Non-contact nondestructive measurement system and method for surface type of highlight object

A measurement system and non-contact technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as spraying, impossibility, and difficult mechanical measurement methods, and achieve the effect of eliminating highly reflective areas and expanding the measurement field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

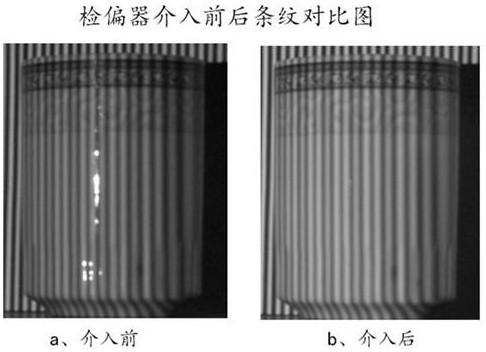

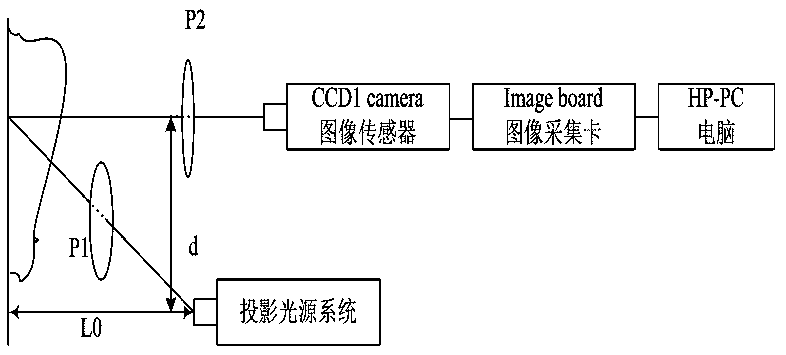

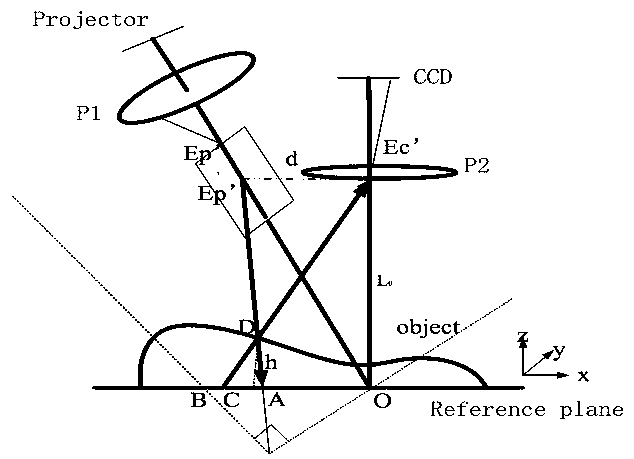

[0034] see Figure 1 to Figure 6, a non-contact non-destructive measurement system for high-gloss object surface, which includes a projection light source system, a polarizer, an image sensor, an image acquisition card and a computer; the polarizer includes a polarizer P1 and an analyzer P2, and its measurement system The projection system in is composed of a projection light source and a polarizer P1, and the imaging system in the measurement system is composed of an image sensor and a polarizer P2; the image sensor is an area array detector that receives a deformed grating image, and the image sensor receives The deformed grating image is transmitted to the computer by the image acquisition card to form a picture; the projected light source is an area array of natural light whose intensity is distributed sinusoidally, and the grating lines of the stripes are perpendicular to the reference plane.

[0035] The non-contact non-destructive measurement method of a high-gloss obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com