Double shunt high torque flat double gear box and distribution box average load adjusting method thereof

A high-torque, gear box technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of low transmission torque, limited shaft diameter, poor reliability, etc., to improve the safety factor and improve the bearing capacity. , the effect of meshing backlash consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

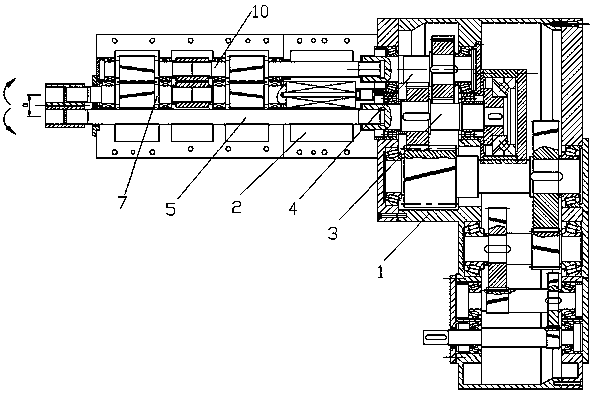

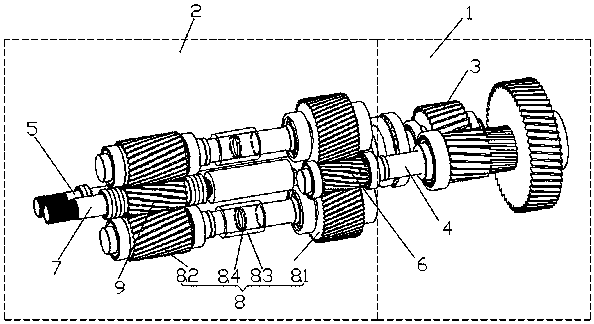

[0025] see figure 2 , the present invention relates to a double-split high-torque flat double gearbox, including a reduction box 1 on the right side and a distribution box 2 on the left side. The reduction box 1 is used for power reduction, and the distribution box is used for torque distribution.

[0026] The input shaft of the gearbox 1 is connected to the motor, and the torque transmitted by the motor is decelerated in three stages, and 50% of the torque is transmitted to the left and right two parallel first transmission output shafts 3 and the second transmission output shaft 4, wherein the first transmission output shaft 3 and the second transmission output shaft 4 The 50% torque of a transmission output shaft 3 is directly transmitted to the first output shaft 5 of the distribution box 2 through an involute spline, and the end of the second transmission output shaft 4 extending into the distribution box 2 is provided with a first distribution gear 6 , the distribution ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap