Multi-path material discharger and operation speed control method thereof

A technology of operating speed and control method, applied in electric speed/acceleration control, fertilizer distributor, planter parts, etc., can solve the problems of troublesome material collection, inaccurate calibration, troublesome operation, etc. The effect of uniform spreading and short circulation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

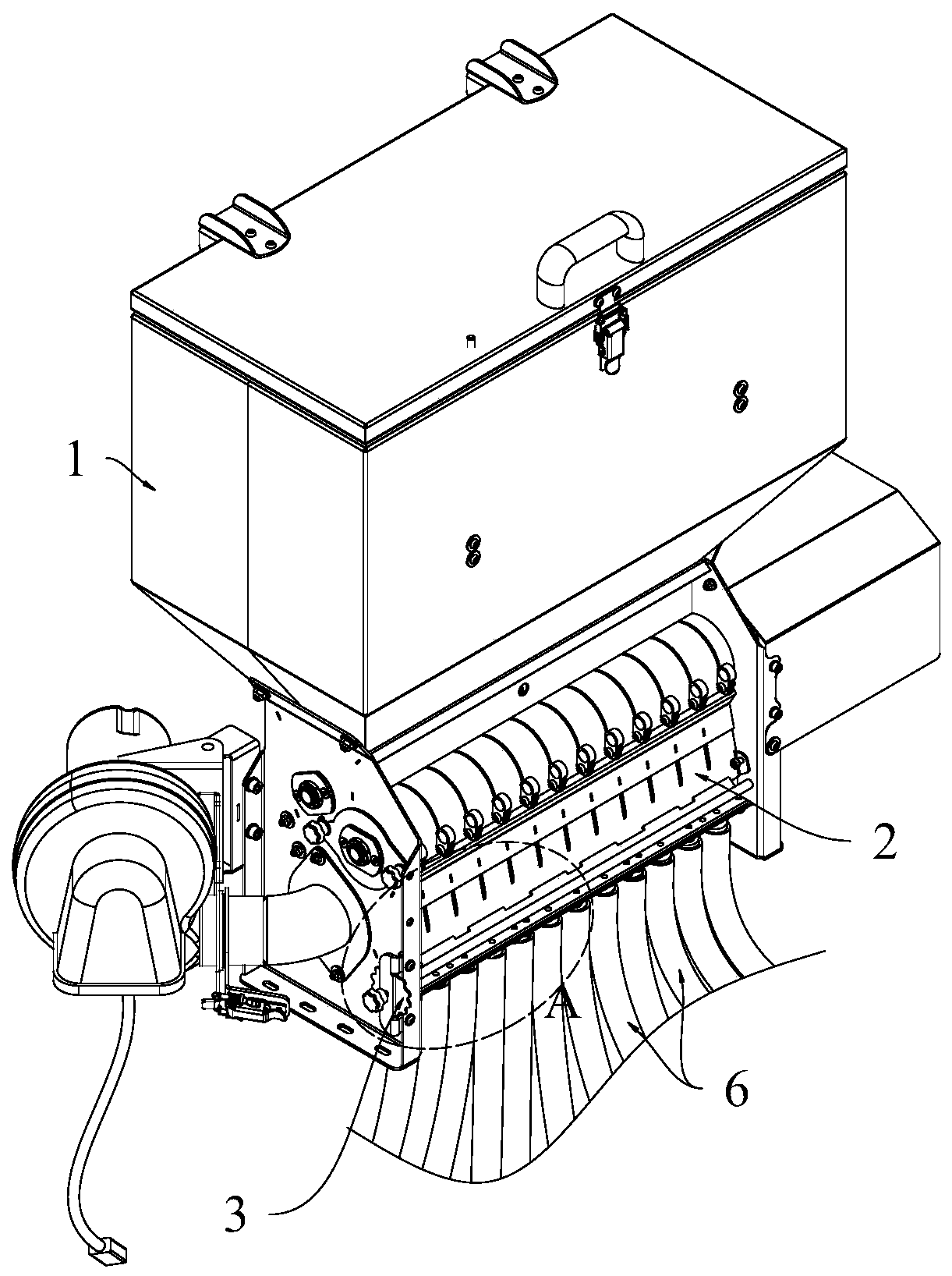

[0047] as attached figure 1 The multi-way discharger shown is used to accommodate agricultural materials such as seeds and fertilizers, and can distribute the flow of agricultural materials in it to multiple discharge pipes 6 stably and continuously, so that the multi-way discharger loaded with The agricultural tillage and sowing machinery of the machine can sow / fertilize evenly, ensuring the quality of sowing or fertilizing operations.

