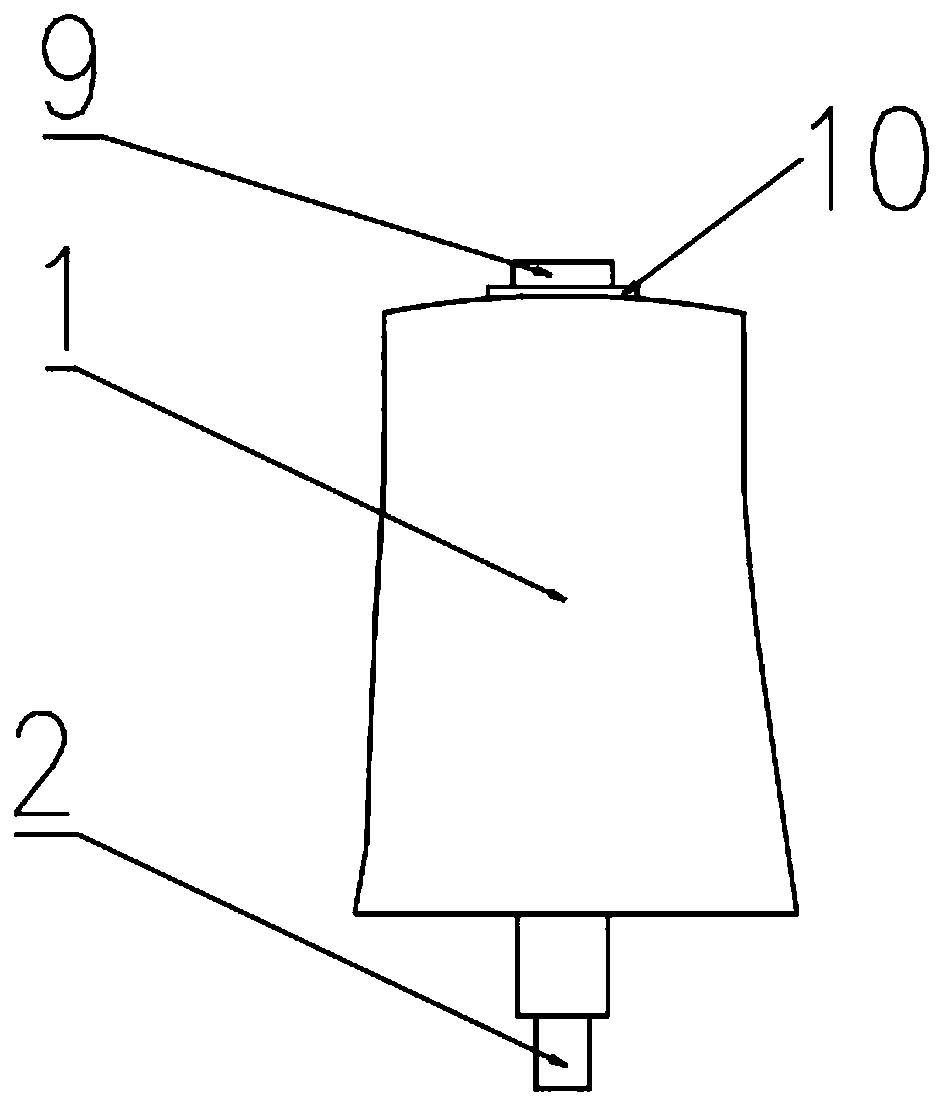

[0023] refer to Figure 1-4 , a built-in impeller electric pump adjustable blade, including a blade body 1, characterized in that the blade body 1 realizes angle adjustment through a lever-type regulator structure, and the lever-type regulator structure includes a control shaft provided at the root of the blade body 1 2. The other end of the control shaft 2 is connected to the crank 3 through the second sliding bearing 12, the other end of the crank 3 is connected to one end of the connecting rod 4 in rotation, and the other end of the connecting rod 4 is connected to the operating frame 5 in rotation. The operating frame 5 is provided with a dowel 6 which drives the operating frame 5 to move.

[0024] In this embodiment, the blade body 1 adopts a spherical blade, and there is a small gap between the outside of the blade body 1 and the spherical inner cavity inside the rotor inner ring 7, and the outside of the blade body 1 is provided with a force transmission shaft 8 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com