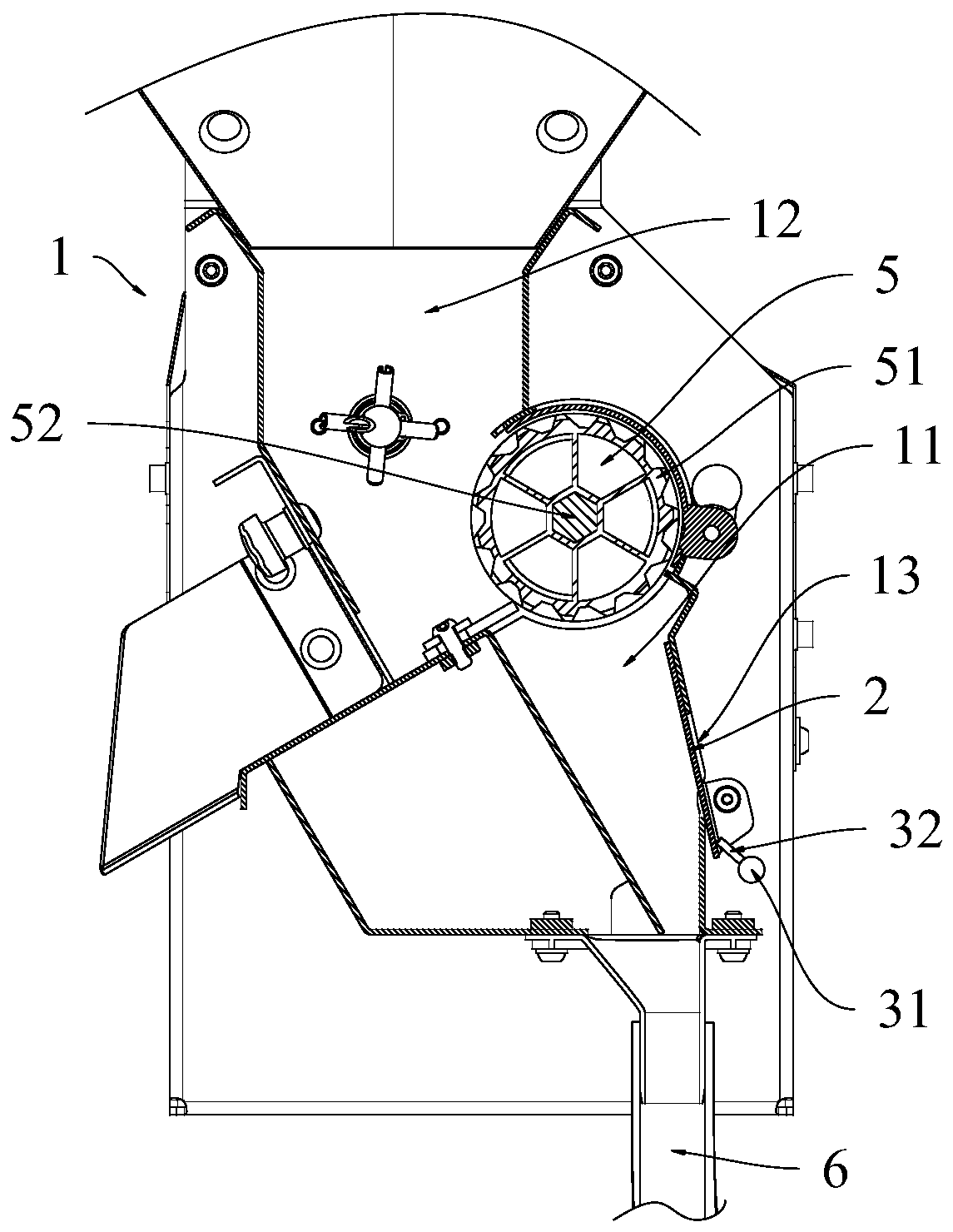

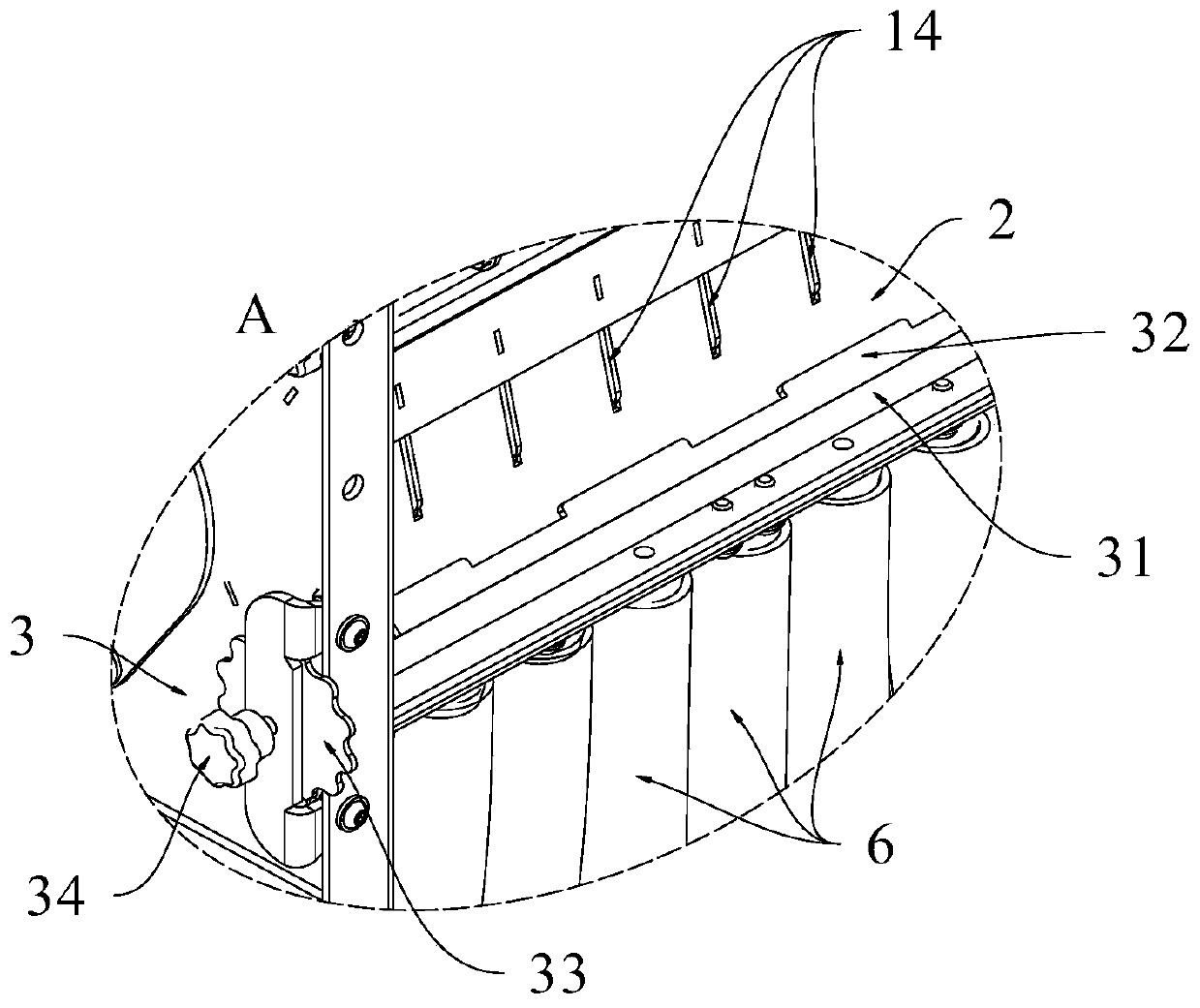

[0048] Specifically, the multi-way discharger includes a chassis 1, as attached figure 2 As shown, in the cabinet 1, a material cabin 12 and a plurality of discharge channels 11 arranged in a linear array are formed, and a distribution structure 5 is installed in the cabinet 1, and the distribution structure 5 is equipped with a distribution wheel shaft 52 and an installation A plurality of distribution wheels 51 on the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com